I know this question is bordering not relevant for Victron, but I may not be alone with this issue - and there are so many skilled techies here so I hope you can forgive me.

If I get this wrong I'm in for a very expensive detour on my camper build.

I have a Quattro 12/3000/120 which is going to be the heart of my offroad camper electrical.

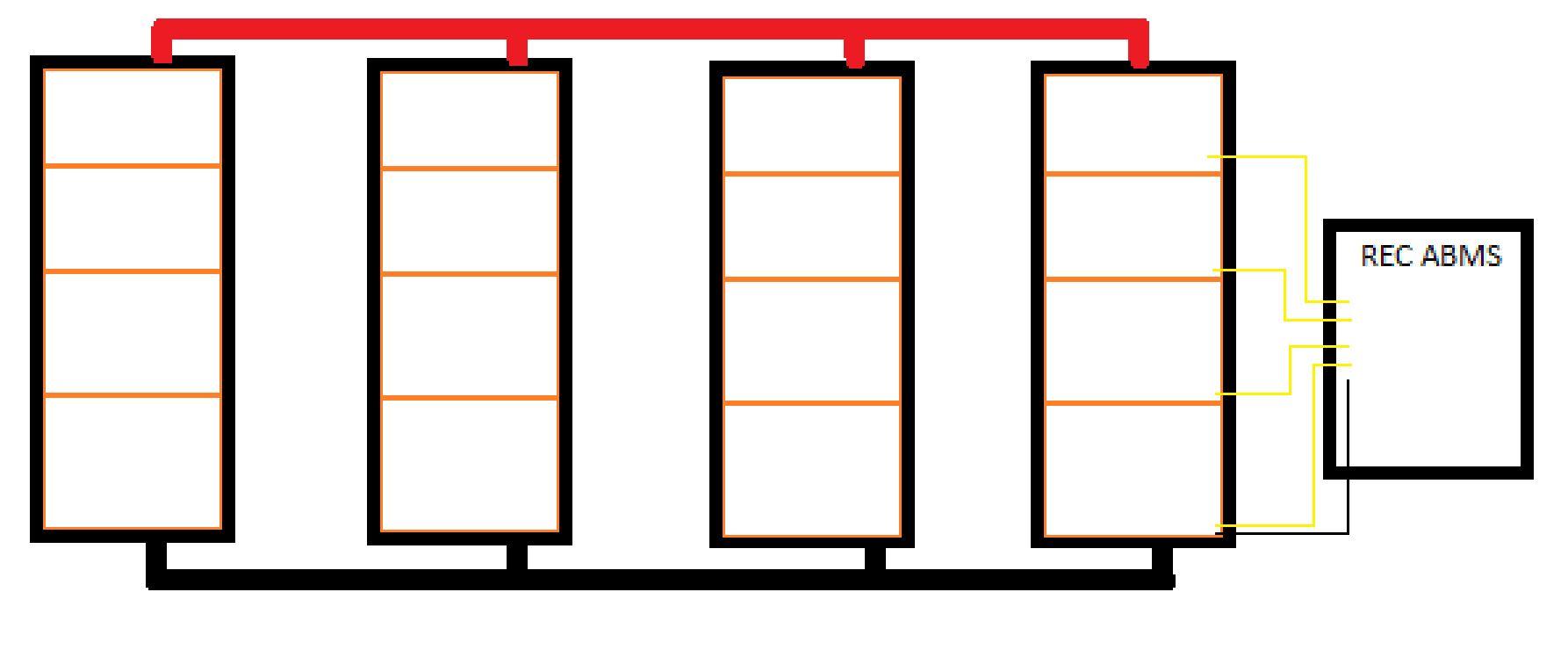

I purchased it because I want to use VW e-Golf Lithium Ion packs for my battery bank, and was recommended to purchase the REC 4S ABMS as it is compatible with the Quattro, supporting the required voltage.

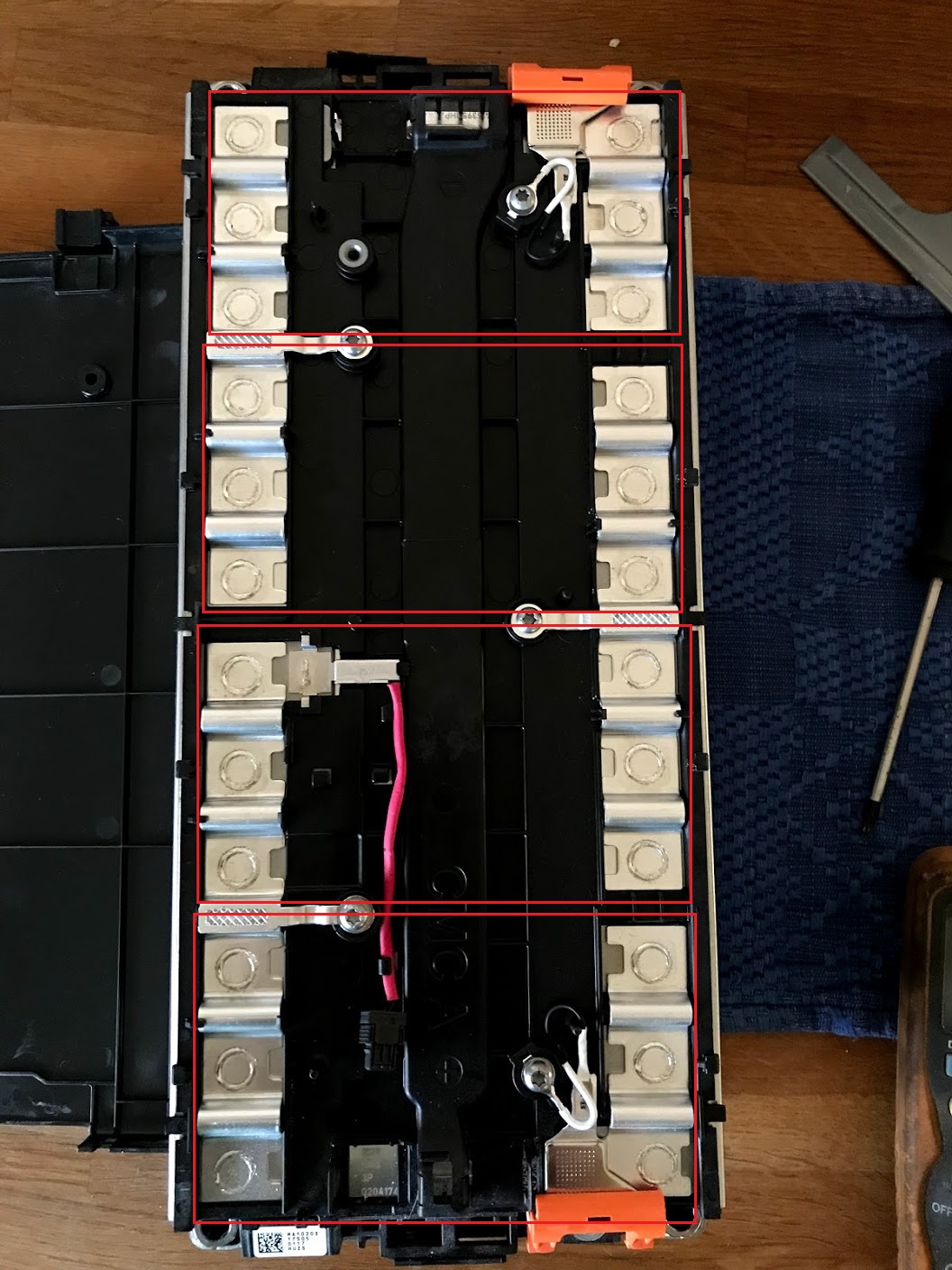

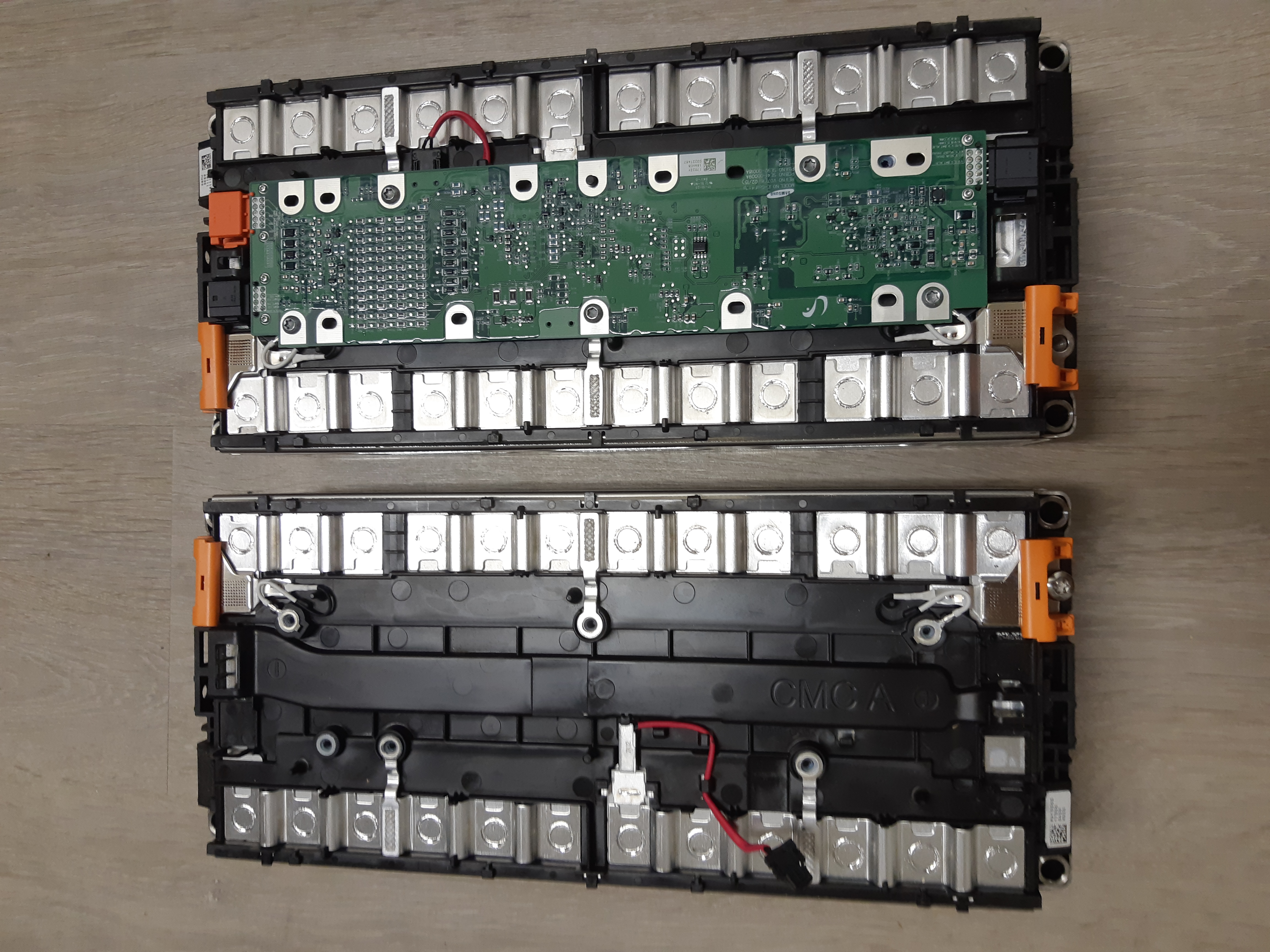

I want to build a bank around 10kWh capacity, and each VW module inside the VW battery is 4S3P, based on Samsung 37aH cells. I need 6 modules to reach the wanted capacity.

So far so good, but I fear I have an issue with battery bank composition and my expected result.

I purchased a couple of test modules the other day, and the guy says - sure - just connect the two modules in paralell, and connect the BMS to cells in one of the modules. He says the cells at the same parallell level will balance automatically across all 4S3P modules, and I will only need one BMS even if I add more of them. I'm in doubt though... since the 4S3P modules have no connection at cell level, how can they balance to the same level?

Attached are an image of one module from the VW e-Golf battery pack, and my 3rd grade level drawing of how I am supposed to connect this (according to the seller of the modules).

The individual 37aH cells are welded together and I suspect messing with that is going to cause more pain and cost more than I would like.

ANY advice is welcome at this stage.