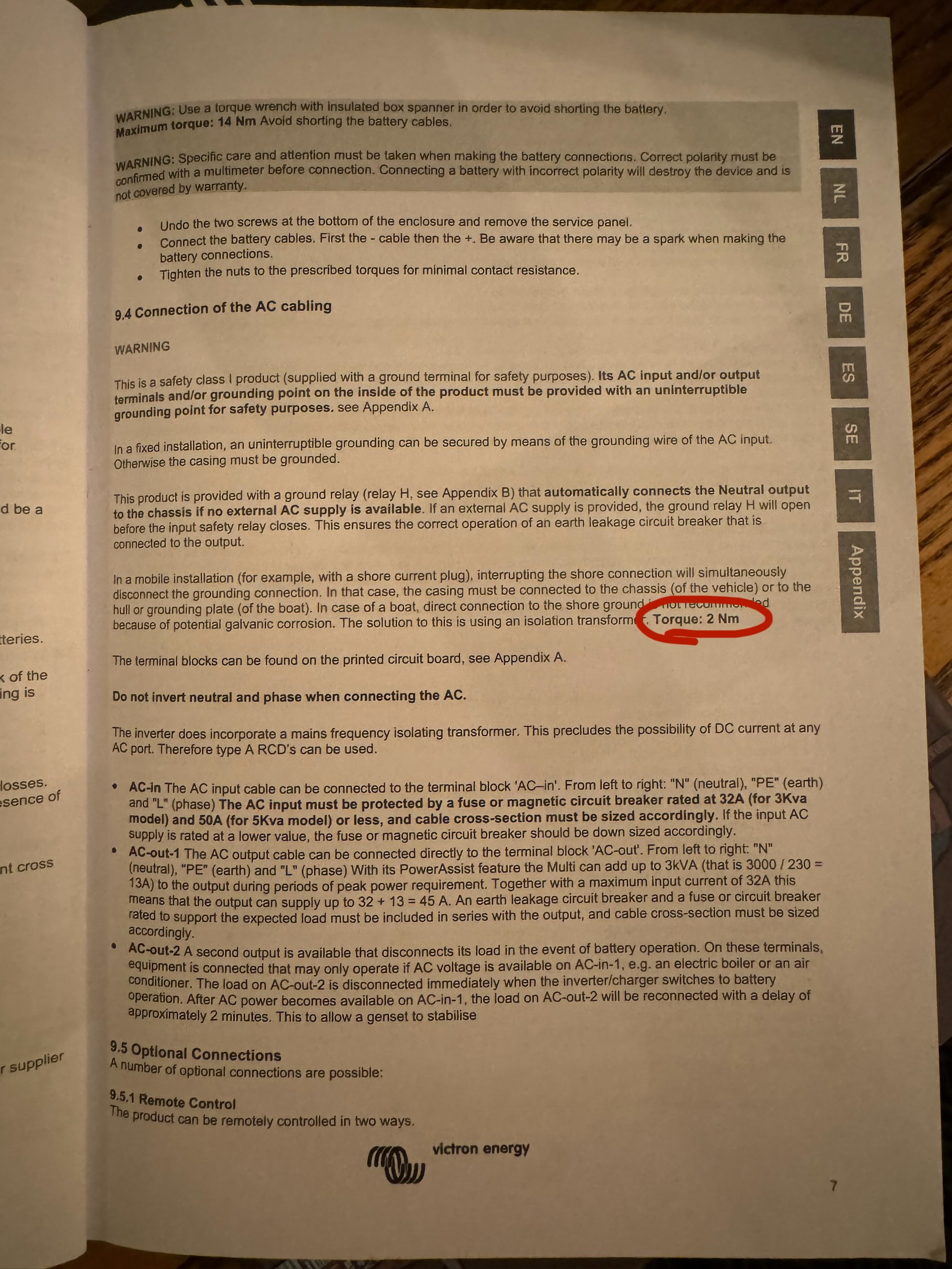

Are there any torque maximum or recommended values for the AC screw/clamp connectors on a Multiplus-II 5000? (Actually I have the GX version, but I presume it is the same hardware as the non-GX.)

The DC connections are specified — great stuff. But that AC connections not.

I've seen 1.5 Nm mentioned, but this seems incredibly low. Can it really be correct?

There are a few posts already asking around this topic, but no definitive answers. So asking agin in case it bumps the stats.

FWIW, and to add information, it seems (in the UK) that some 45A cooker switches are recommending 2.5Nm. That seems a reasonable equivalent in terms of power, although typically they would be connecting cable with fewer strands. Unless I hear different, this is what I will gingerly use as an ideal.

Related posts: https://community.victronenergy.com/questions/165150/torque-specs-for-ac-connectors-multiplus-ii-10000.html, https://community.victronenergy.com/questions/228589/torque-of-the-clamps-screw-connections.html.