Would it be possible to print the torques of the terminals on the Victron Products?

There are some places where I would find it handy to print them out (for example):

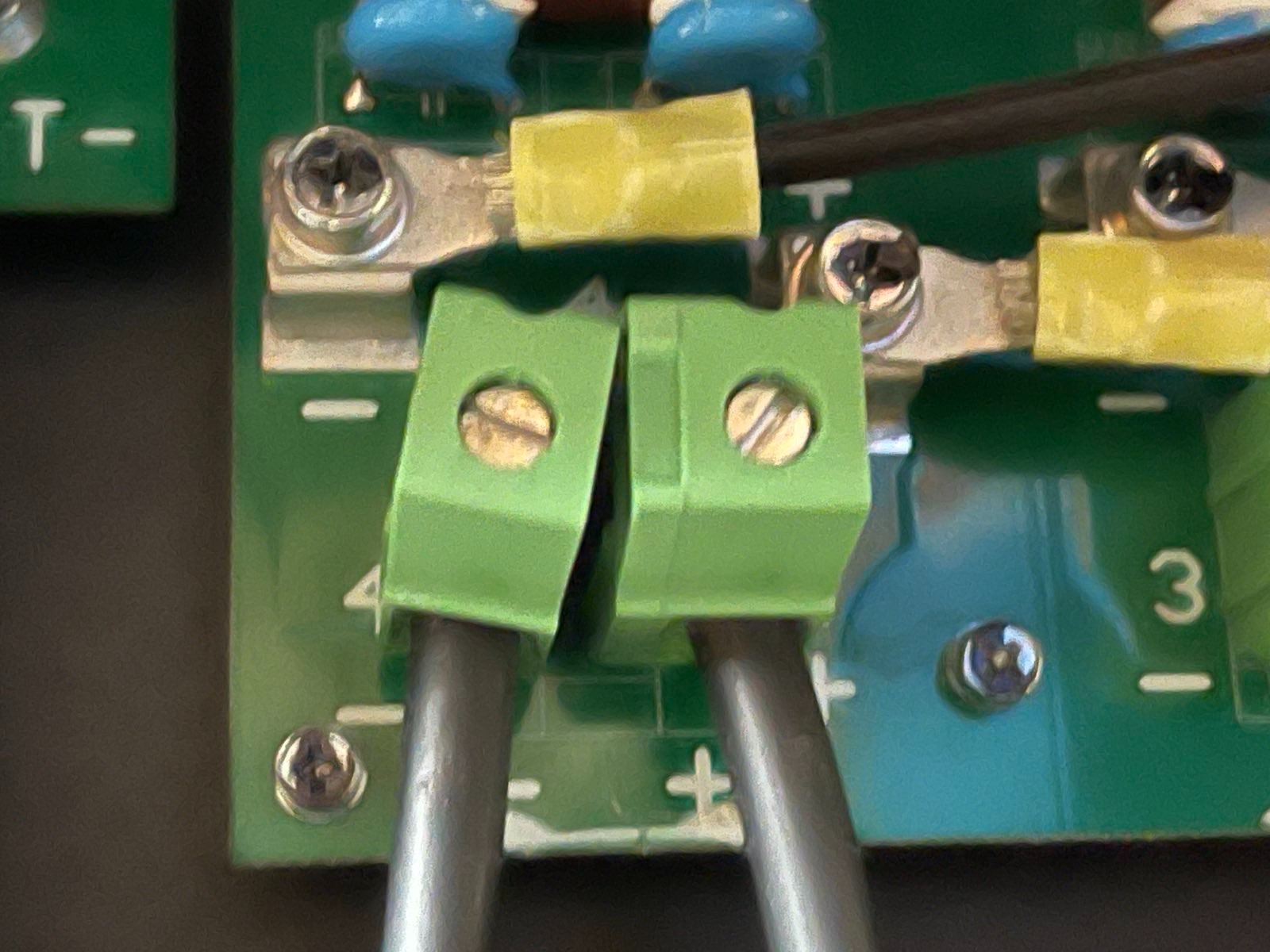

- Multi Plus / MPPT RS: on the PCB next to the therminal / bolt, or in the cover next to the schematic.

- Smart Shunt: next to the top printing (Battery minus / Load minus), or on the lable

- Lynx Distributor: under the Victron laser marking on the positive bolt holder.

That would be helpful. Especially since, for example, the torques of the M8 bolts of the RS450 (14 Nm) and MultiPlus (12 Nm) are different.

@Guy Stewart (Victron Community Manager)

Also, I can't find the torque of the PV terminals of the RS450 in the manual.