Hi there,

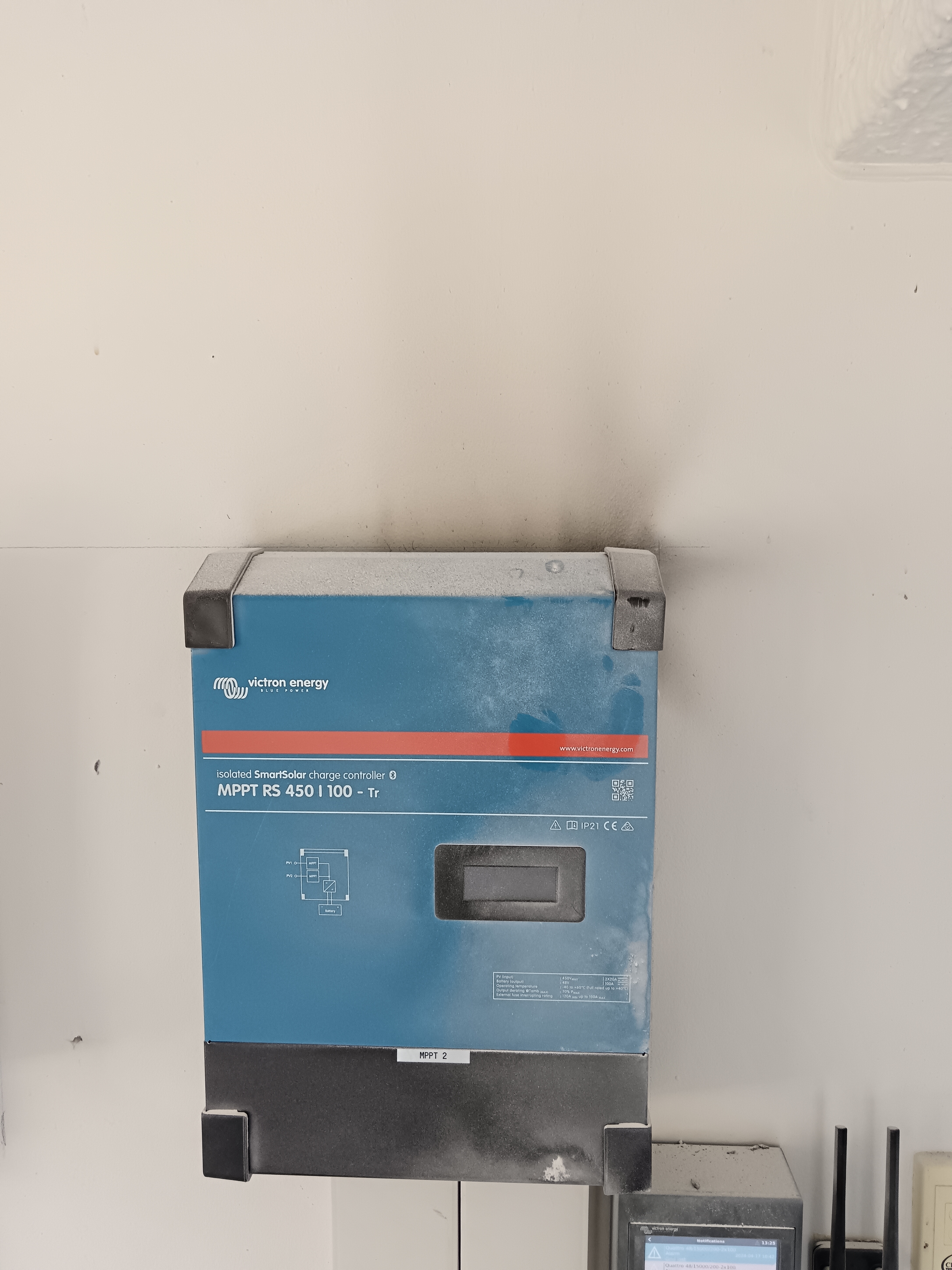

Installed a RS450/100 3 months ago. The unit charges 2x14.3kwH lithium batteries which feed a Multi II 48/5000. GX to control hardware/ESS. Sizing of the PV arrays was done using Victron's PV sheet/calculator, and all checked out.

- First Tracker runs with 8 x 605W Canadian CS7L-605MS (4840W)

- Second tracker with 6 x CS6W-545MS (3270W)

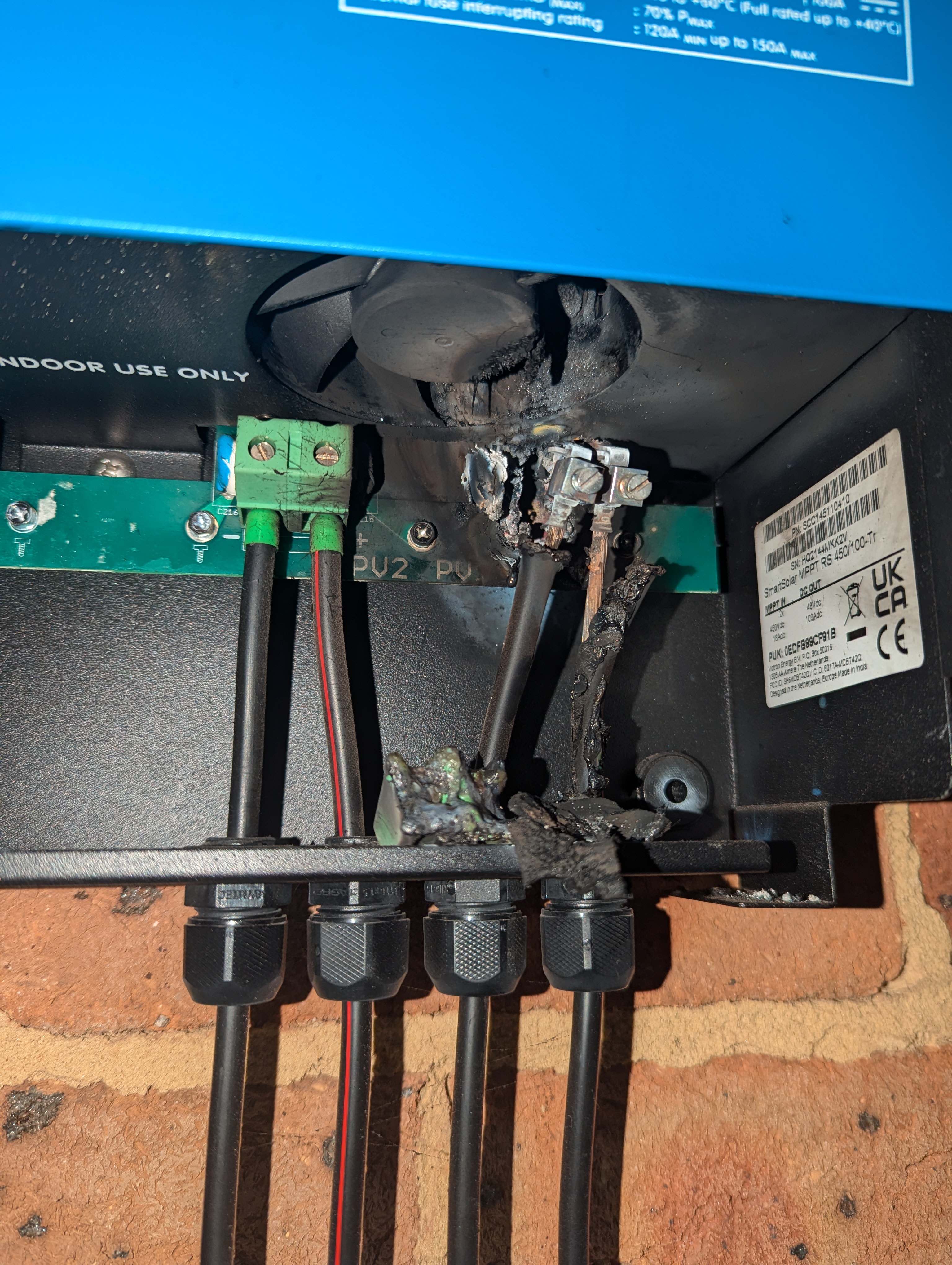

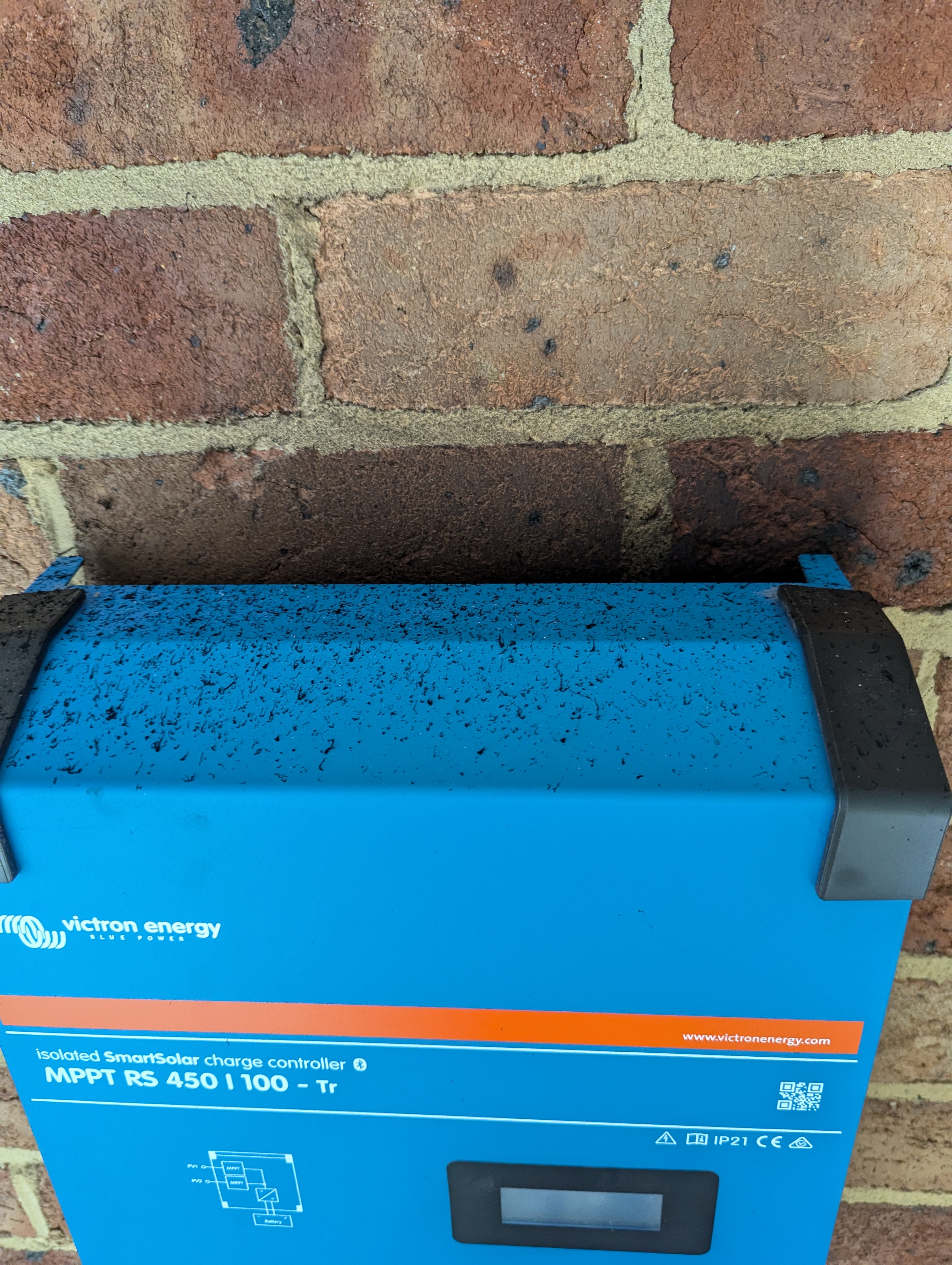

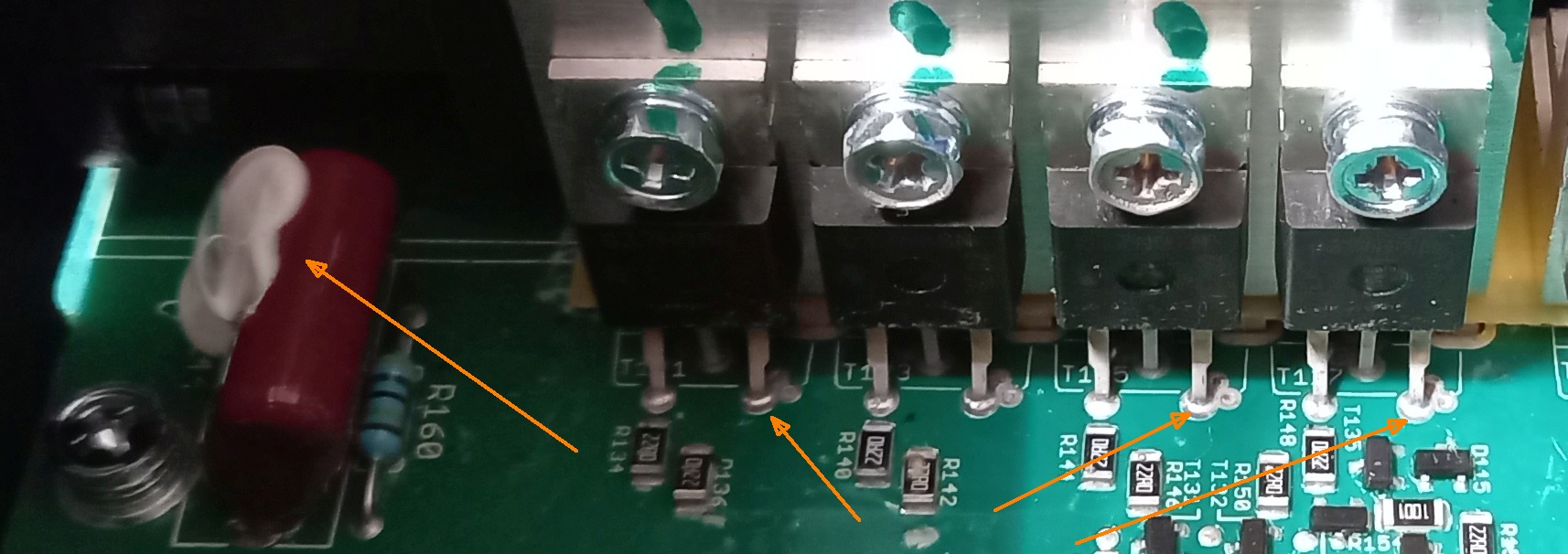

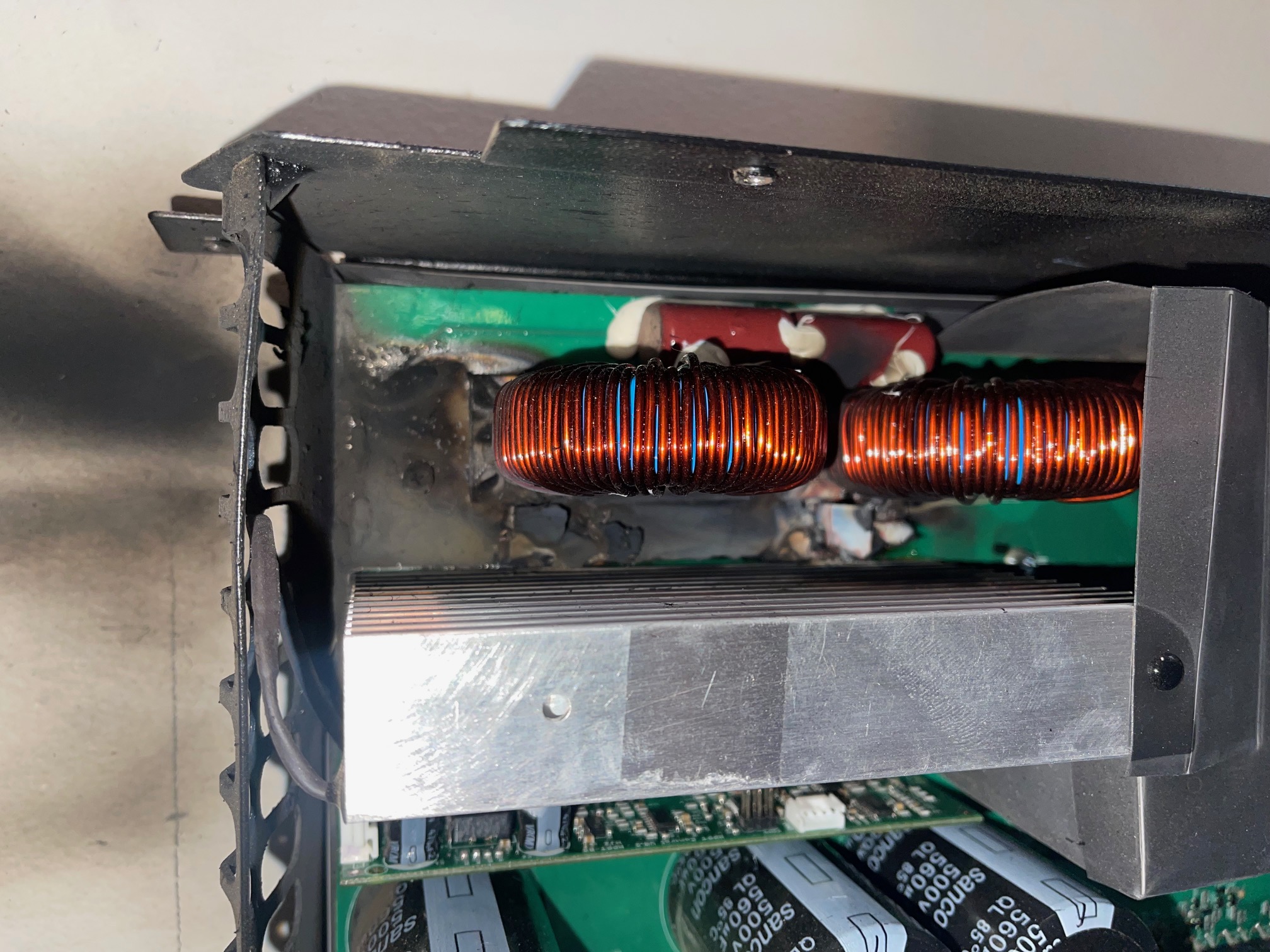

This past weekend the unit went up in smoke following (appears to be) some of the internal component failure. Fortunately no other damage or fire spread.

The maximum PV input voltage recorded on the unit to date is around 335-340V so well within the 450V nominal voltage,

I know that charge controllers normally fail due to poor terminations on the DC or PV terminals, but this is not the case here. Unit is in a well ventilated area, and it is winter at the moment, so the unit could not have been operating very hot.

I've actioned a warranty claim with my reseller, but I remain concerned as to why this could have happened in the first place.

Anything that I'm missing?

Thanks,

Nick

In the past 2 weeks I have had 2 RS450 /100 Mppts go up in smoke, so bad that in both cases a fire extinguisher had to be used. One installation is just on 2 years old and the other is just over a year old. The first one unfortunately was offline so I can't see the fault code, the second ones fault code is 201. Both systems have 8x 545watt JA Solar panels per string so the voltages (VOC) is under 400V. One has been returned and I did the RMA for the second one today. The one is HQ2138 the other is HQ2139.

In the past 2 weeks I have had 2 RS450 /100 Mppts go up in smoke, so bad that in both cases a fire extinguisher had to be used. One installation is just on 2 years old and the other is just over a year old. The first one unfortunately was offline so I can't see the fault code, the second ones fault code is 201. Both systems have 8x 545watt JA Solar panels per string so the voltages (VOC) is under 400V. One has been returned and I did the RMA for the second one today. The one is HQ2138 the other is HQ2139.

For record my RS 450/100 went up in smoke after 2 years of solid operation. The unit was still powered up when I got home with error #200 internal error. The fault occurred on sun rise. A lot of black residue covered the surrounding surface from the fault. My unit serial # is HQ2144.

For record my RS 450/100 went up in smoke after 2 years of solid operation. The unit was still powered up when I got home with error #200 internal error. The fault occurred on sun rise. A lot of black residue covered the surrounding surface from the fault. My unit serial # is HQ2144.