Hello!

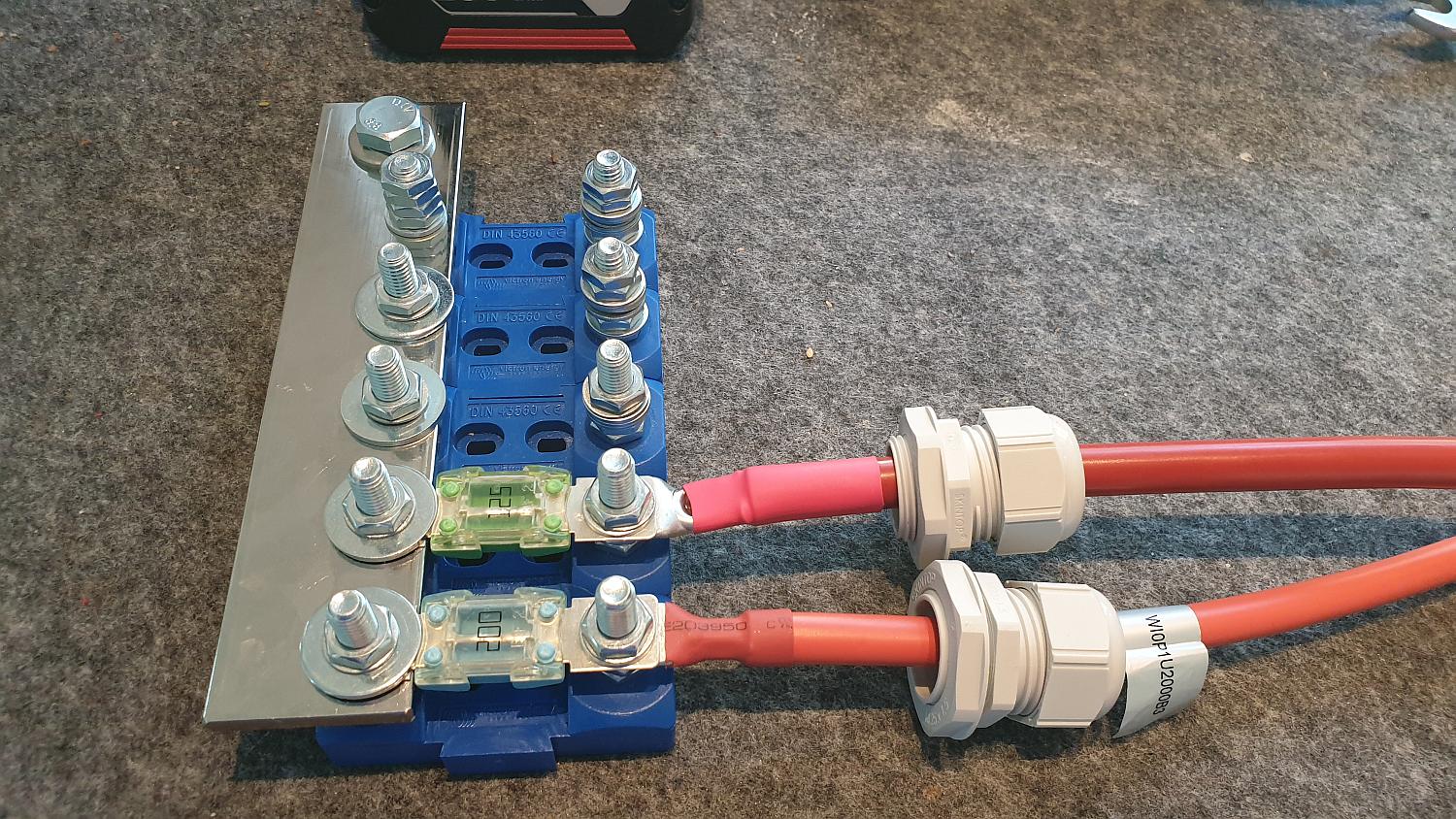

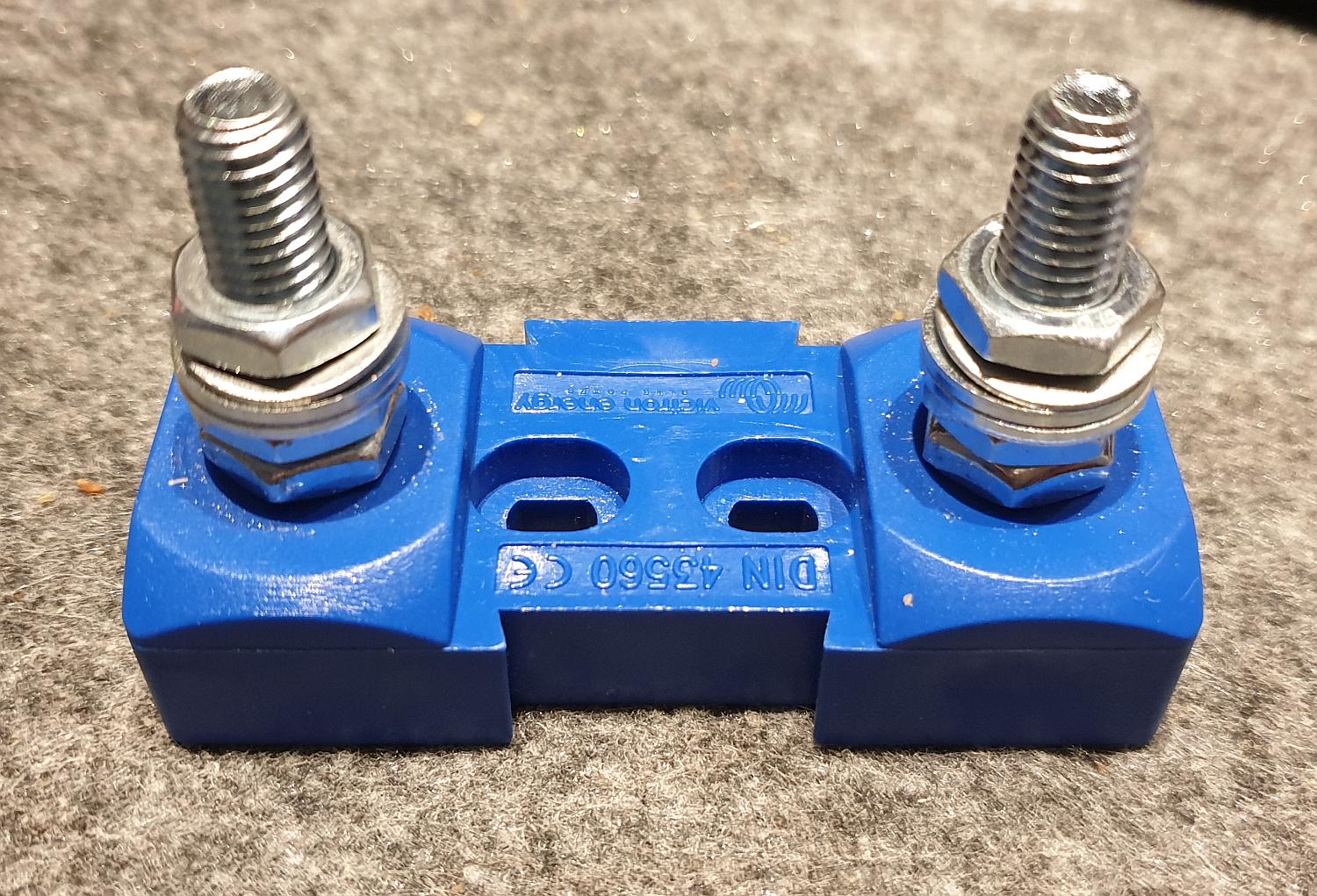

I worked today the first time with the Victron stacked fuse holder and the bus bar.

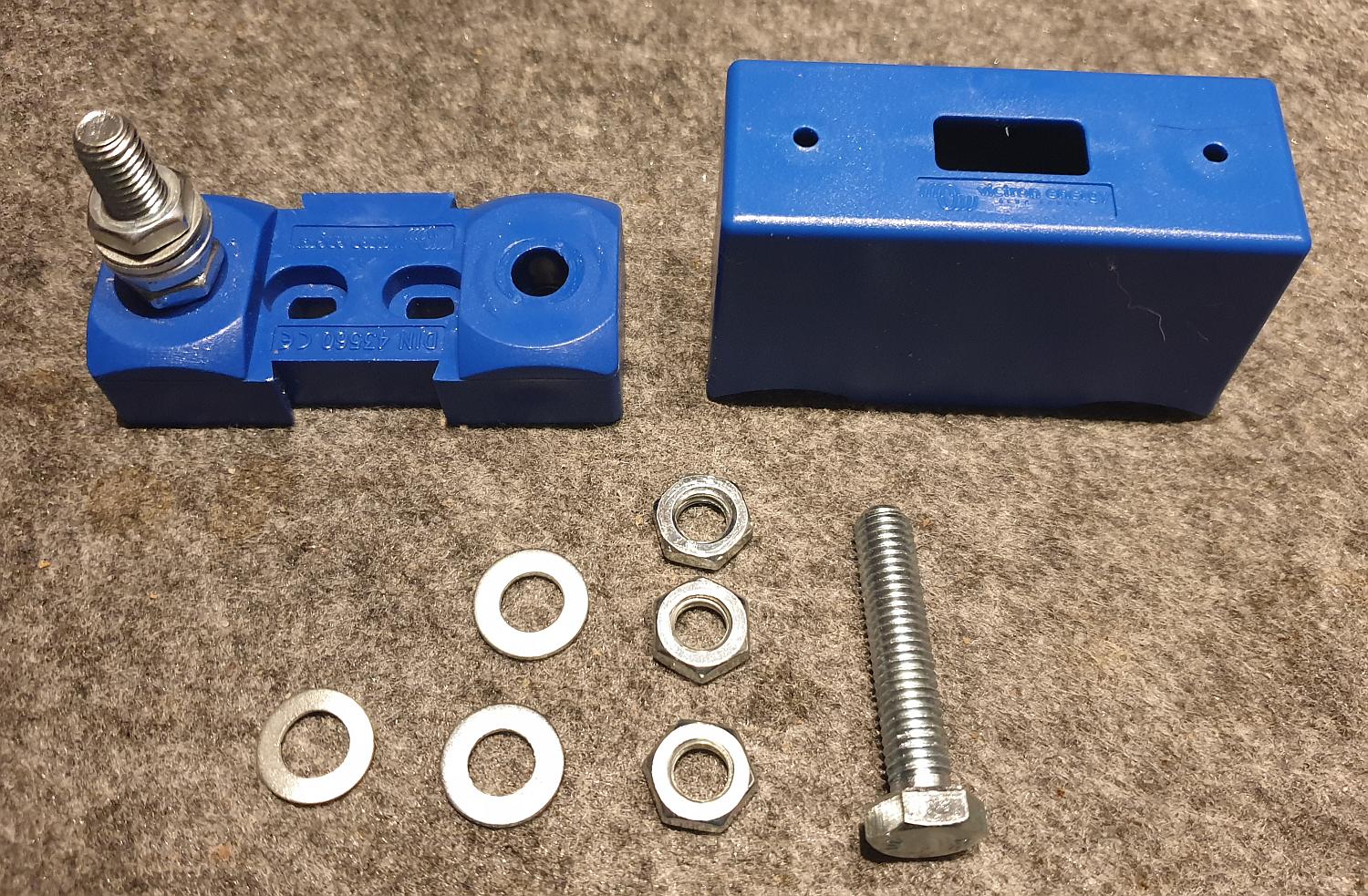

I am confused how to mount the stacked fuse holder with the Victron busbar. By dismounting one "screw stack" I got the screw M8, 1 pc. of wave washer, 2 pcs. of washer, 3 pcs. of nuts.

First question: Is it stupid to think the cable itself has to be fixed in a way that it can't accidentally jump off when changing a blown fuse?

Second question: Is how to mount the whole puzzle in combination with the fuse, cable lug and busbar?

To mount it as it can be seen on the Victron leaflet, seems to me at the first idea not correct, because than it is not possible to use the cover anyway.

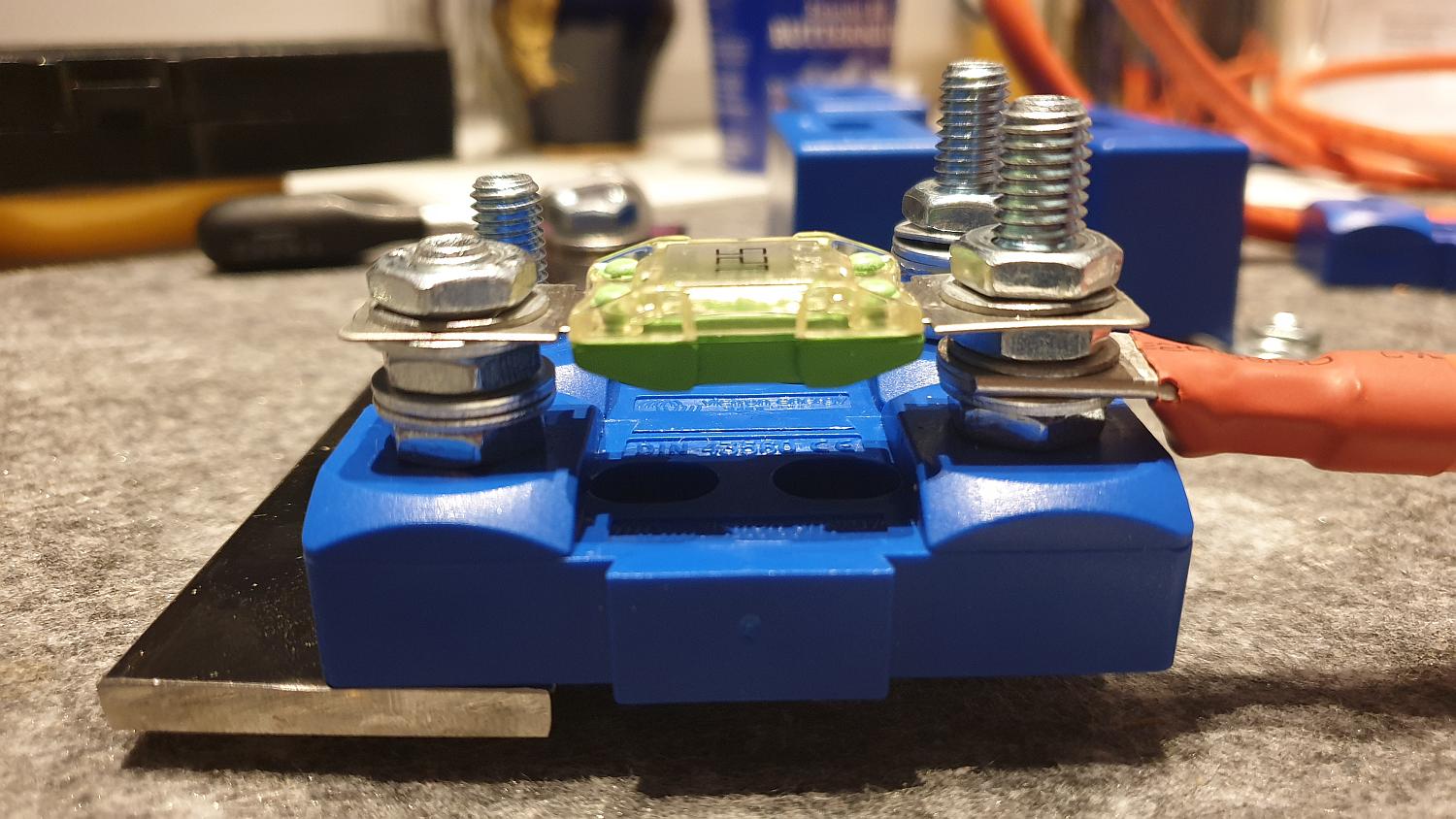

So I tried first to mount it on top of the busbar.

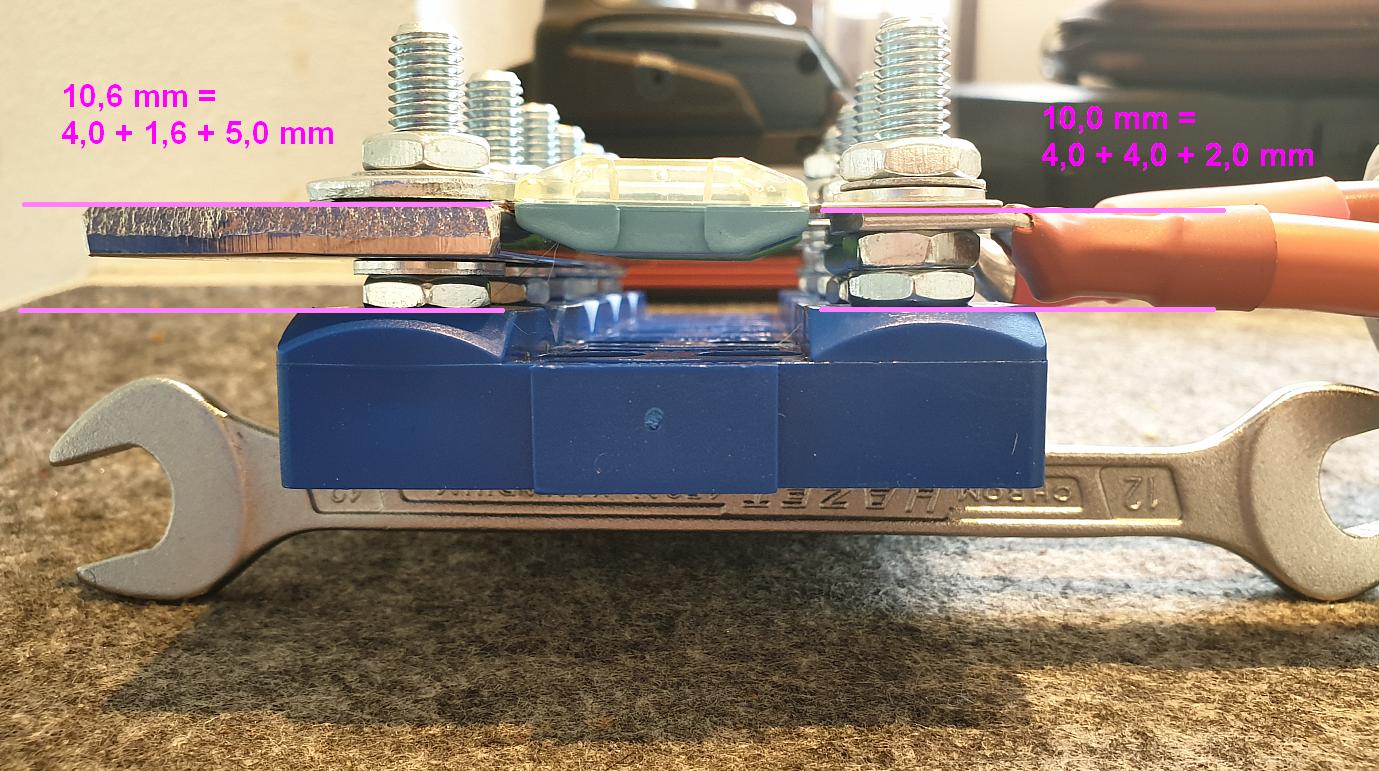

By doing so it is not possible to mount the fuse 100% horizontal, because the thickness of the washers, nuts, cable lugs are not equal so at the end the fuse is some how crooked. And I feel not sure if it is perfect in sense to get the most possible contact from the fuse to the screw - busbar - nut - cable lug. There is always as contact surface "only" a washer, which is somehow smaller as the fuse and smaller as the cable lug. And it looks with all the nuts, washers etc. in the best way of thinking strange.

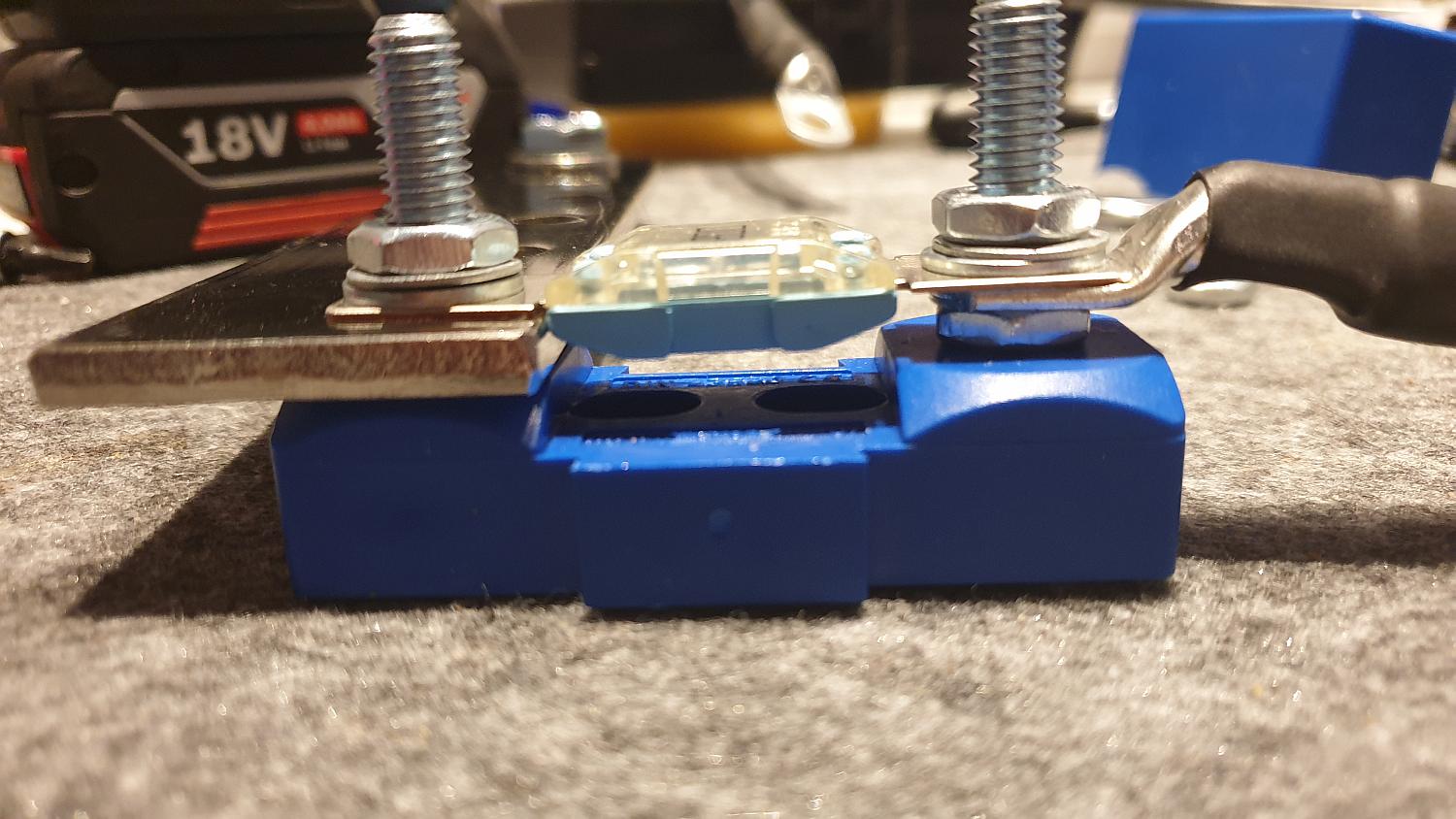

Therefore I tried the version to mount it under the busbar.

With this version it looks for me quit good. The fuse has a wide and 100% contact area from fuse to busbar and from fuse to cable lug. Still the fuse is somwhow crooked and not 100% horizontal. I don't care about this really. But I wonder there might be somehow some unwanted torsion onto the fuse, itself by this. Or doesn't this matter? And when dismounting the fuse when it is blown the cable lug is loose, too and it can "jump" off at an unattended moment and cause unwanted problems ... Is this the price you have to pay when wanted to get as much contact area as possible? And still I see no way to use the cover.

As I couldn't find any answers for my question at Victron, I hope to get some feedback here.

And last question. What maximum torque I should use to tighten the nuts?

I am looking forward for your ideas and thinking how to get the best and safest way of fixing all correctly together.

Kind regards and stay healthy

DayAndNight