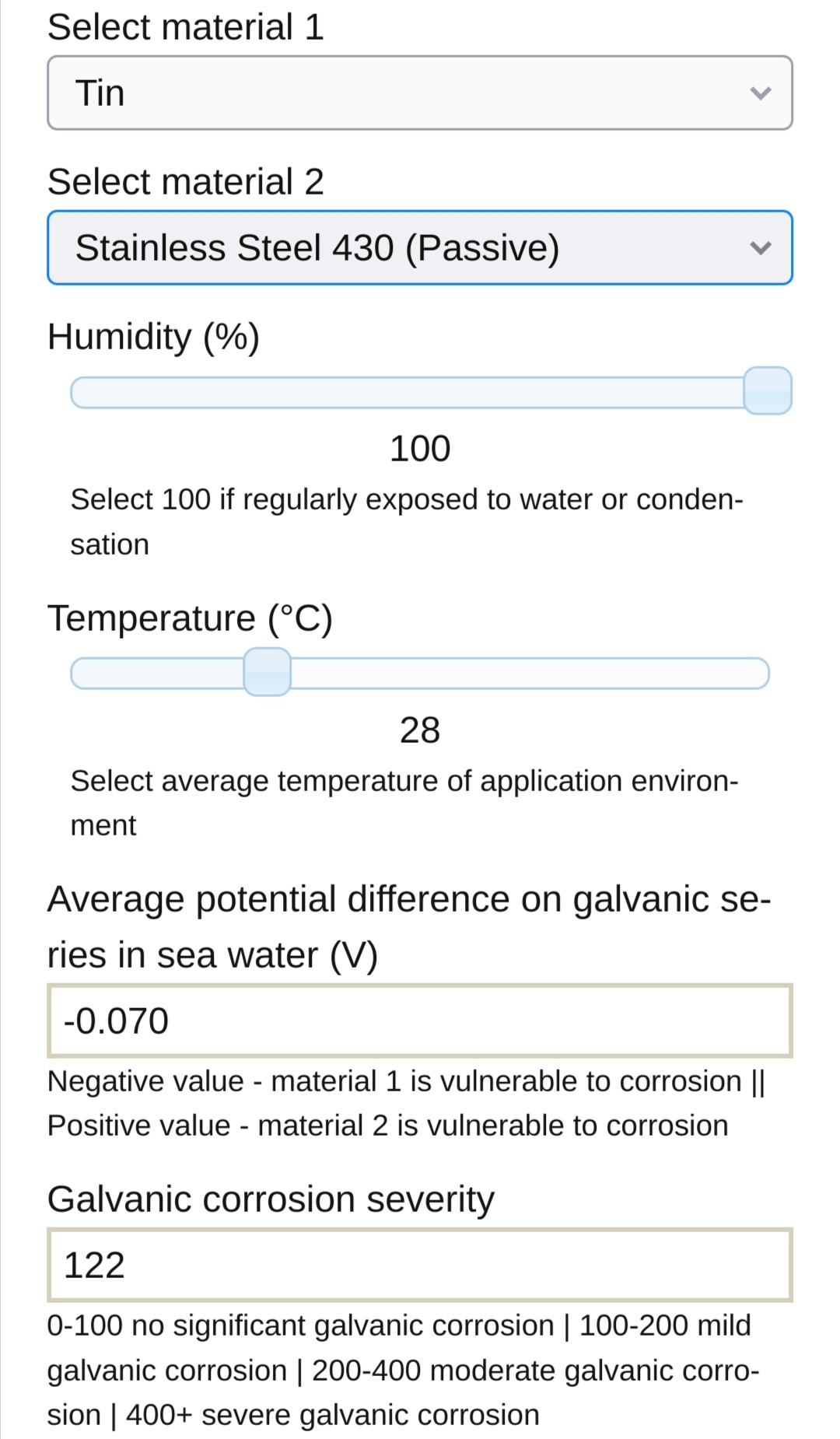

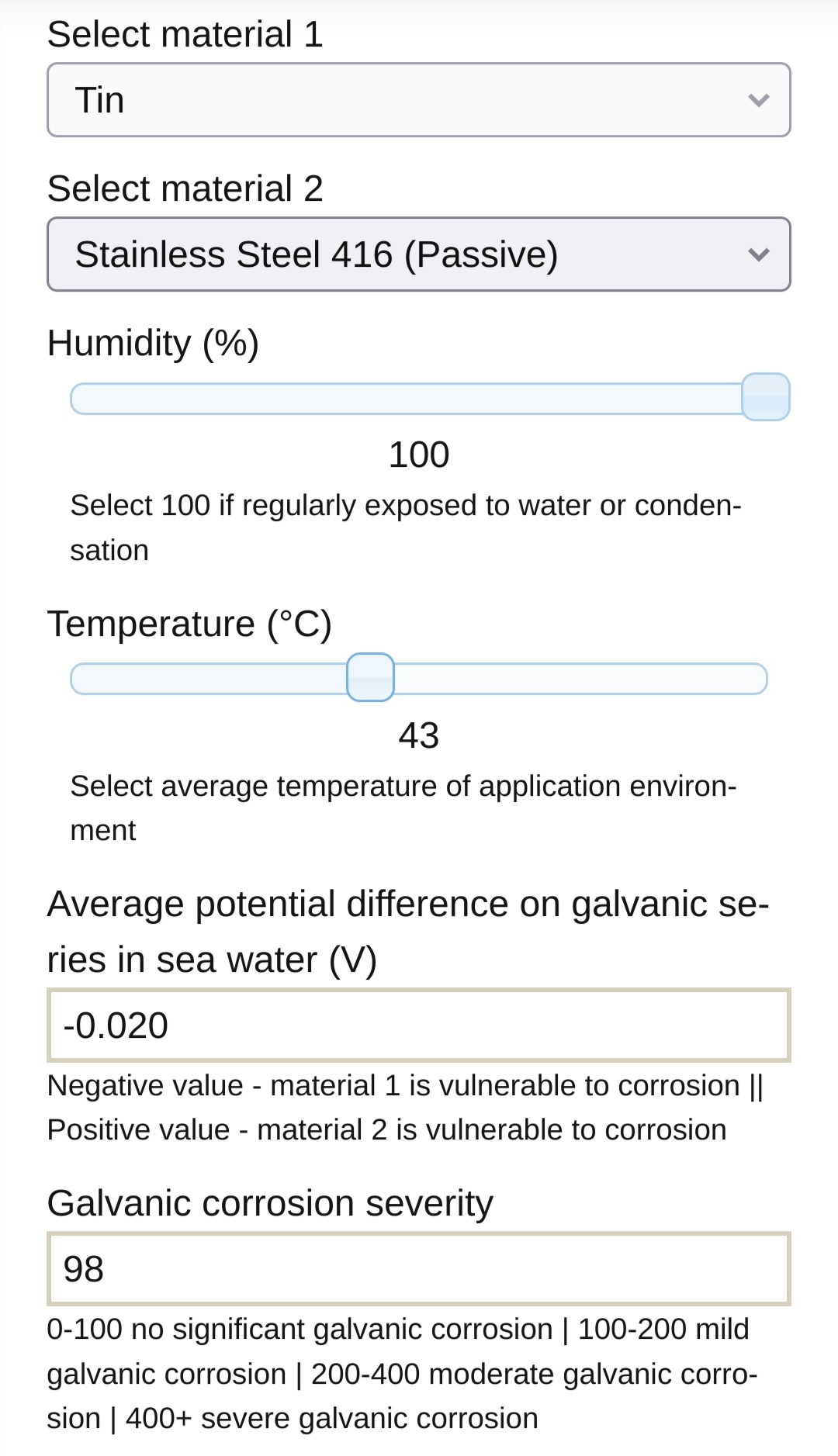

In environments with high humidity e.g. on a sailing vessel at sea we see a lot of corrosion at connections with metals with dissimilar potential.

In the presentation of the Victron fuse holders there is mentioned tinned copper bars with stainlesssteel (hope it is A4) bolts and nuts (rings)

These are materials with quite a different potential, isn't better to use tinned brass nuts bolts and rings.