Hello All,

There is a situation where an MP2-3K is used together with a 16S 5kW LiFePO4 battery for providing UPS services in the rare occasions of grid failure.

The battery is charged up to 56.24 V in order for the battery to reach above 56V (3.5V per cell) and balance properly.

So the absorption voltage is set to 56.24V and is kept for 2 hours, time during which the battery balance nicely at no more than 10mV difference between cells.

In this moment, with the use of the Virtual Switch AC input ignore feature, the system is set to charge to 100% SOC with about 0.15C and then to slowly discharge to 30% SOC.

Based on consumption, the cycle is repeating at about 3 days. Charging 6 hours, absorption 2 hours, 72 hours discharge.

But if a grid failure is happening when the system is at a low SOC (e.g. 40% SOC), then the backup time is quite short.

Now the interesting part…

I was thinking to set the float voltage to about 53.12V (3.32V per cell) in order for the battery to indefinitively keep a stable state of about 85% SOC and be ready enough to provide power for short emergencies.

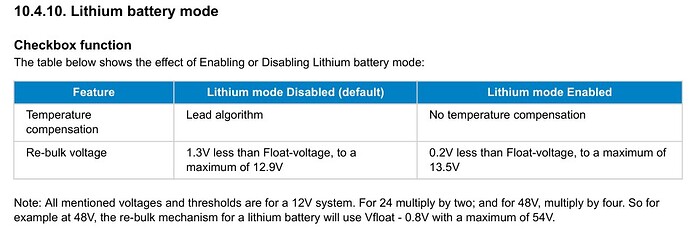

Because the MP2-3K charger section in the VE configure doesn’t provide for LiFePO4 batteries things like storage voltage and re-bulk voltage, how the system will behave in this situation?

Will it enter storage mode or not during the waiting periods between grid failures? If yes, at which voltage? Is there a storage voltage setting for LiFePO4 batteries, that can be modified?

Will it enter re-bulk mode? If yes, when? Because reabsoption can be set, both as period and duration, but re-bulk no…

I believe that keeping this way at about 85% SOC is better, because it can provide longer back-up power if grid fails.

Also, the 85% SOC is quite a conservative SOC and keeping the battery for longer periods at these voltages/SOC is not hurting the battery.

I want to keep the system as clean and lean as possible, so no ESS assistants and no Node-Red solutions, please.

Thanks in advance for any opinions!