HI,

So,… In relation to:

b.)

The installation manual (48/5000) states:

| Model |

Battery Capacity |

DC Fuse |

Cable Cross Section 0-5m |

Cable Cross Section 5-10m |

| 48/5000/70 |

200 - 800Ah |

200A |

70 mm2 |

120 mm2 |

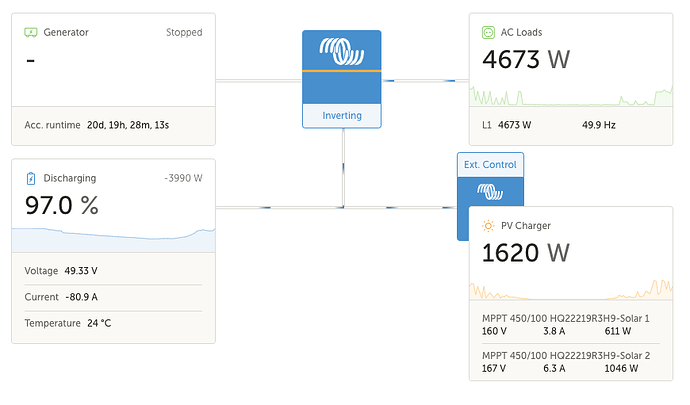

You have installed with 50mm cable (30% under the required cable sizing for this product), this straight away creates a circuit bottle neck between the batteries and the inverter (and your potential 5.2Kw load (immersion (3Kw) and kettle(2.5Kw) - 104% of the service output)). This will increase heat generation in all components in this section of the circuit due to resistance.

ALSO what cable sizes are connected to the Pylon US3000’s. It looks worryingly like 25mm positive and the same for a single negative? These are supplied cables for Pylon US3000.

HOWEVER the manual states recommended discharge current is 37A and it looks like the installation is 3 x US3000’s daisy chained (3 x 37A = 111A), with a single 25mm to the ‘Lynx Power In’? IMHO the final connection to the LPI from the last US3000 should be with 70mm cable too (as for the inverter).

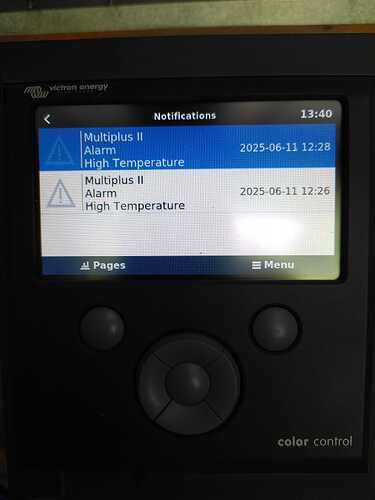

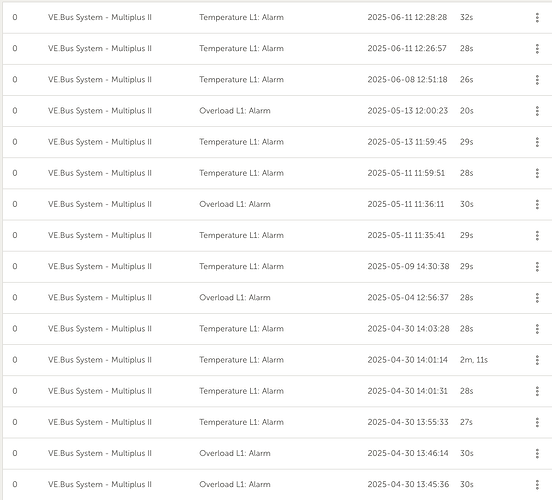

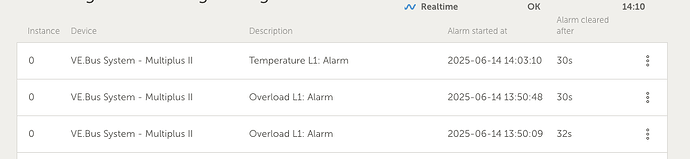

Due to the cable undersizing I would not be surprised to see the inverter enter a low voltage or overload alarm and disconnect.

c.) Am I right in observing that the temperature sensor from the MP is connected directly to the busbars of the ‘Lynx Power In’ ?

Is this is the same busbar that carries all system loads and is bottlenecked by the 50mm cables, and will get rapidly warm under load?

The temperature sensor is primarily for temperature charging compensation, and is meant for direct connection to the battery terminal (also prevents low temperature charging of the battery when correctly configured in VE.Configure).

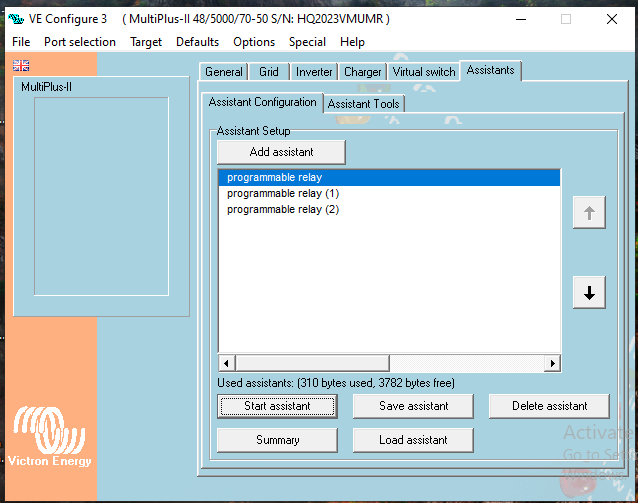

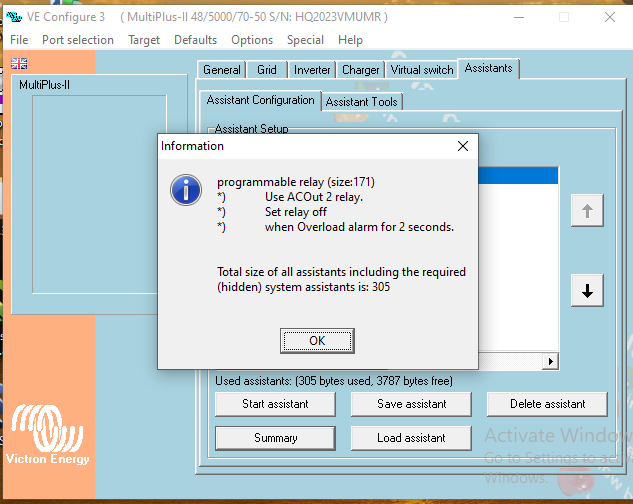

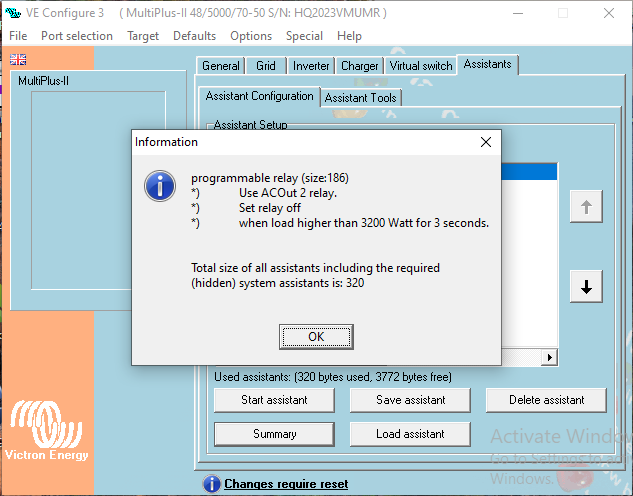

For your assistant we need to see the settings you have input. In VE.Configure → Assistants, select the assistant that you have programmed with the high temperature rule, and then click on the ‘Summary’ button. Screenshot the displayed settings.

My first thing would be to install as per the Victron installation manual for this product, 70mm cables from battery to inverter. Move the temp sensor to the output terminal of the US3000 which connects to the LPI. This should be less than £50 to rectify (cable, crimps, heatshrink) yourself.

If I had spec’d your install I’d have recommend the 48/10000 (due to the potential 7.3Kw load). I’d have installed a 48/8000 with a sigh, and totally advised against the 48/5000 for your use case.

So I would consider an upgrade to the 48/10000, and off-set the cost against selling the 48/5000, before it gets damaged.

A standard domestic kettle will draw it’s load, for half a kettle full (1.5L) for about 4-5 minutes.

We don’t know what volume of water the immersion is heating but 3Kw will be going for 45-150 minutes based on a standard 120L immersion tank (starting water temp, ambient temp, in service draw et. al.) On a 48/5000 that is quite some inverter heat generation over that time with that cabling, then add in the kettle and / or washing machine.

These people offer a great calculator: Water Heating Calculator. - Immersion Heaters UK

As you have a thermal store the target temp will need to be greater than 65C as this is the required temp to kill legionella bacteria, I used 74C in the calculation (my own 55L calorifier gets heated to 85C).