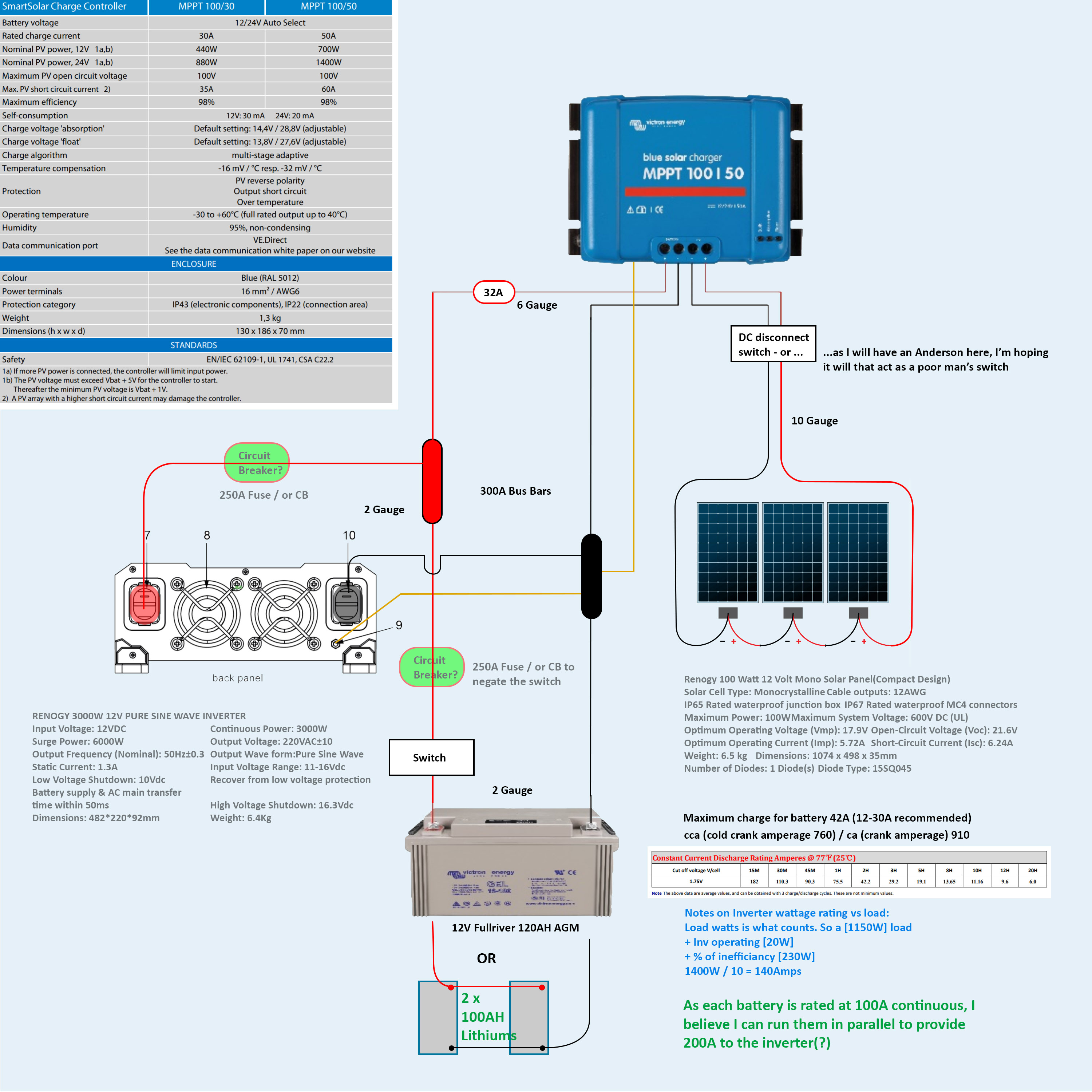

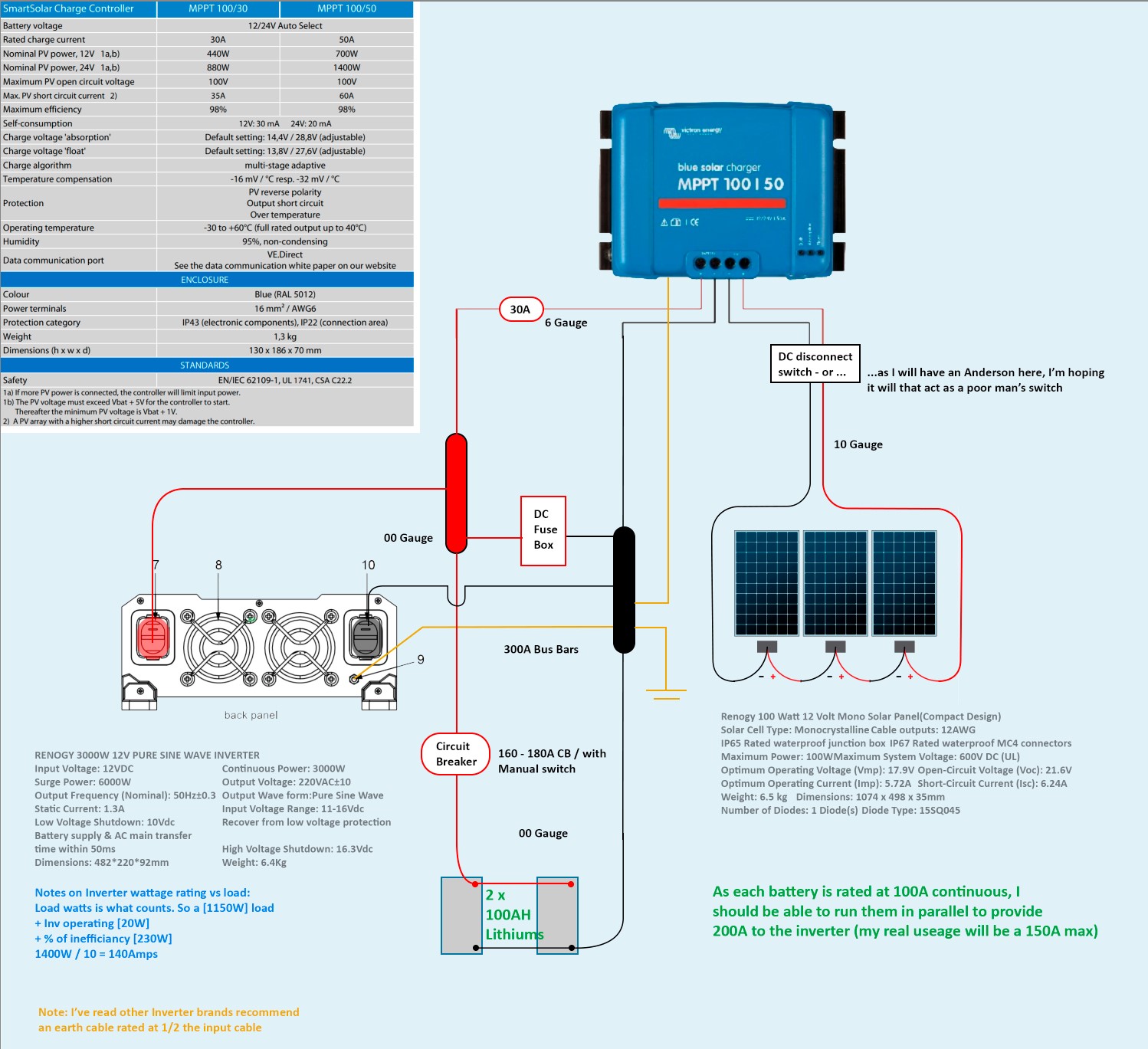

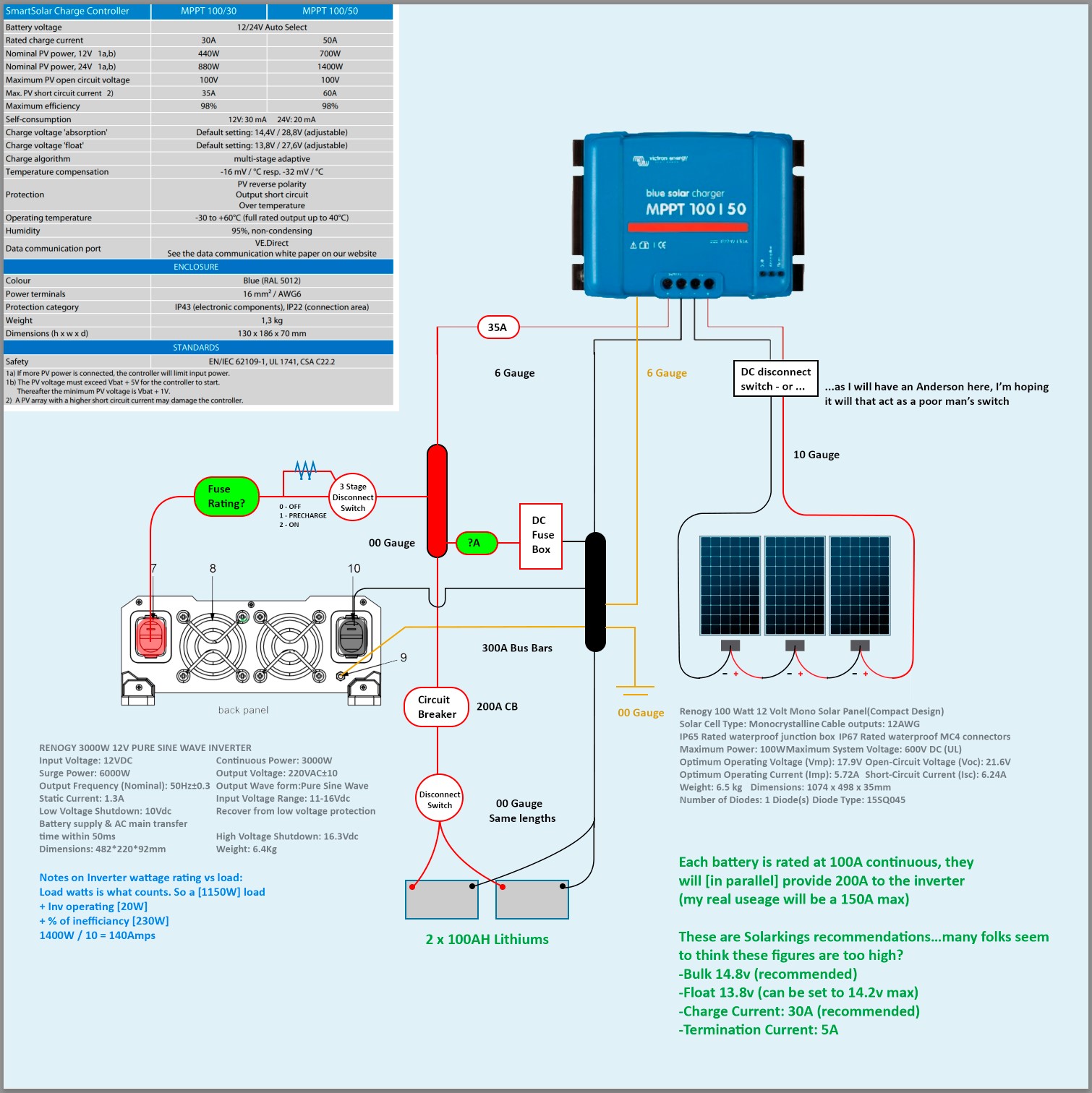

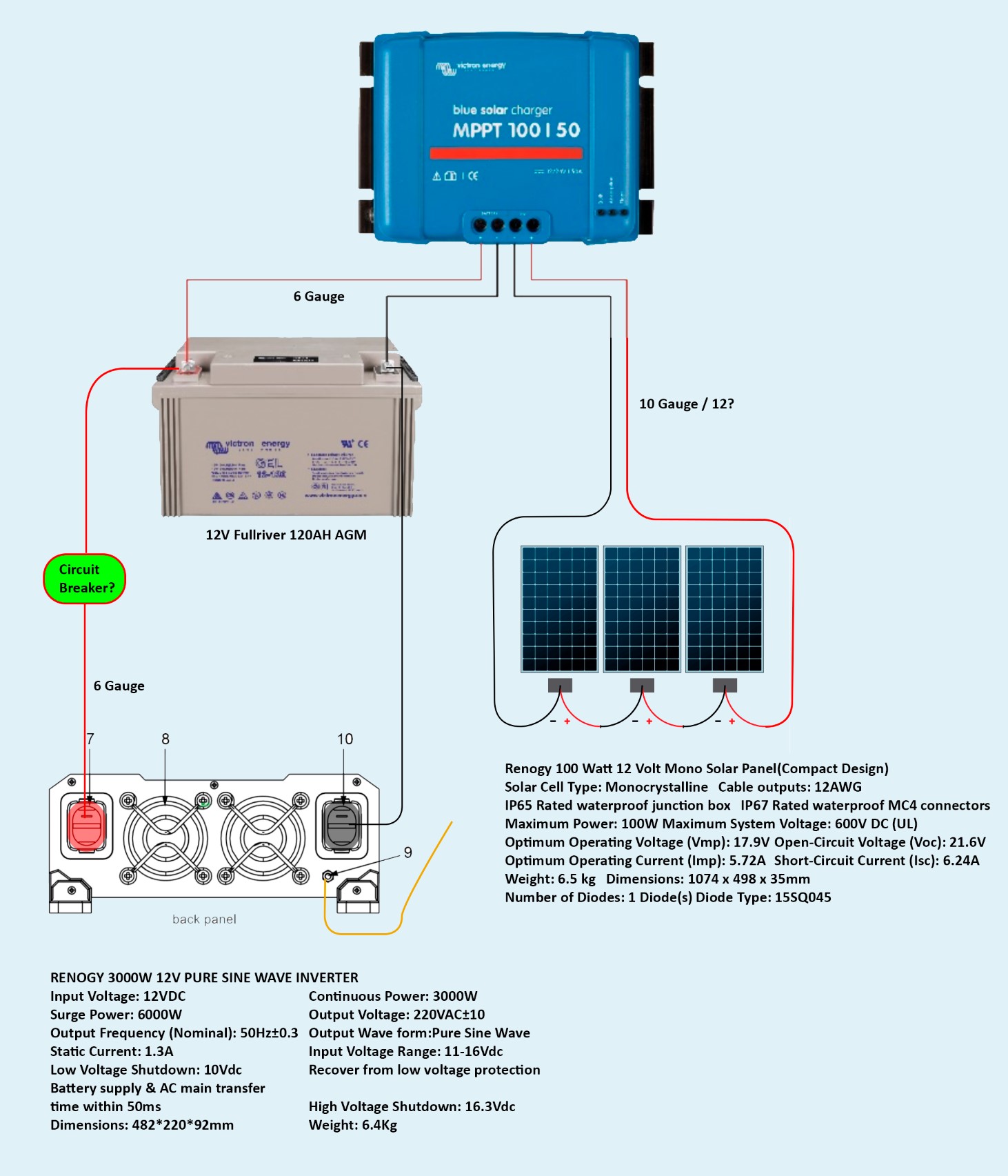

Hey guys, this is the very simple setup I intend to run in the coming weeks - can you please help me with the following:

1. Should I have a circuit breaker (as depicted)? And/or, any other protective devices in the diagram - and if so, what type/rating?

1. Should I have a circuit breaker (as depicted)? And/or, any other protective devices in the diagram - and if so, what type/rating?

2. The system will be contained within a car for 85% of the time, I assume I should Ground the Inverter and MPPT to the vehicle (wherever I can find good contact). Though, the other 15%, it will be completely standalone at a campsite without being grounded...which I assume is the case for many setups?

3. The Panels come with some 12 Gauge, I assume that's fine to run there on? 4. ...anything wrong with the setup, improvements, suggestions?

Many thanks in advance - I really appreciate it (particularly @seb71 for getting me on the path :) ).