Hello!

Hello!

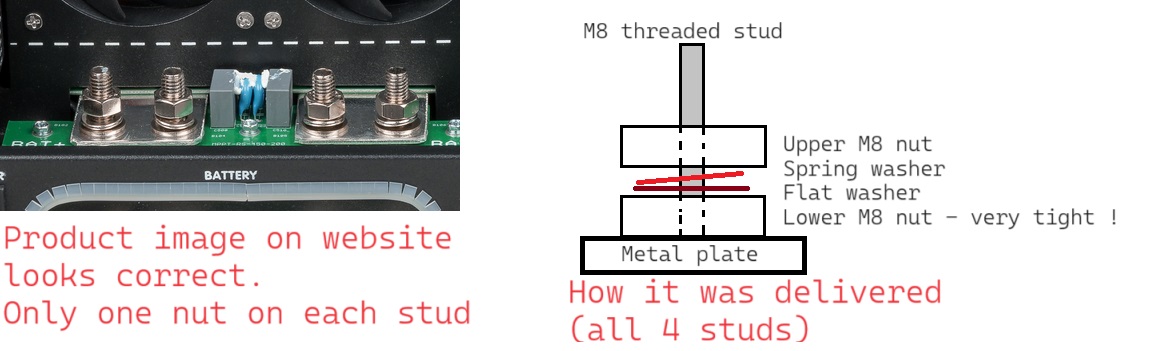

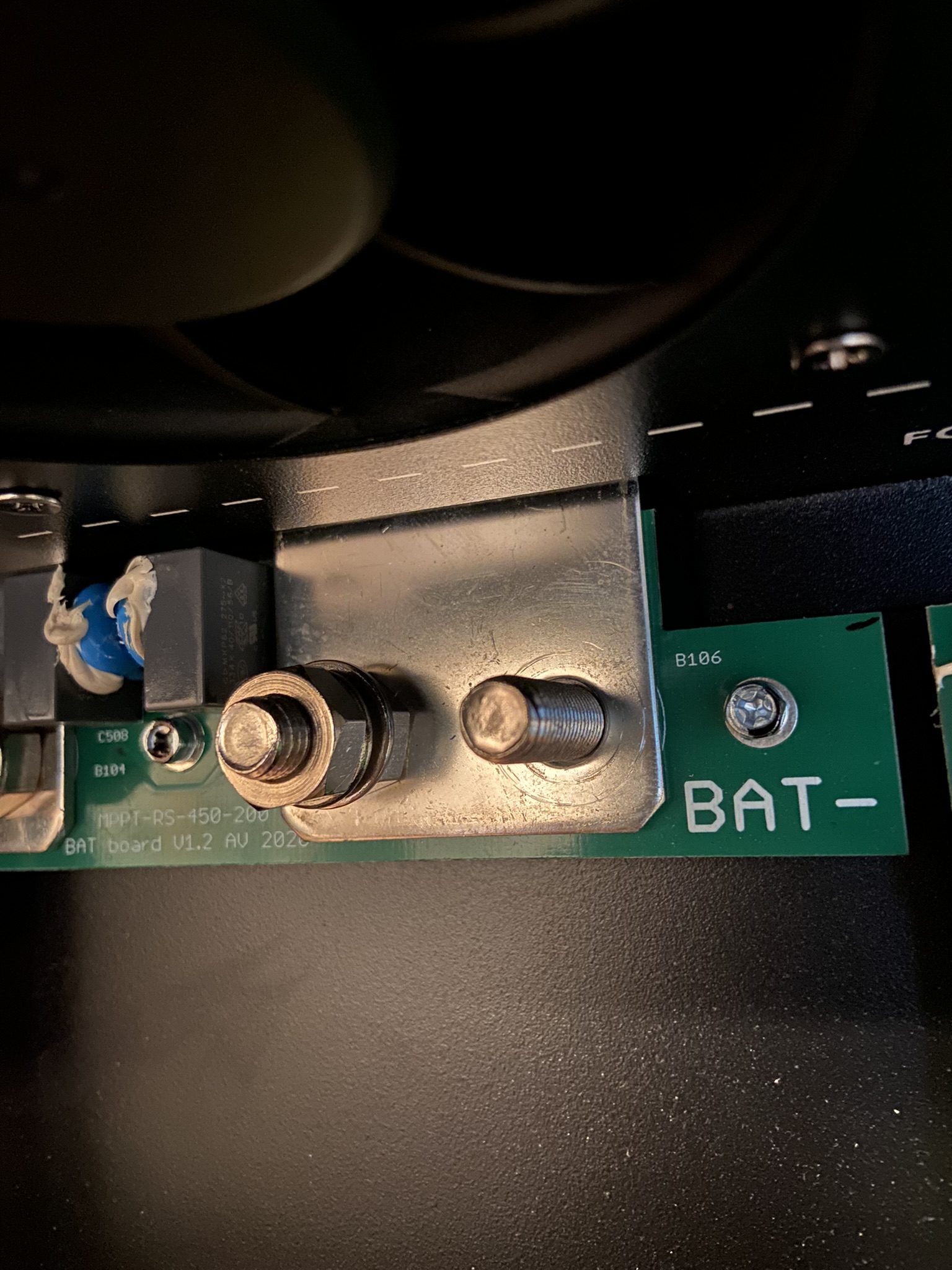

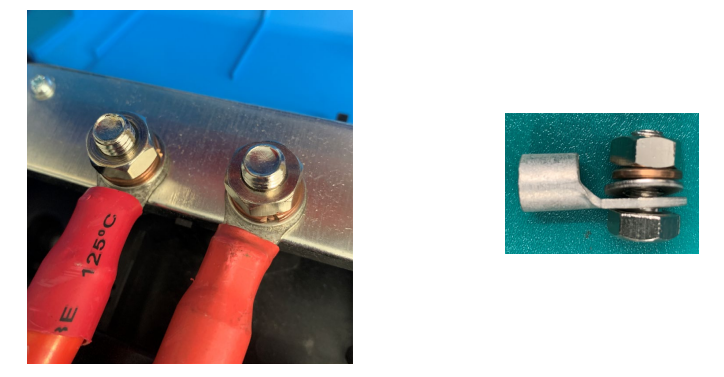

I can’t find instructions on the connection for battery/48V. The torque is specified to 14 Nm, but am I supposed to remove both nuts (as delivered the terminal bolt has nut-washer-spring washer-nut)?

Is the cable shoe supposed to be connected on top of the first nut or directly on the terminal with two nuts?

Consult the wiring unlimited book for detailed information about wiring:

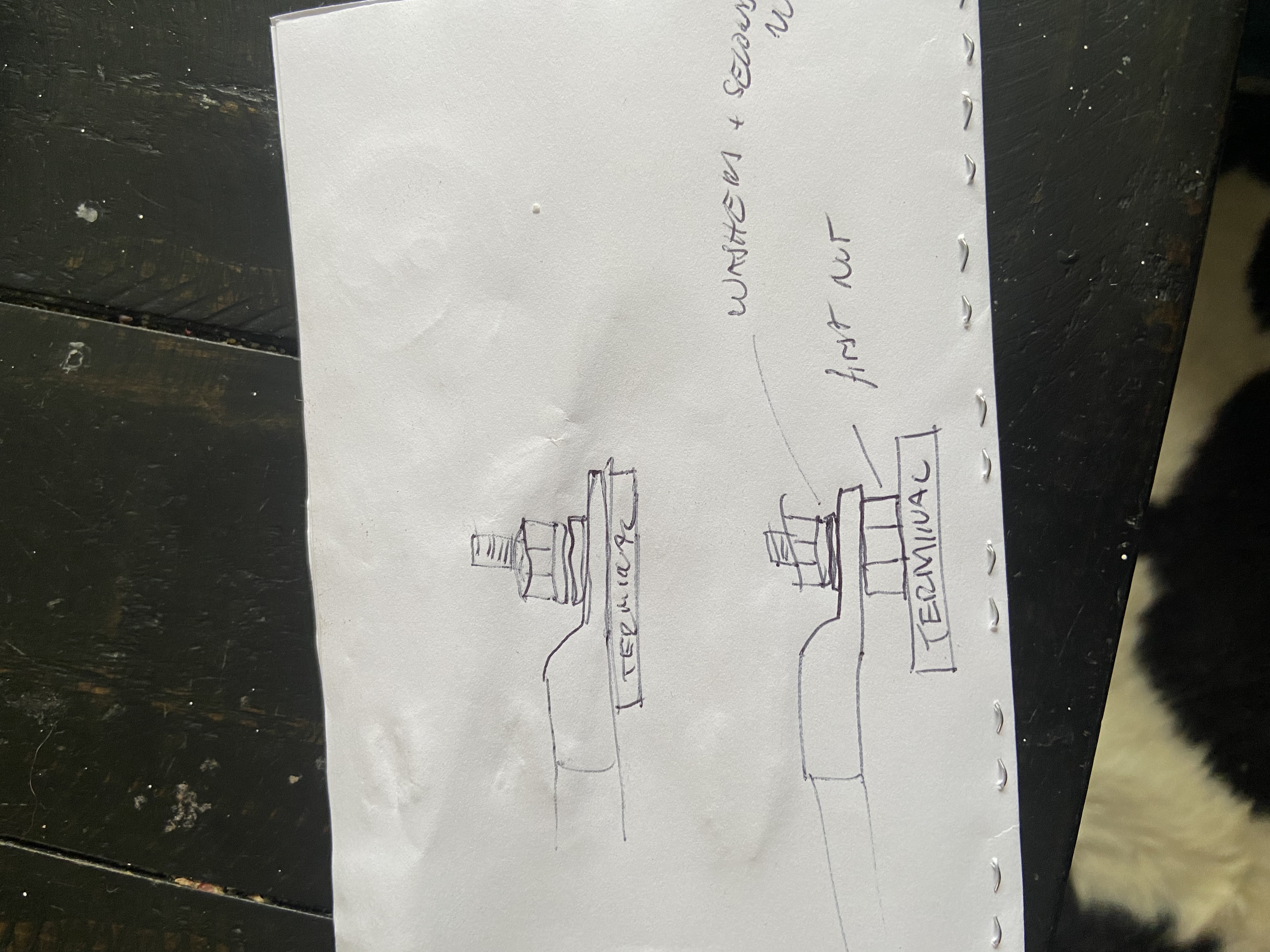

Consult the wiring unlimited book for detailed information about wiring: I’ll make a simple drawing!

I’ll make a simple drawing!