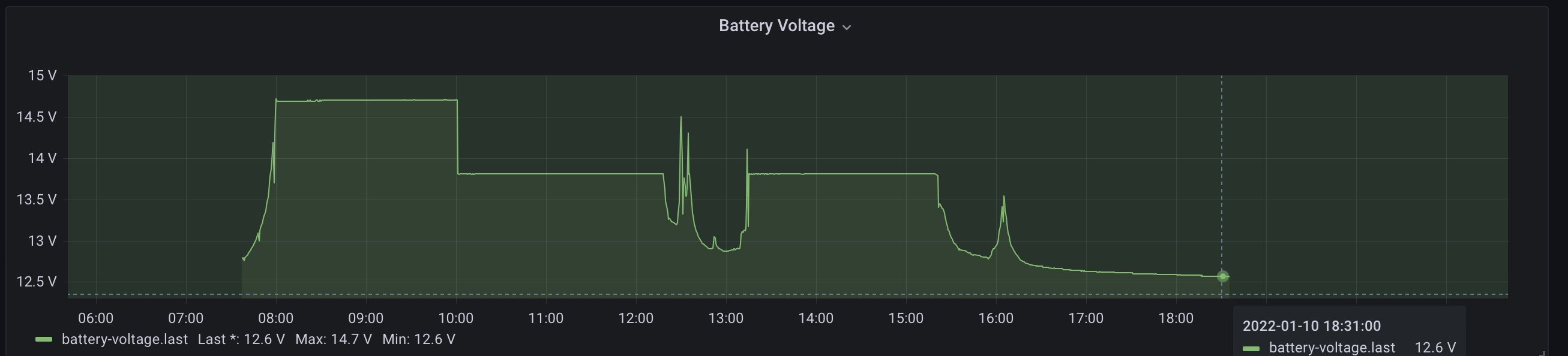

Update: Thanks to @snoobler, I now understand that you cannot trust the measured voltage of a battery system when it’s under load or being charged. Battery specs pertain to measuring voltage at rest. Once I understood this electricity 101 aspect, per the advice of @snoobler, I began to focus on the state of charge (SOC) data to help me home in on the measured voltage that equates to 50% SOC for my system. Once I home in on that value, I’ll be able to refine my charge controller configuration to avoid defer turning off the load terminals until that voltage is reached.

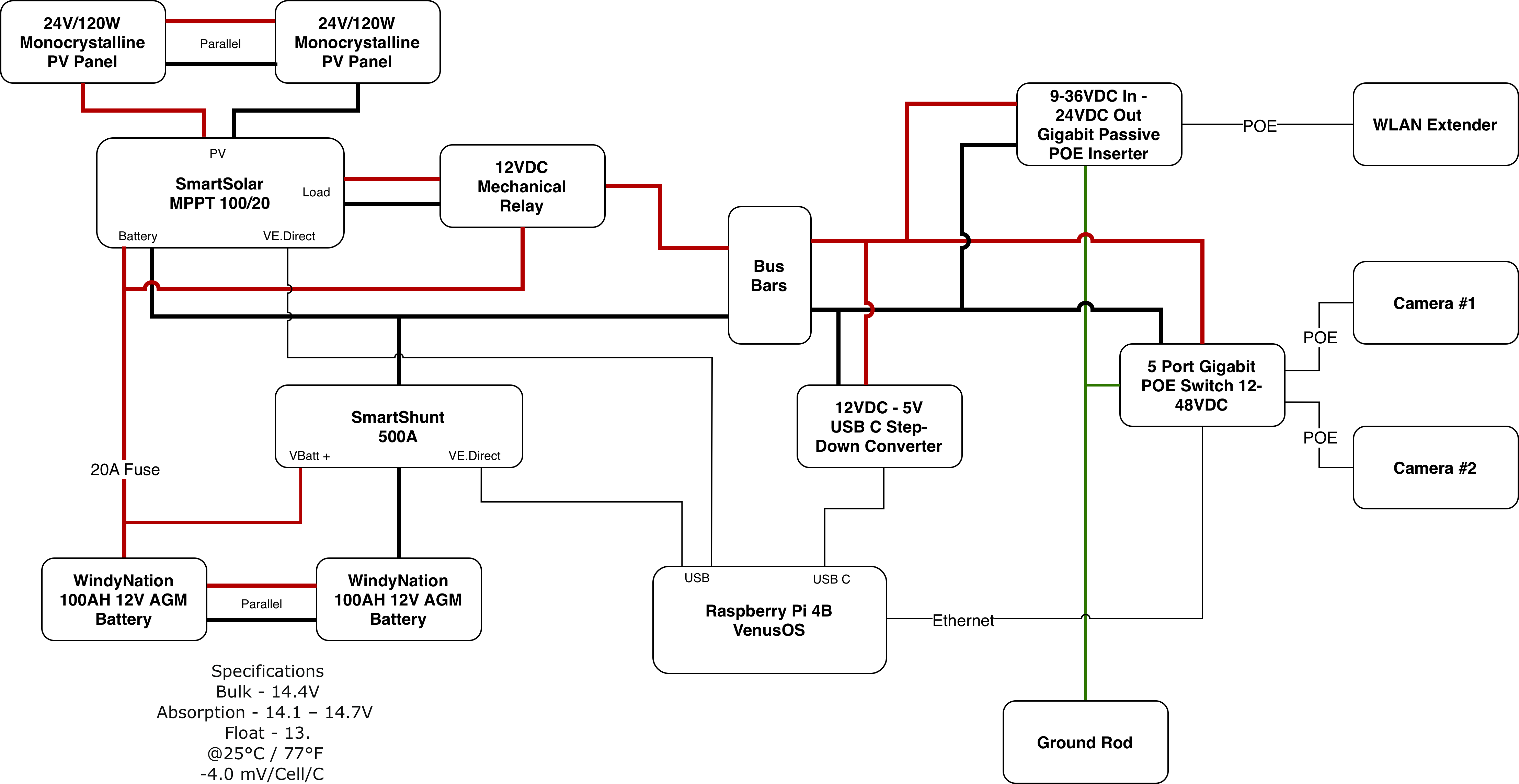

I installed a new outdoor pole mounted off-grid solar system of the configuration shown below in late November 2021. I am trying to determine if the battery performance I’m experiencing should be expected during colder winter months.

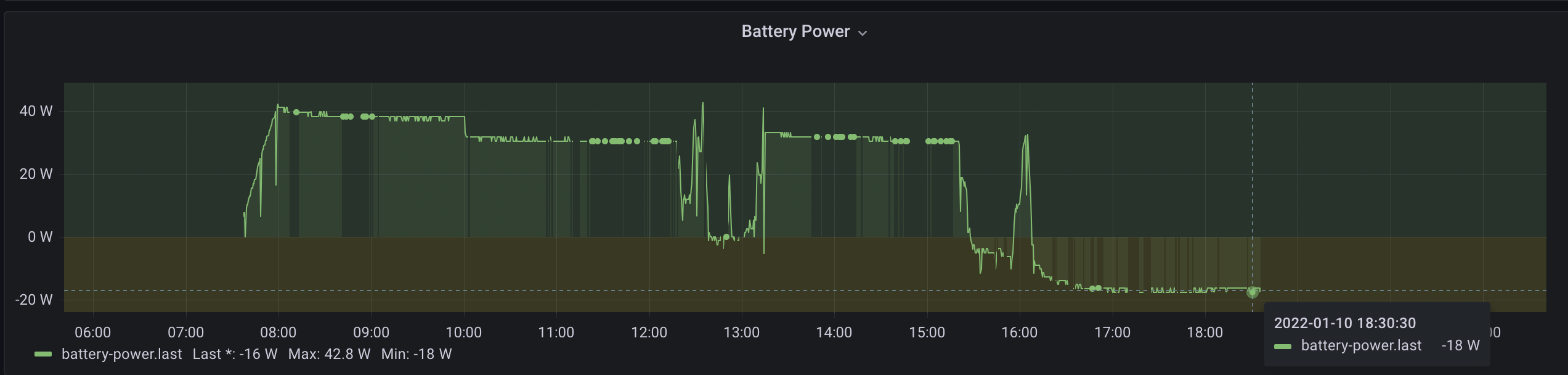

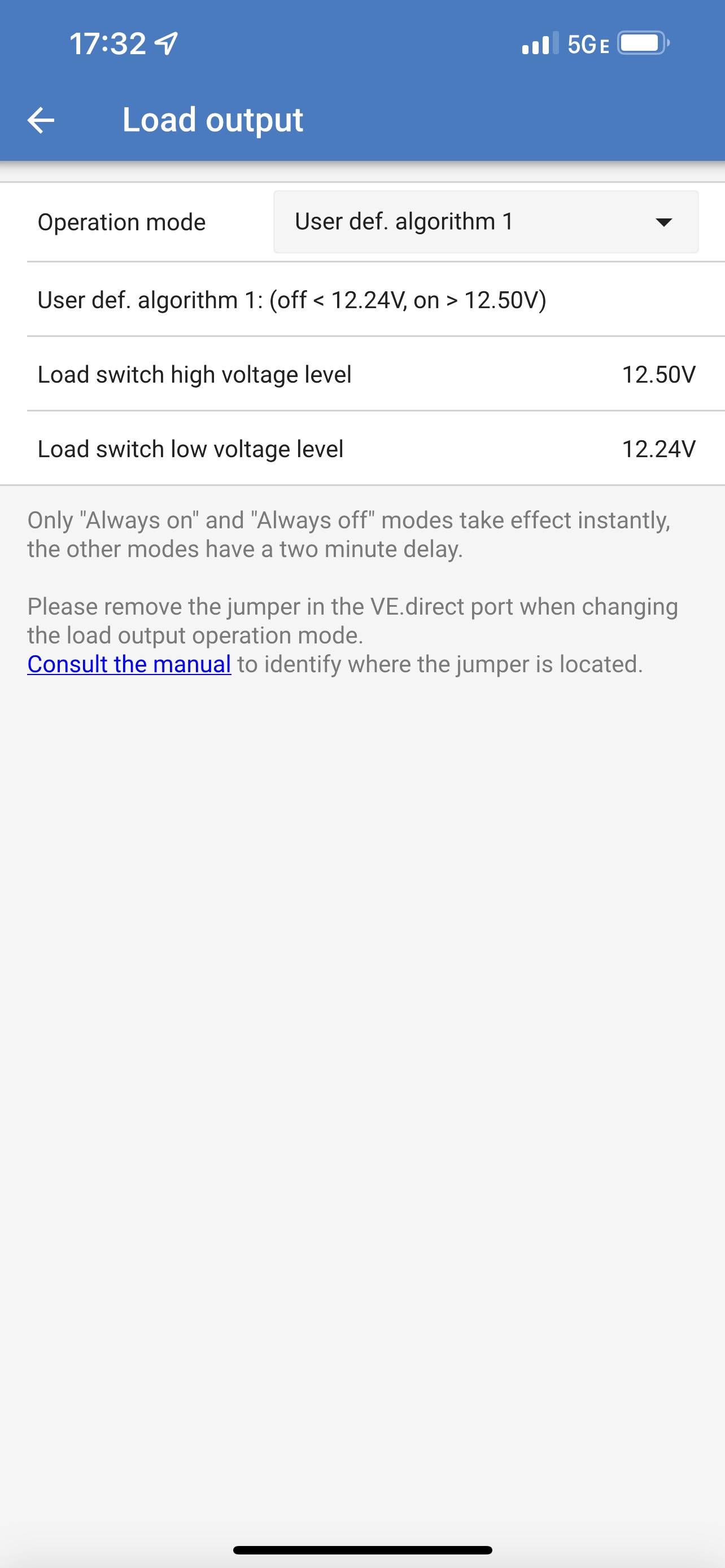

The 200Ah dual 12V AGM deep cycle parallel battery system appears to power the ~1.4A/18W 12VDC total load for only a few hours before the MPPT automatically shuts off the load via a 12V relay. The load is reliably switched off and on based on the Load output settings shown below.

Even in our variable winter temperatures, it seems that the battery system should be able to power the load for more than just a few hours.

My goal is to enable this system to run for at least 2-3 days without solar charging.

Several Notes and Questions

- Over discharge damage? Prior to configuring the Load output settings as shown below, I had been using the BatteryLife setting. However, with that setting, the MPPT did not appear to shut off the load during low battery voltage situations. Before I made the switch to the Load output settings shown below, I had seen the battery voltage drop to ~11.6V. I hope I didn’t damage the batteries by discharging them to that extent.

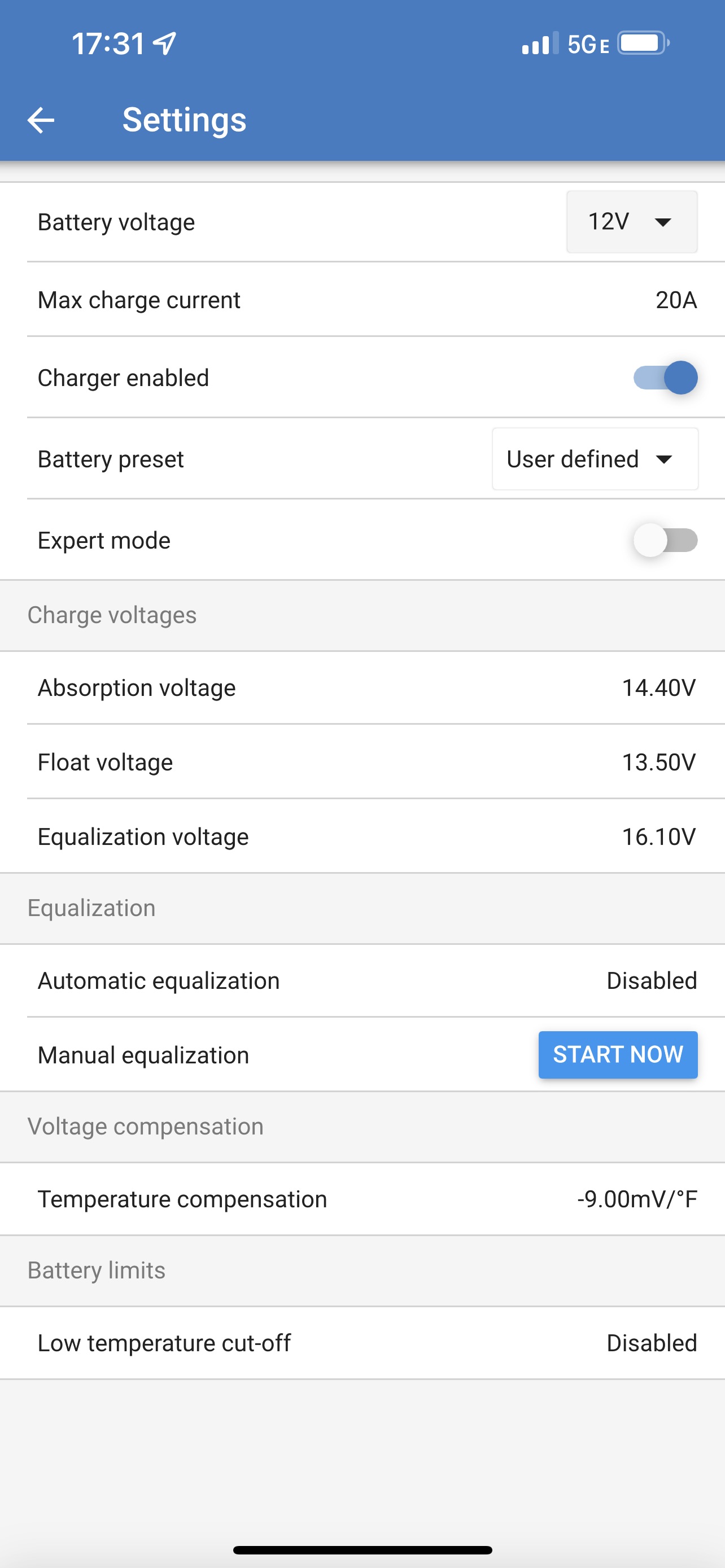

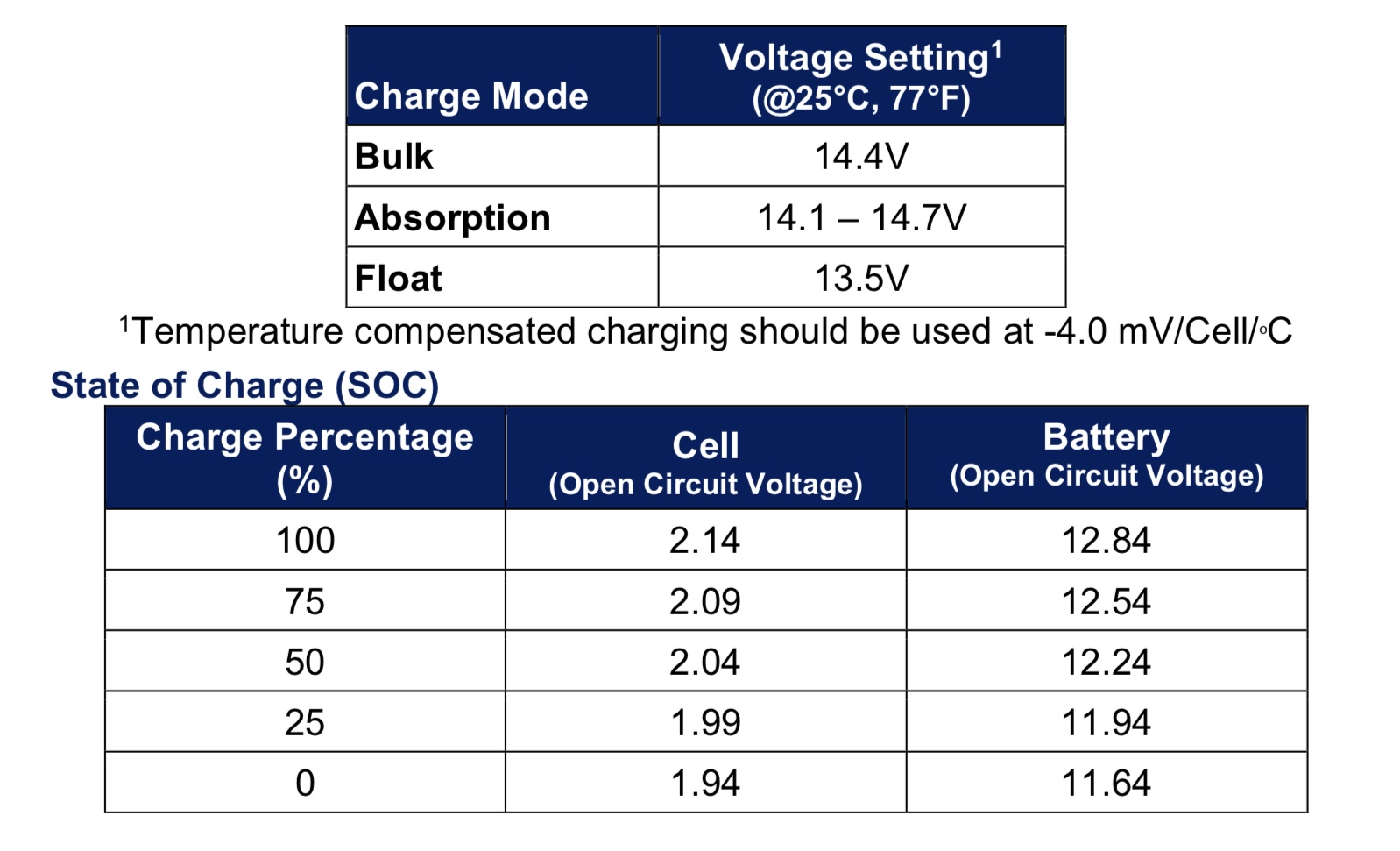

- Depth of discharge: Is 50% the right target for AGM deep cycle batteries? I’ve read conflicting advice. My current load switch low voltage is set to 12.24V or 50% DoD. If 80% DoD is reasonable, then I would adjust this setting to ~11.9V. However, I don’t see how that would dramatically alter the battery performance of the system.

- Potential battery damage due to charging in cold temperatures? We’ve had several sunny days during which the the outside temperature was in the mid-teens F. A few nights dropping into the low teens. It’s not clear to me if the AGM batteries could have frozen overnight and gotten damaged if attempting to charge them during the day. I do not yet have a battery temperature sensor attached via the SmartShunt, but am considering adding one so that I can configure the MPPT to avoid charging at low temperatures. I am not sure if the charging that has occurred to date during low temperature days. We’ve seen several days in the ~20F or so since I installed the system with lower overnight temperatures.

- Temperature compensation: It’s not clear to me how I should convert the -4 mV/Cell/C as specified in the battery specs in the diagram below to the F unit that is apparently needed in the MPPT settings.

- Translating battery spec absorption range: I used 14.4 as the rough midpoint of the battery spec’s 14.1-14.7V absorption number. Does that sound reasonable?

- Purpose of bulk value in battery spec? How, if at all, should I factor the batter spec’s Bulk number into the MPPT configuration?

- Load switch high value: I currently set this at 12.5V or roughly 75% SOC. Is this a reasonable setting?

- Switch to lithium? 100ah? Perhaps 24V? I’d hate to have to switch out these new AGM batteries, but if that’s what’s necessary, then so be it. If that comes to pass, would I be best served by going the lithium route? Since lithium can deal with deeper discharges, I’m wondering if 100ah 12V would suffice. Since most of the system components can support 24VDC (I’d swap out the relay and the 12VDC-USB C 5VDC down converter for 24VDC compatible units), I’m also wondering if I should make the switch to 24VDC battery system.

Recent Day

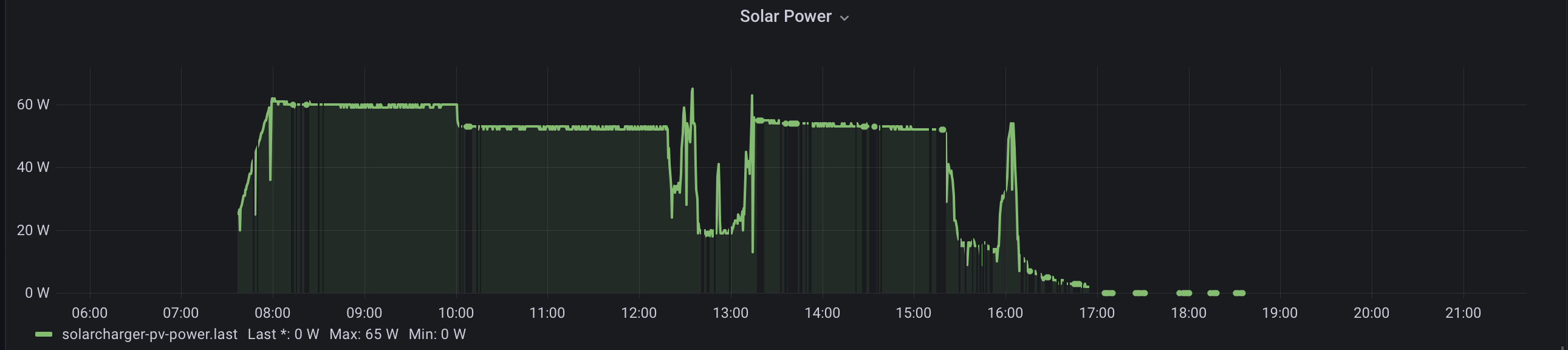

Mid-30sF day. Data captured via MQTT from the VenusOS-based Raspberry Pi.

…

…

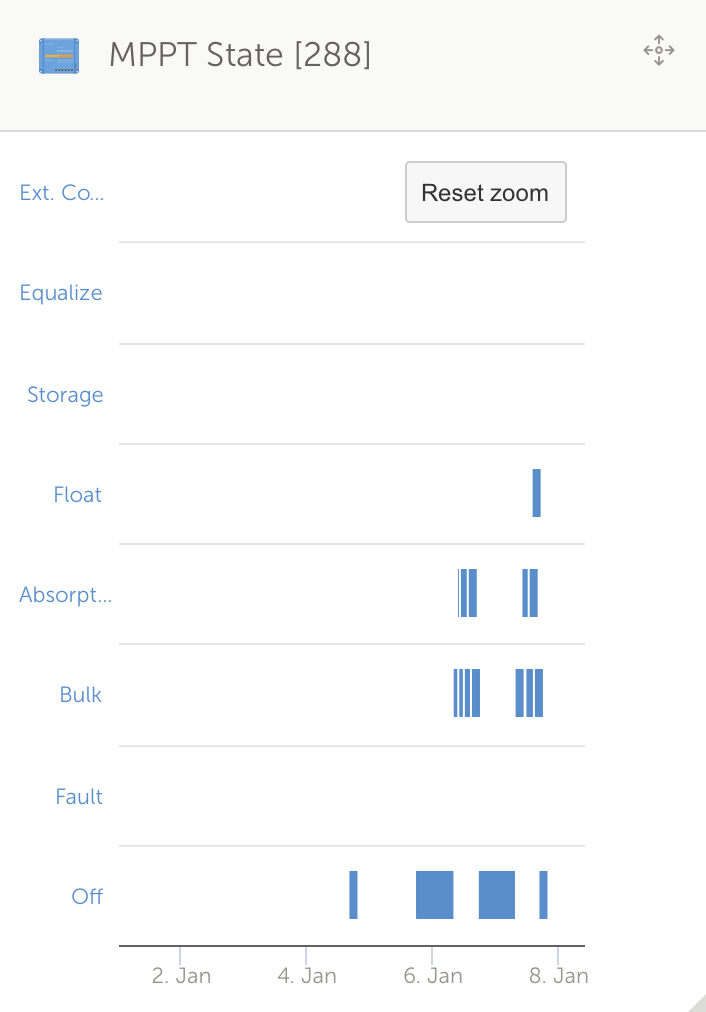

The fact that the system is entering bulk charging mode multiple times a day appears to point out a problem with the battery systems. I gather that with a properly sized and well operating battery system, bulk mode shouldn’t be needed more than once per day.

MPPT Settings

Battery Specs

System Overview