HI All,

Posting this after looking extensively on the forum and contacting Pylontech direct, to no avail.

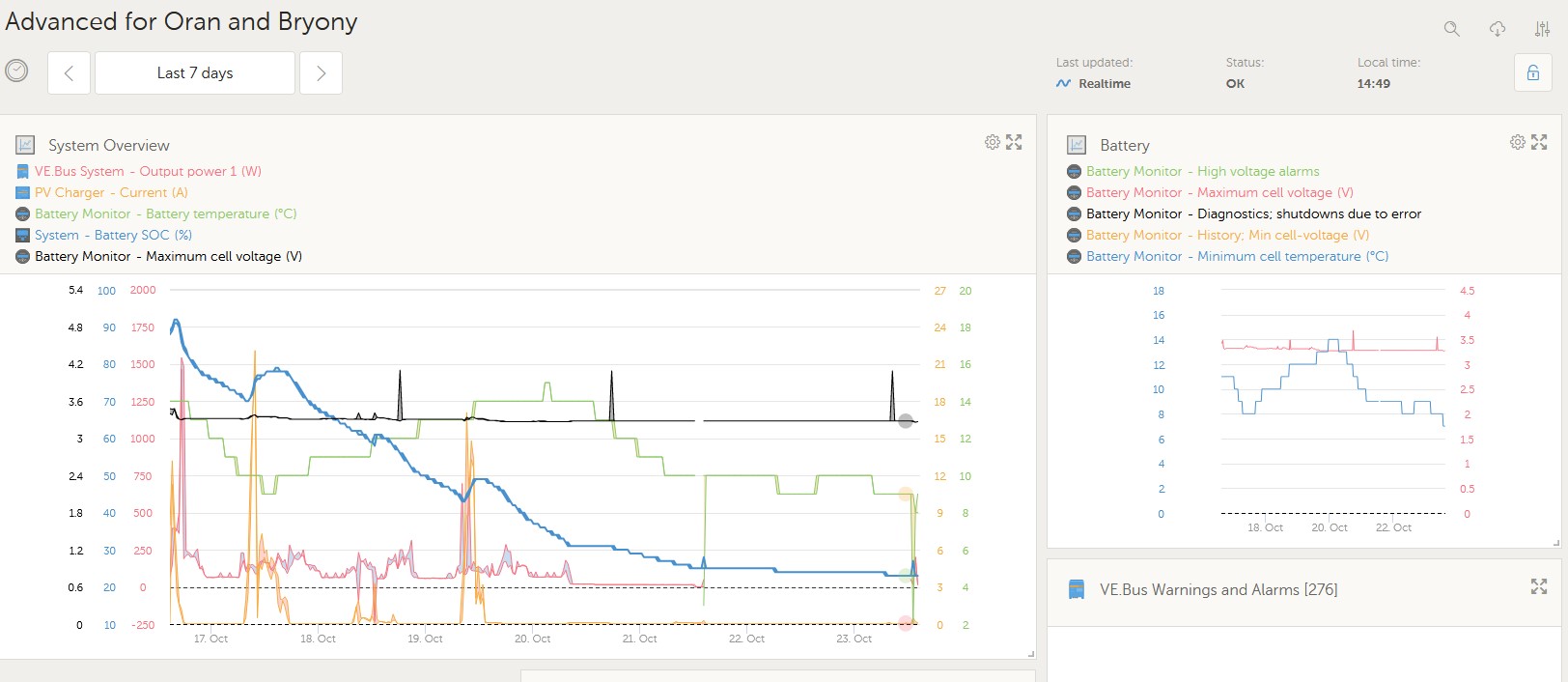

I have a system that is failing to charge the batteries from 23% SOC when the PV array should be giving c.2-3kW and daily production should be of order 8-10kWh.

System is Multiplus 2 48/5000, Cerbo GX, 250/100MPPT, Pylontech USC3000 x4

All the CANbus cabling has been installed a while and was working fine until last week. No obvious issues like mice etc. connections seem fine in VRM and through the cerbo screen onsite.

We had a generator set up until last week but that is currently away for repairs and unavailable until next week. COld weather is approaching so need to get this up and running asap.

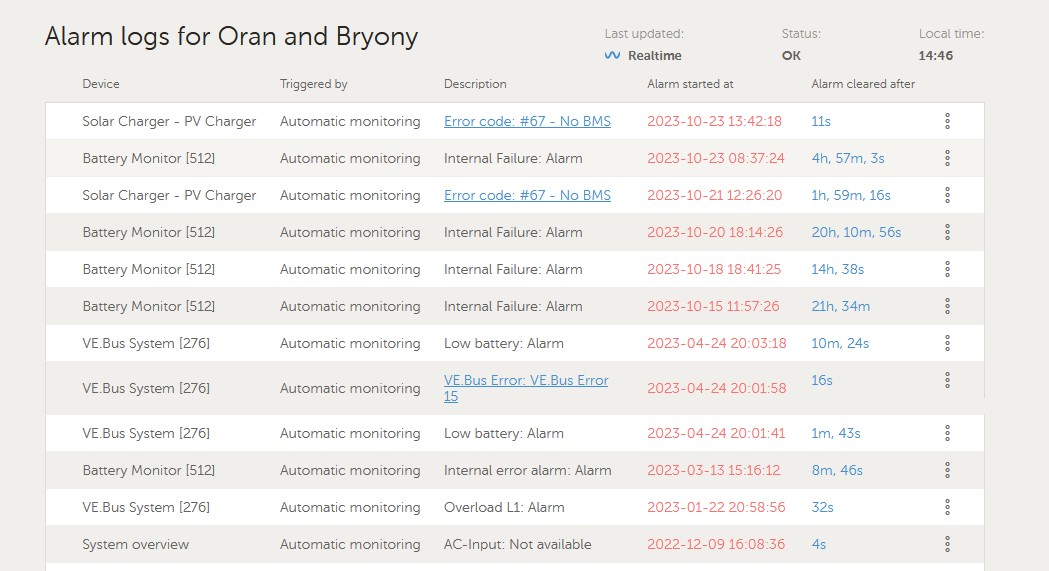

Multiple alarms, some common (Internal Battery Failure) others not so much (codes for the MPPT and BMS hgave only recently appeared).

Updated the MPPT firmware today as per a suggestion on this forum, reset the BMS control, asn per another suggestion. Neither has worked although I did see a change in the PV production up to 20W shortly after I did the updates. Also switching a larger load on seemed to kick the MPPT into action momentarily.

Battery is above 5 degrees so should take charge, there is a 230V heater that keeps them above 7 degrees but that is not going to be an option for much longer unless we get the PV working!

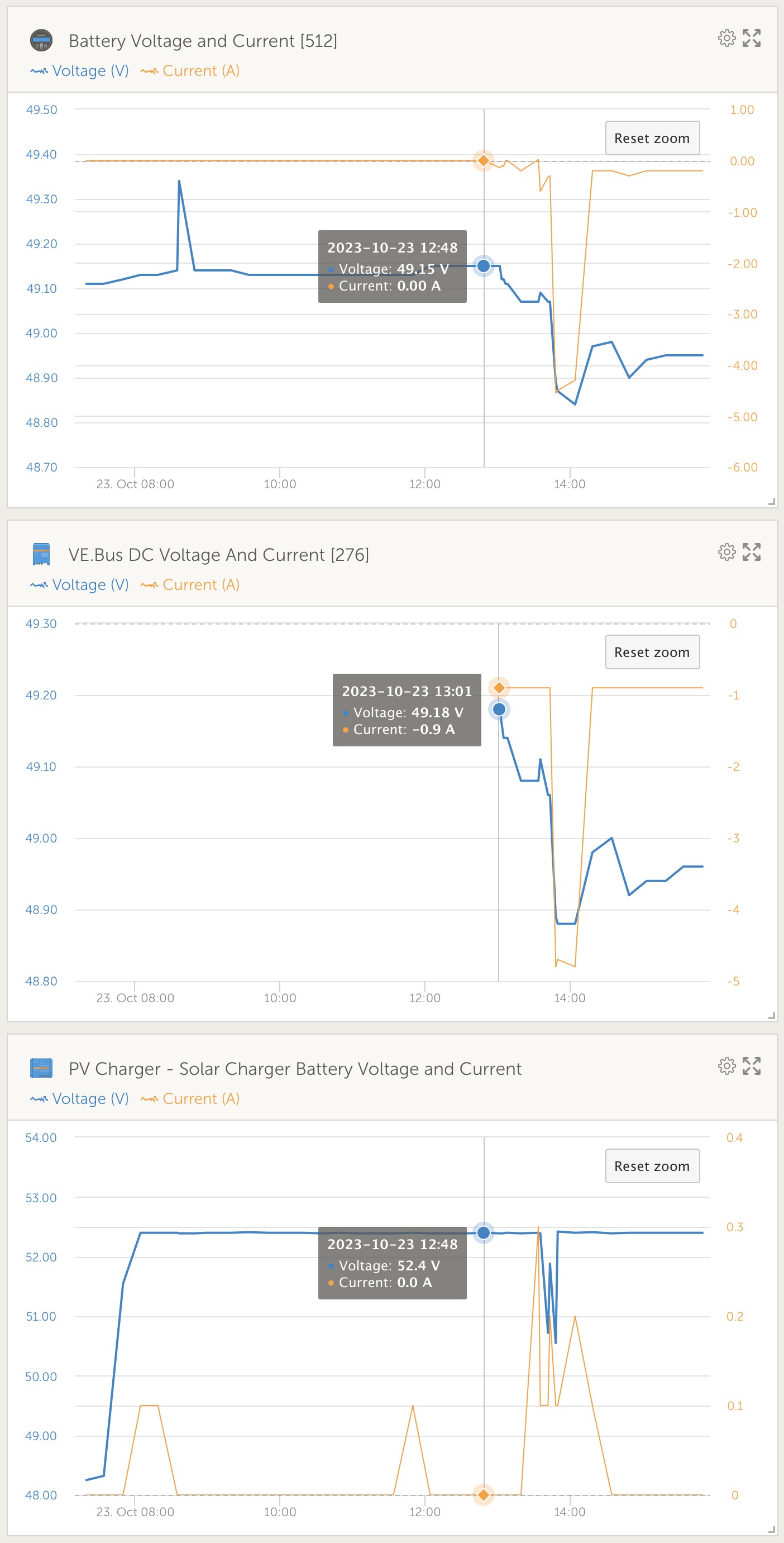

There is a discrepancy between the battery voltage reported via the Cerbo/VRM (c.49V) and that reported by the MPPT through victronconnet locally vie bluetooth (c.52V).

If any victron staff want to have a look that would be amazing @Guy Stewart (Victron Community Manager) @mvader (Victron Energy) the VRM Instance is: 48e7da89496f Images attached below

Many thanks,

Jona