Hi all,

The Pylontech battery modules have been supplied with 25mm2 interconnects and 2 * 2m 25mm2 battery cables. The MP installation manual however states at least 70mm2 is required.

The Pylontech documentation states max. continuous Charge/Discharge Current (A) of 100A (recommended 80A) which these 25mm2 cables - apparently - can handle. The Victron documentation for Pylontech, if I'm reading it correctly, seems to suggest implicitly that the standard/supplied 25mm2 interconnects (and presumably 2m battery cables) are suitable.

This system will have a RS450/100 and PV inverter installed (with similarly sized arrays on both). I intend to limit the charge amps for both MultiPlus and RS450/100 to 50A ea, ie. limiting the max charge current to 100A and perhaps set the total max charge current to 100A in DVCC on the Venus GX as well even though I suspect 4 parallel US5000 could handle more (but not the Pylontech supplied cables). Can someone offer some insights whether the standard Pylontech 25mm2 cables are adequate when total charge/discharge currents are limited to max 100A and fused with 160A?

I've read a couple of posts here on the forum and while the Pylontech cables (apparently) are rated for higher currents (even though they are only 25mm2), I do sense not everyone agrees these are suitable cables.

For easy ref:

https://community.victronenergy.com/questions/41642/pylontech-battery-cable-spec.html https://community.victronenergy.com/questions/30915/pylontech-cable-size.html https://community.victronenergy.com/questions/148564/multiplus-2-485000-with-pylontech-us5000.html https://community.victronenergy.com/questions/161522/multiplus-ii-with-pylontech-stack-cable-and-fuse-c.html https://www.victronenergy.com/live/battery_compatibility:pylontech_phantom

Kind regards,

Jan

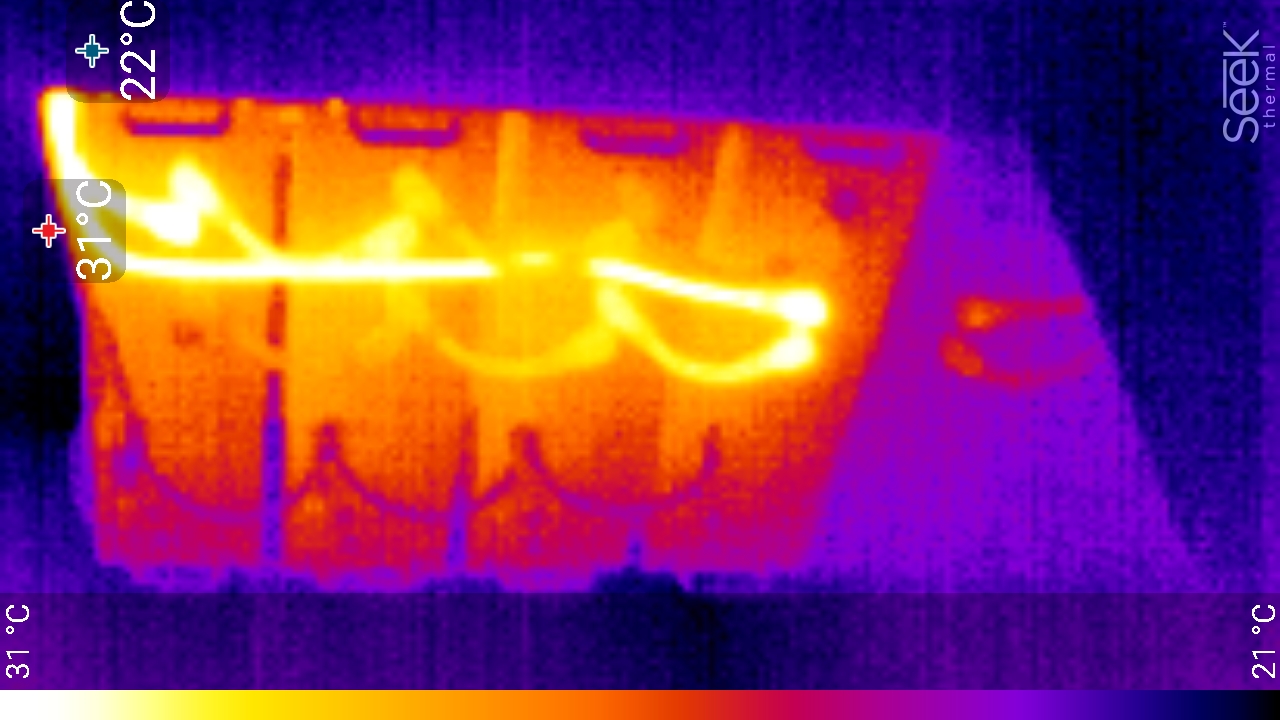

Presumably, given the cable temp (31C or 9C above ambient) and the time period you could work out what the losses are and if you want to upgrade. For the 5000, it would seem likely you'd need 2x sets of 2m cables.

Presumably, given the cable temp (31C or 9C above ambient) and the time period you could work out what the losses are and if you want to upgrade. For the 5000, it would seem likely you'd need 2x sets of 2m cables.