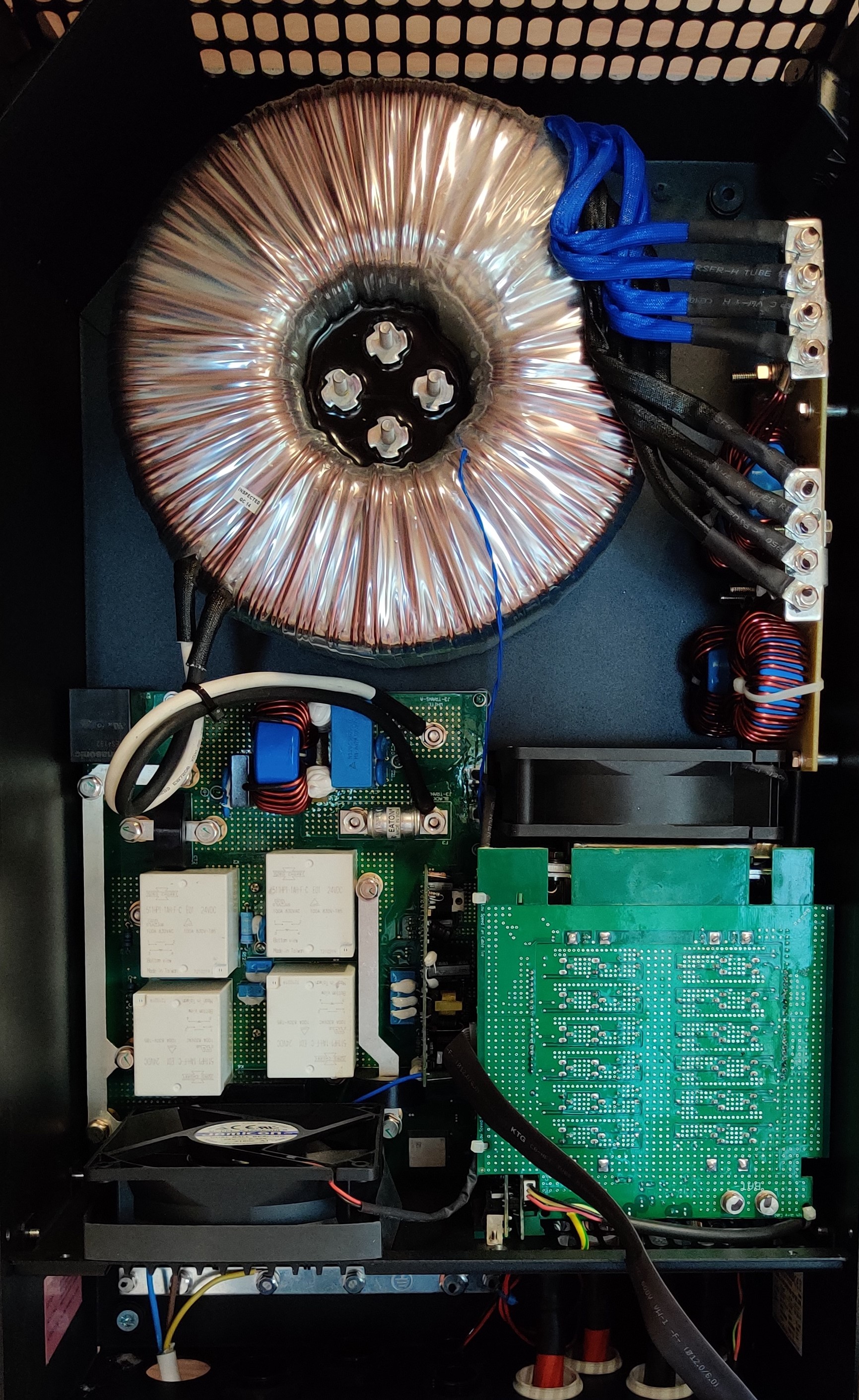

Hi all, as per the topic, I own Multiplus II 48/5000/70, with MPPT and a 48V battery bank.

Things are working as expected, so no problems with configuration.

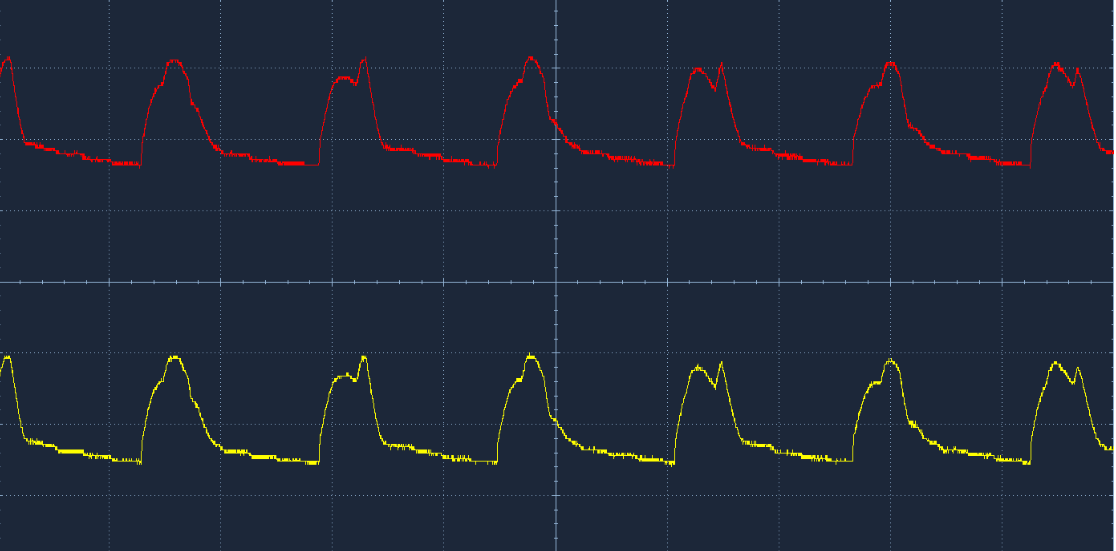

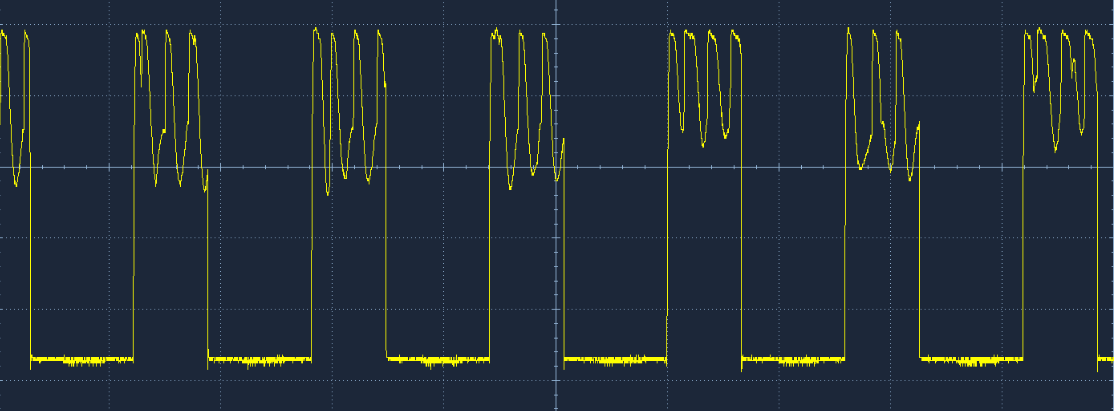

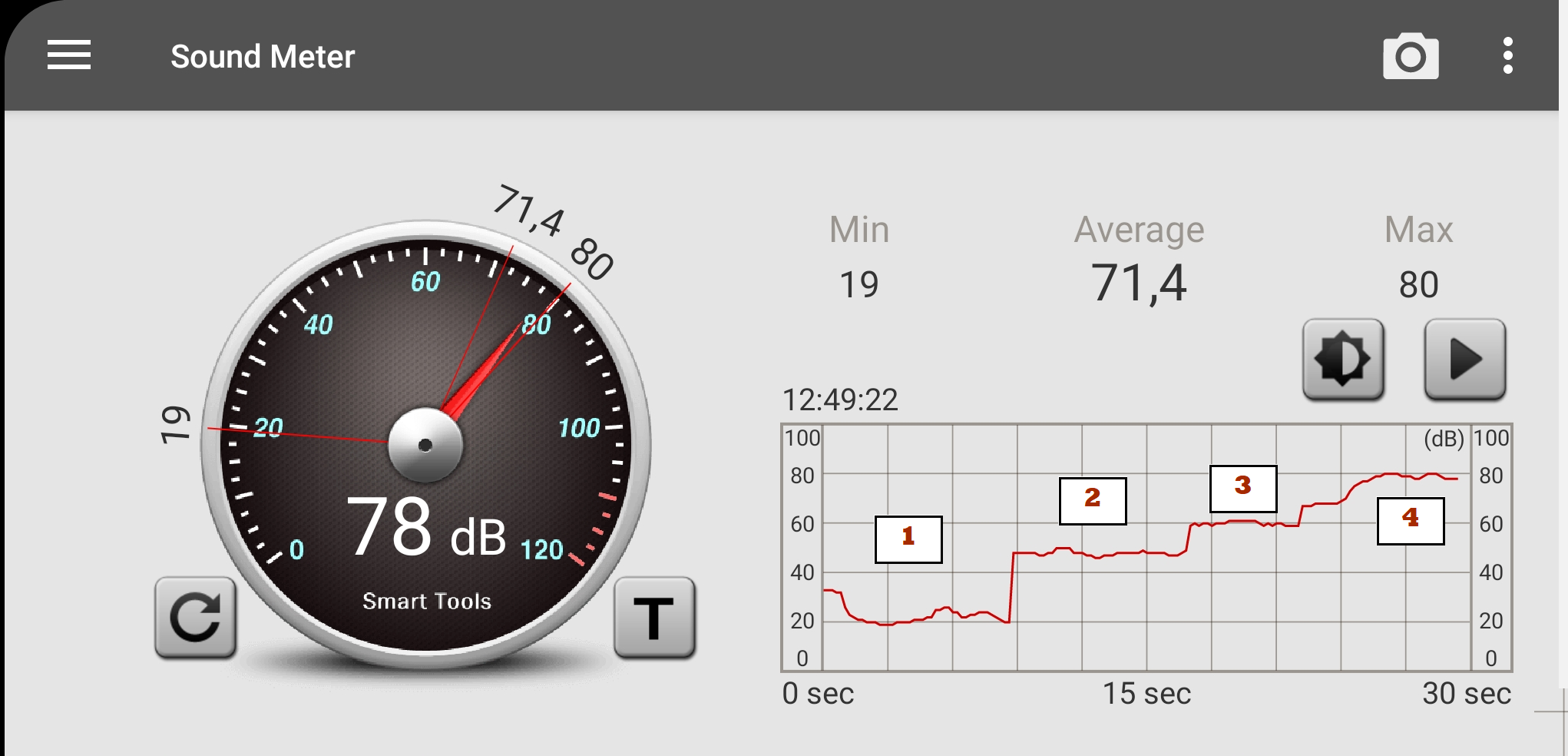

The Fan also switches on when having a load of around above 2kw for more then 30-40 seconds (and I also believe that that is in order). However - I am not confirmable with the noise of the actual fan - the thing is loud and I do know that there are many fans on the market that have different bearings in order to lower the noise.

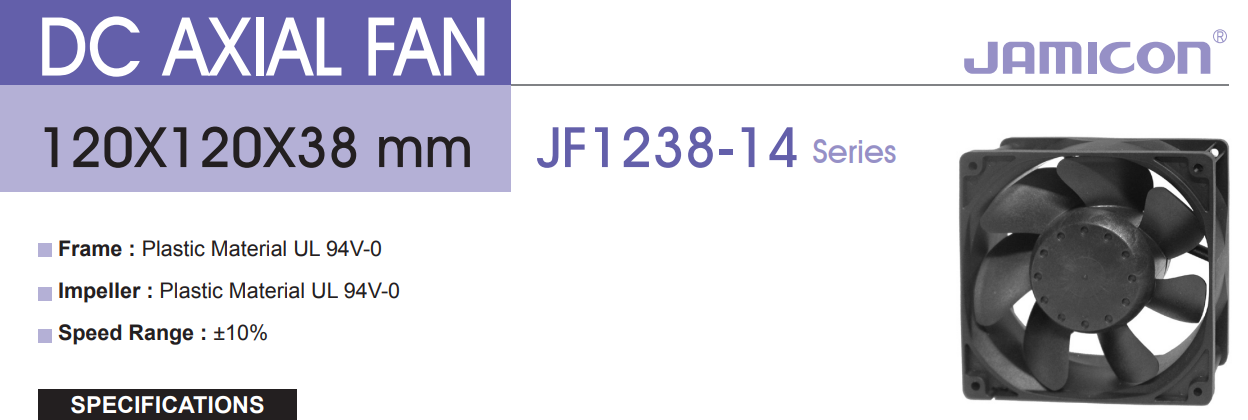

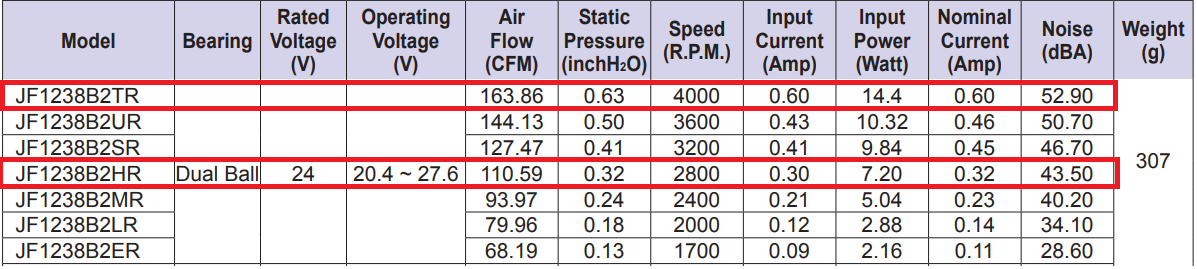

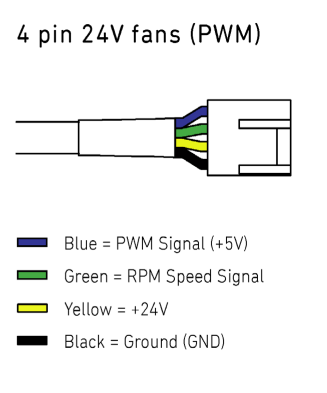

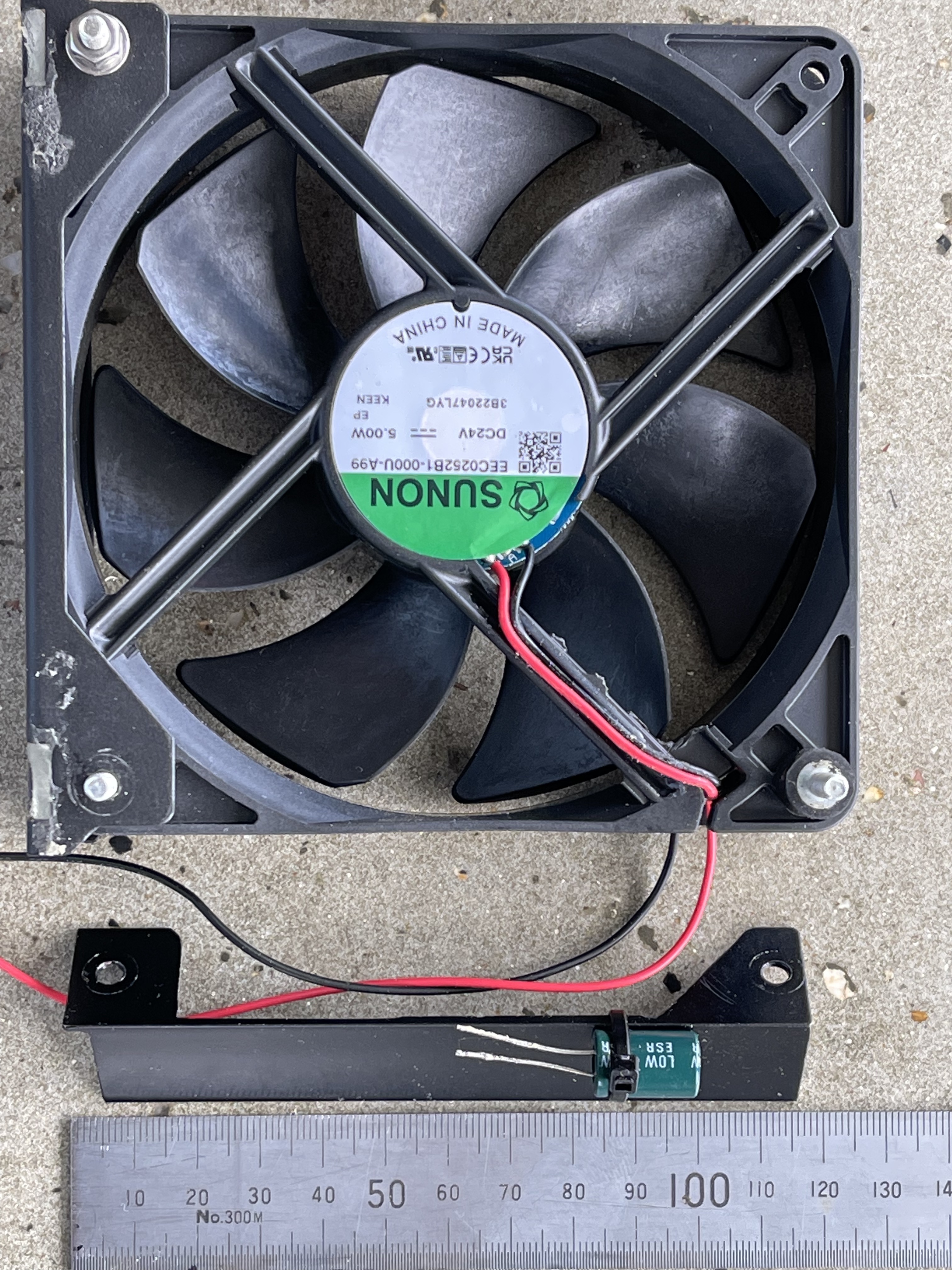

Can anyone advise if the fan in question is 24V DC or 12V DC and confirm the dimensions (if I'm not mistaken, it should be 120x120x38mm)?

Thanks in advance

Bobby

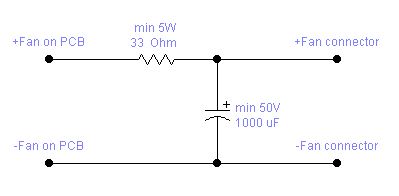

and a third rubber mount to secure the fan.

and a third rubber mount to secure the fan.