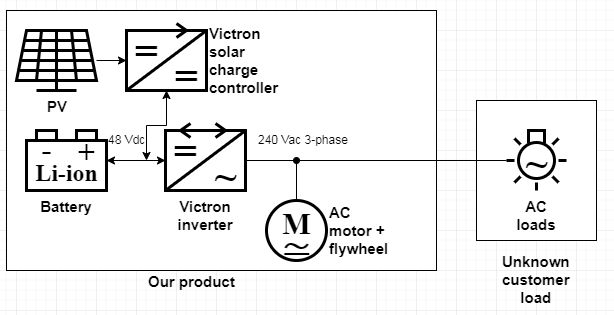

In our application, the load may pull short peaks of power that are 5 times the continuous rating of the Victron inverters. The inverters shut down momentarily, then recover. That cause flicker, which is undesirable.

Of course, we could stack up more inverters to power these short peaks.

But, we are exploring the alternative of adding a 3-phase motor and a flywheel to the 3-phase line to power these peaks and keep the inverters from flickering off and on.

Is that reasonable? Do you have any experience to share in this regard? Can you recommend an off-the-shelf product to do that? A "ride-through generator"? A "synchronous condenser"?

I looked at a flywheel UPS, but that includes high power inverters, and that defeats the goal of not having to add mode Victron Inverters to our system.

Thank you,

Davide