Hello community!

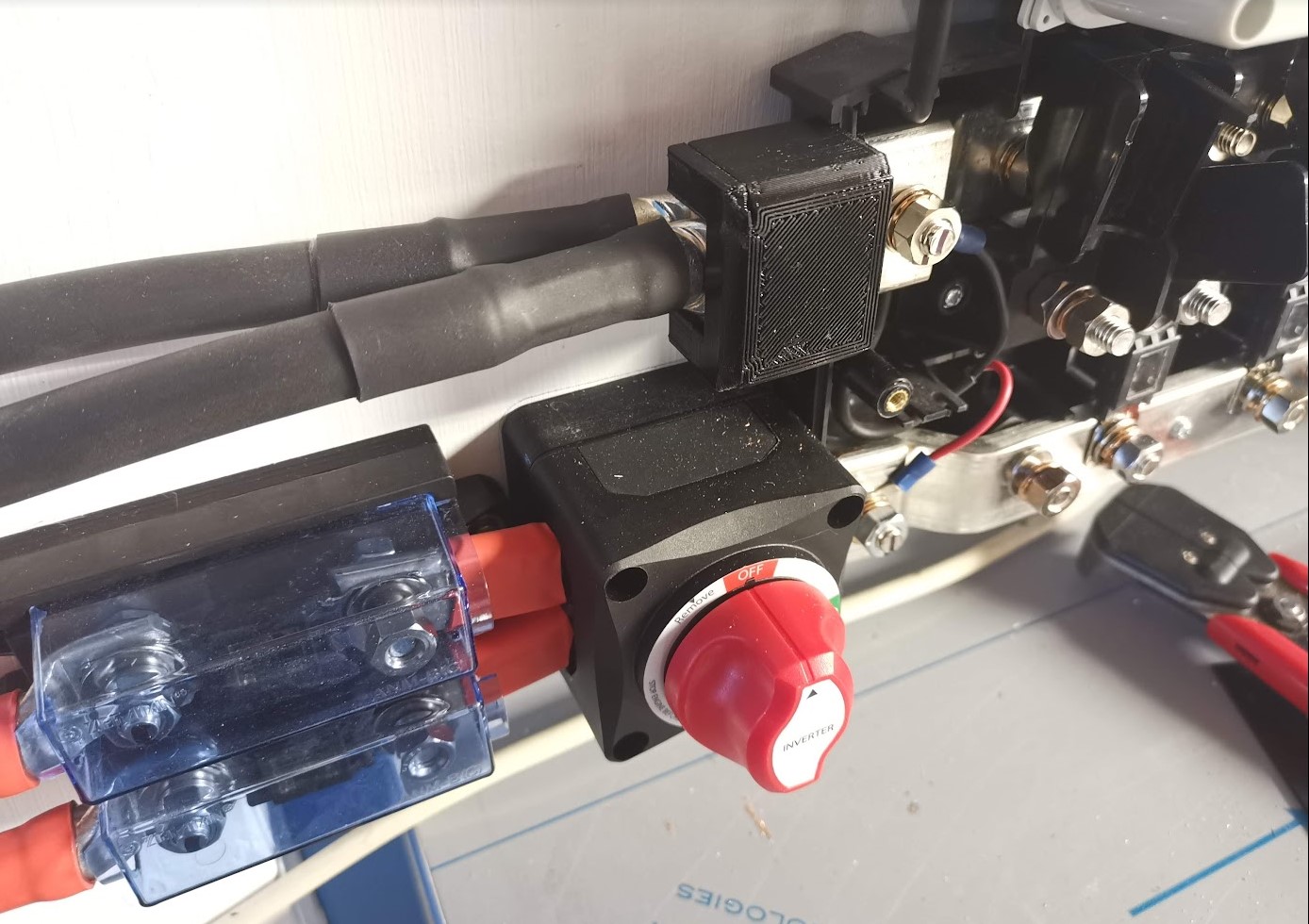

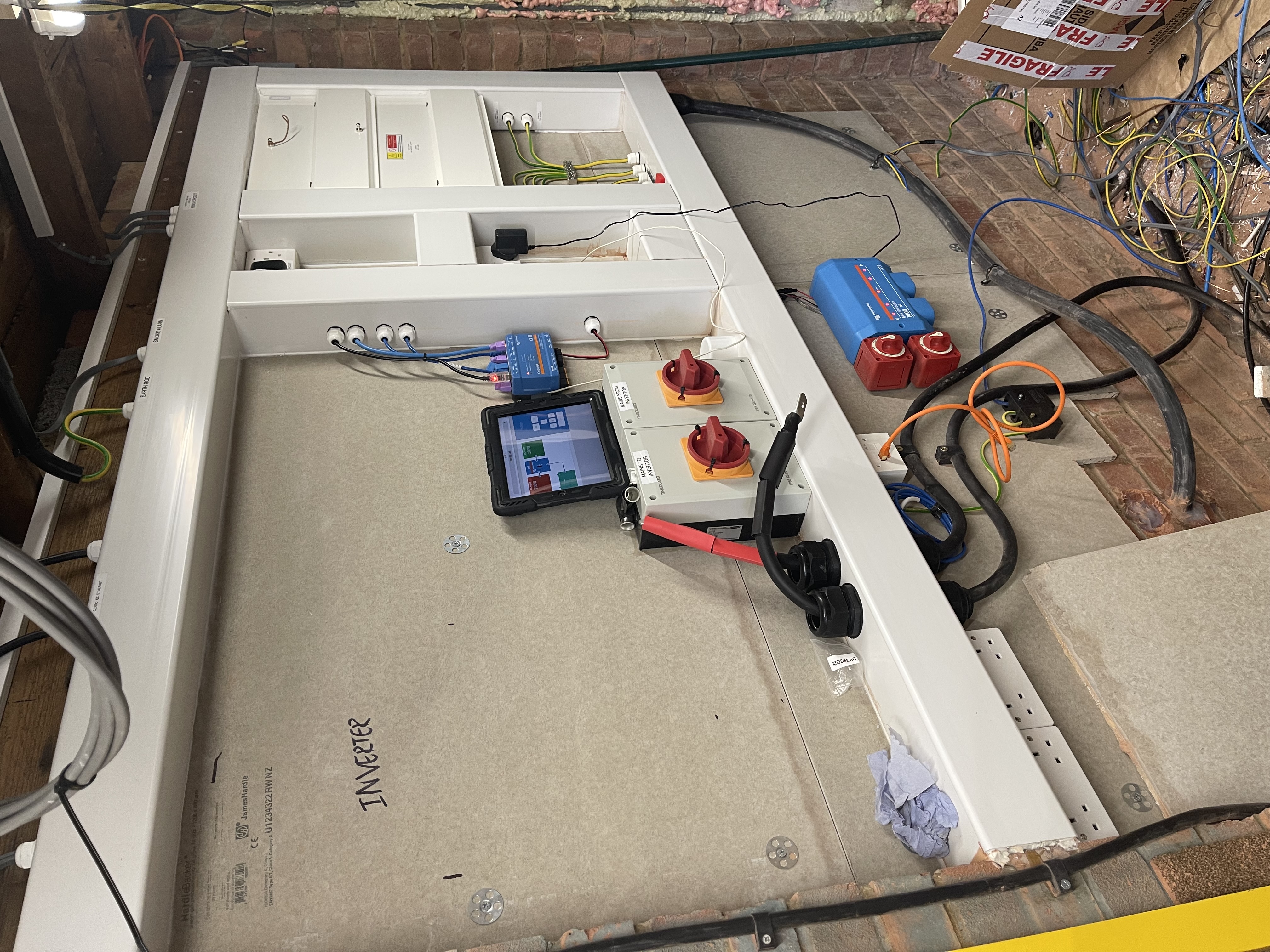

Is anyone using the Victron Battery Switch ON/OFF 275A? https://www.victronenergy.com/battery-isolators-and-combiners/battery-switch-on-off#manuals

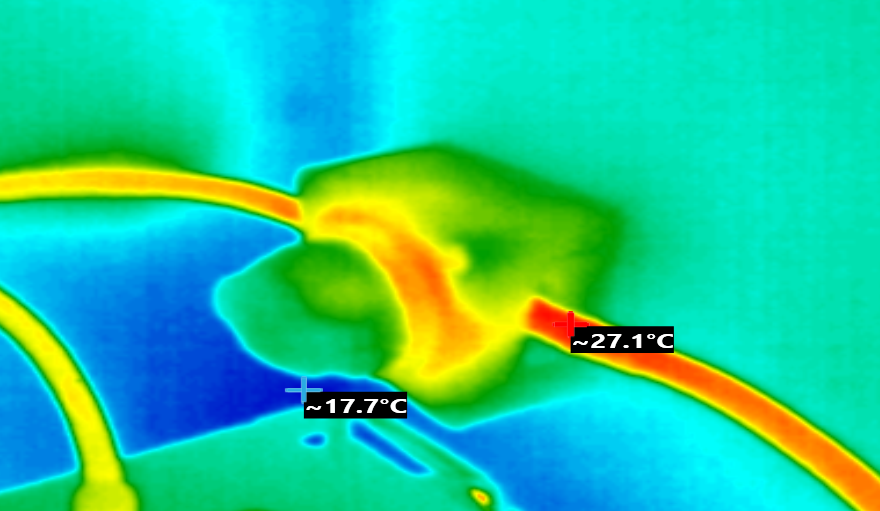

I have used similar looking switches, with similar specs, and my experience is that these get very hot at 48V and 150A (for ambient temp around 20ºC it goes to 110-120ºC). Is that also the case with the original Victron switch? Or can one speak of a better quality? (Switch contact with lower Resistance...)

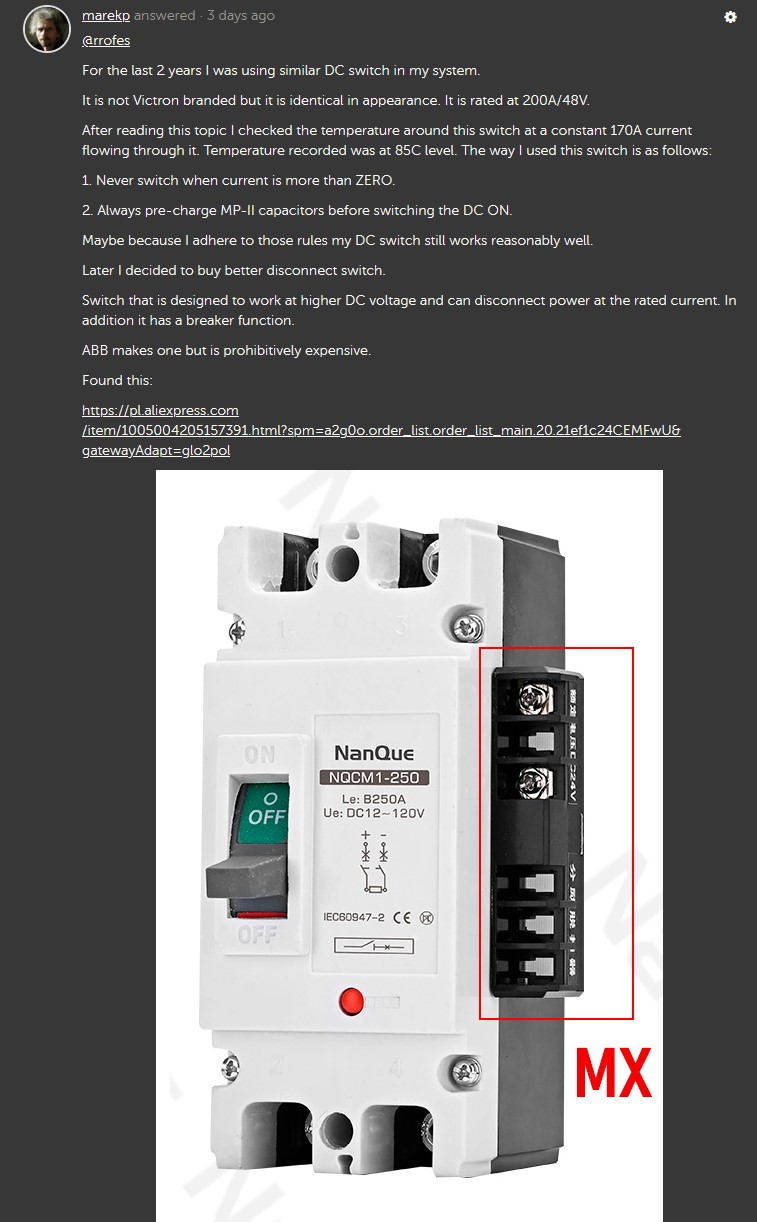

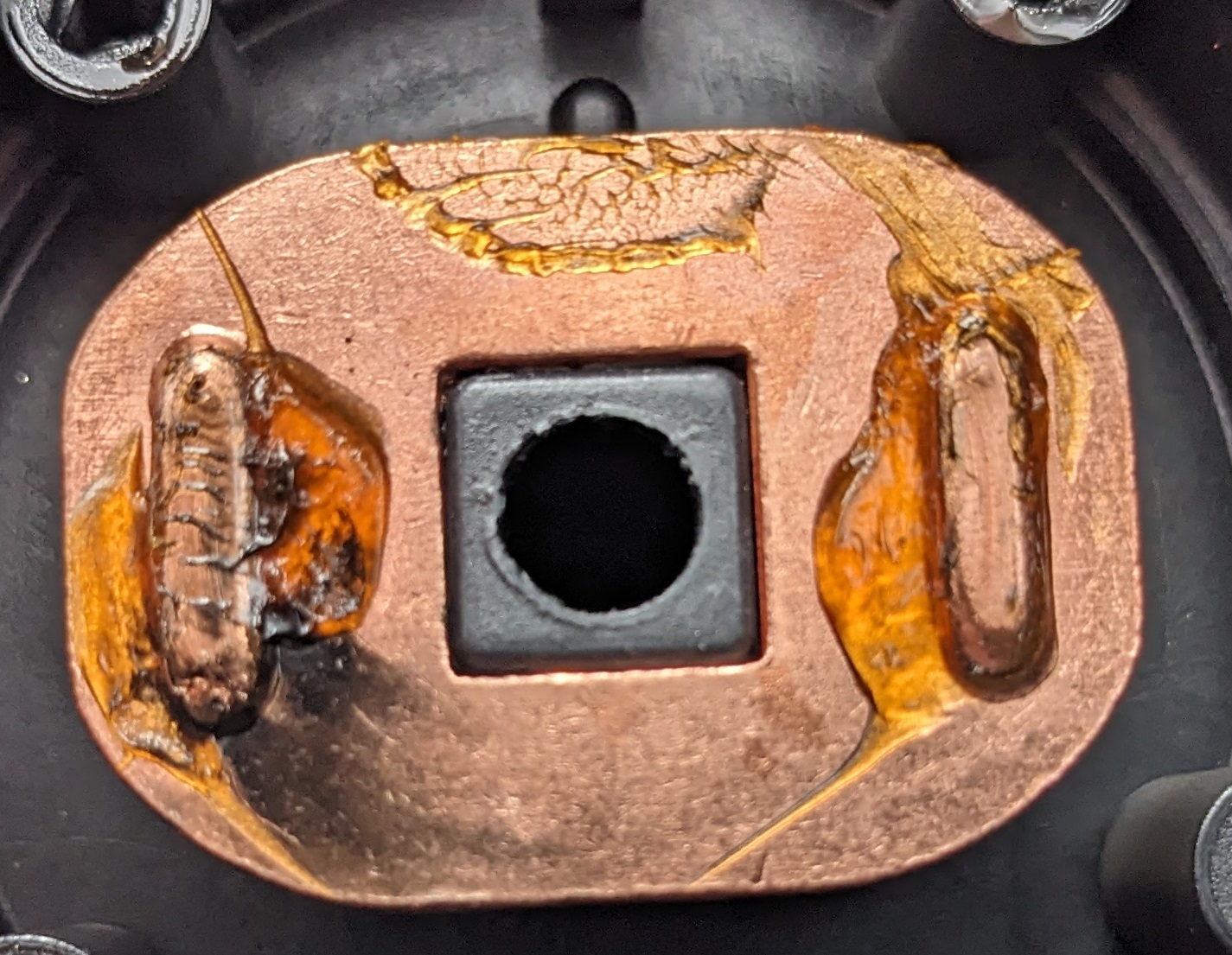

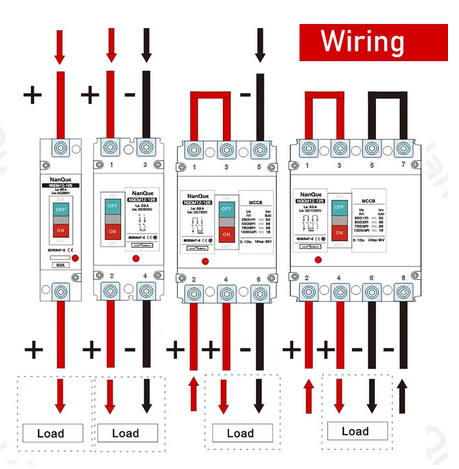

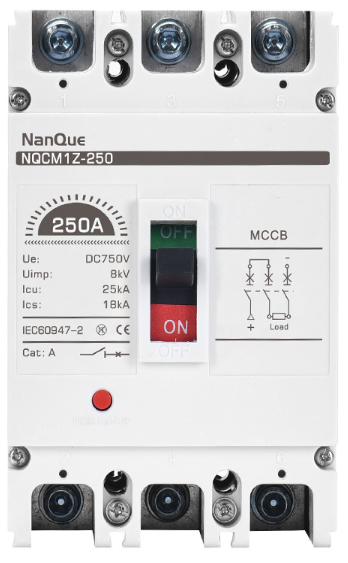

Now look at the symbol on the breaker I suggested:

Now look at the symbol on the breaker I suggested: