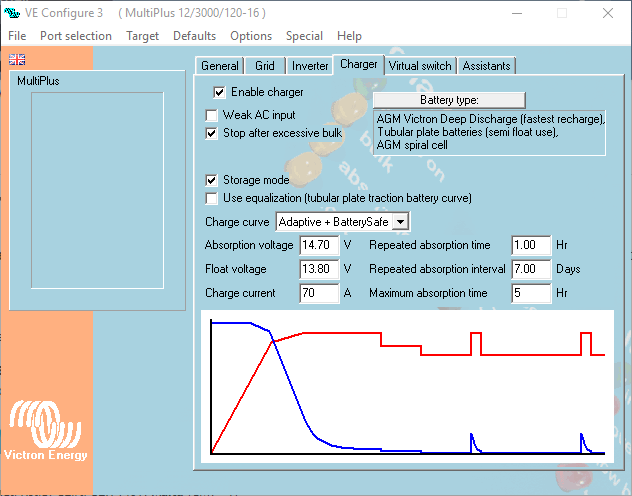

We had our system checked and the VE engineer set the ABS to 14.70 and the Float to 13.8.

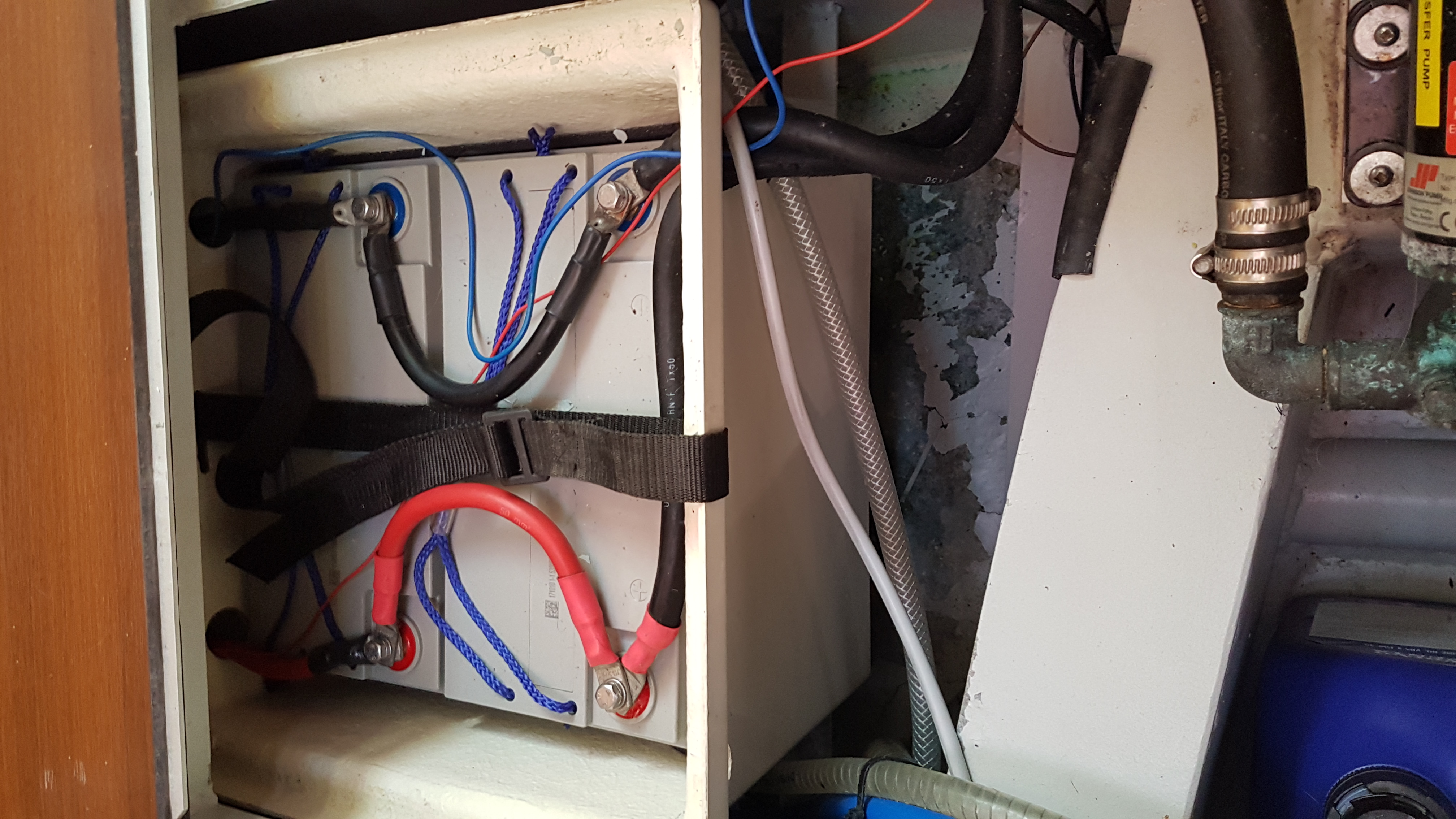

However, the batteries have been charging at 15.75v and they're now cooked. How could this happen? He has sent me a screenshot to show the settings so I don't think he's done anything wrong. The batteries are: VE AGM supercycle 125a x 6.