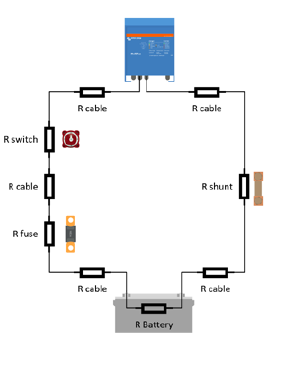

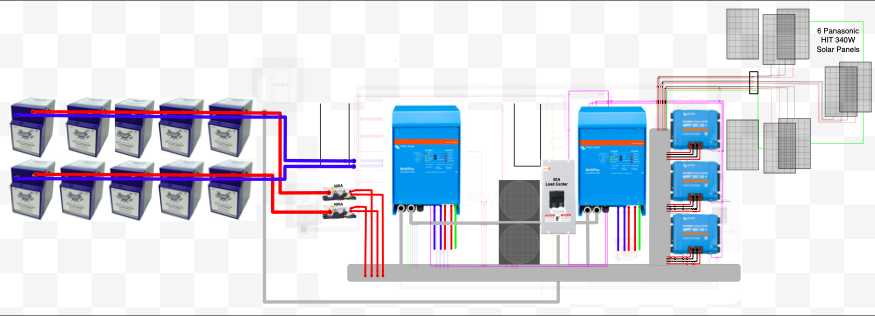

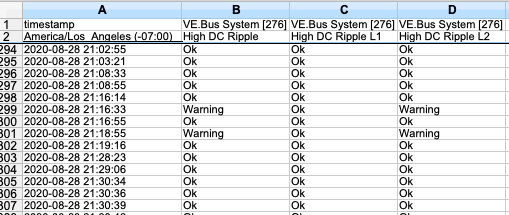

I would like to put this out to the community to see if I am missing anything in the way I currently have my system wired before I power everything up

12VDC side

Batteries

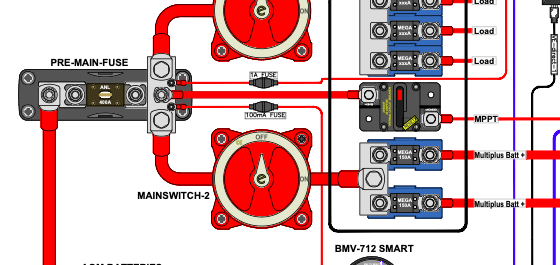

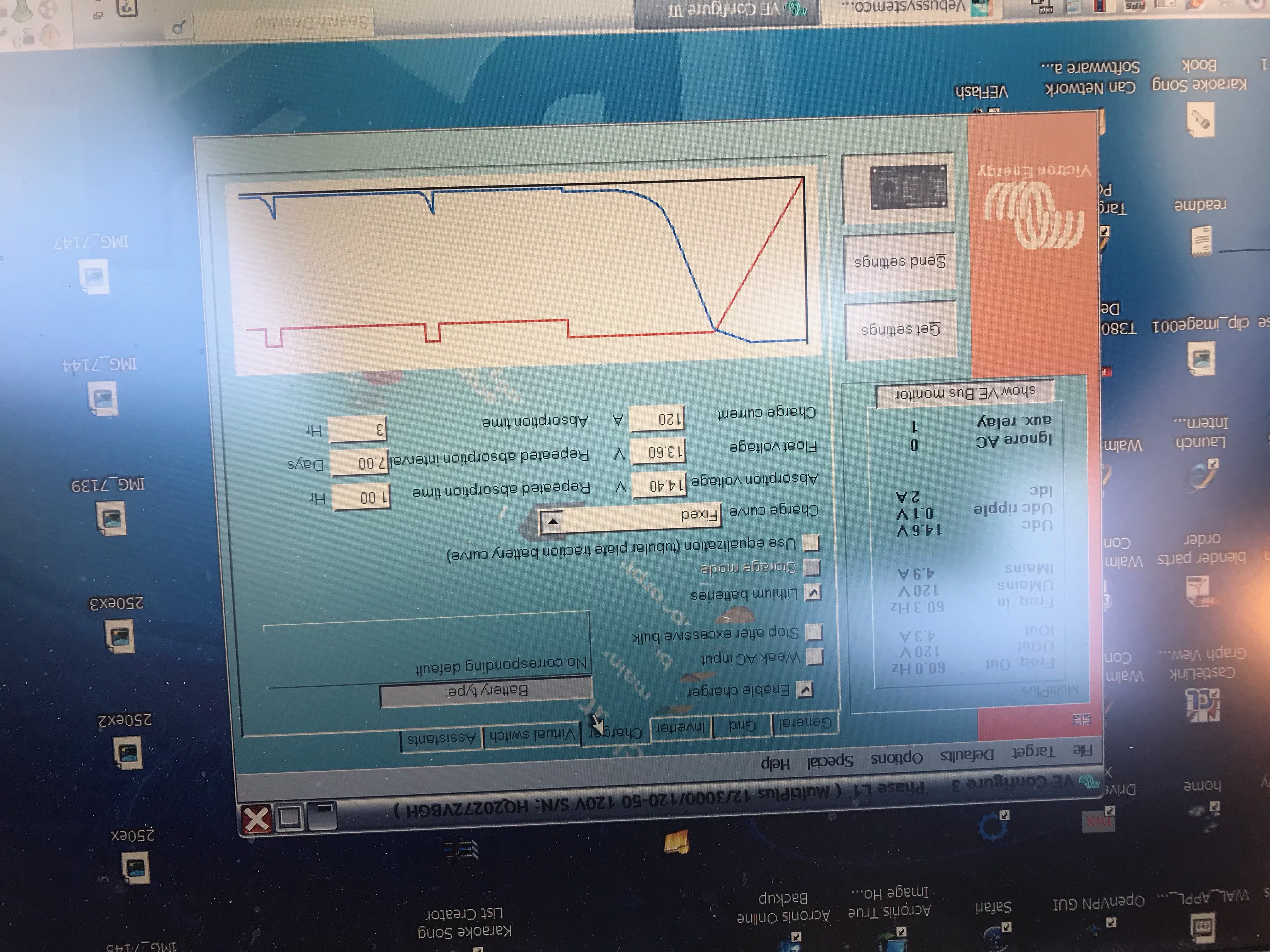

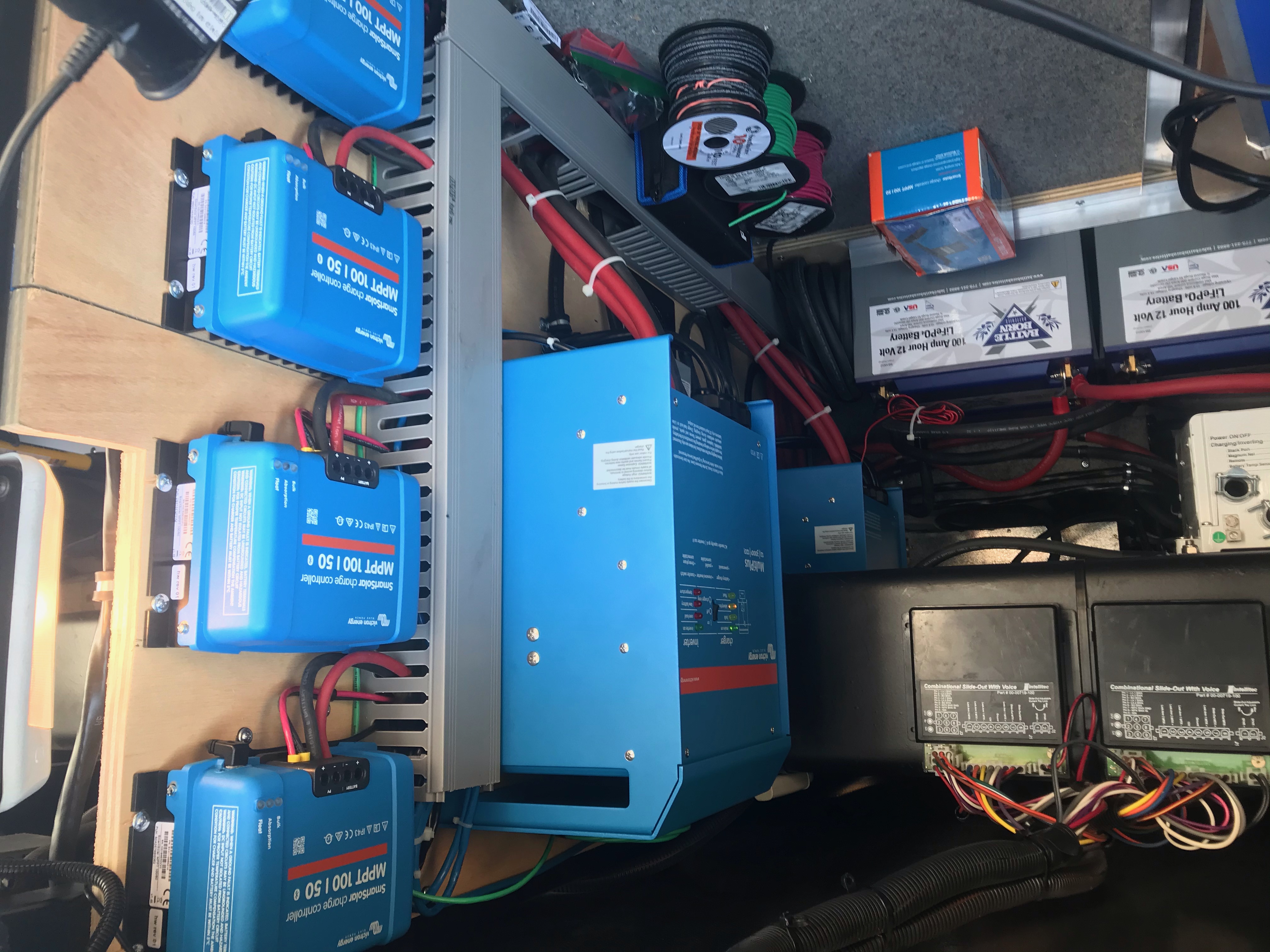

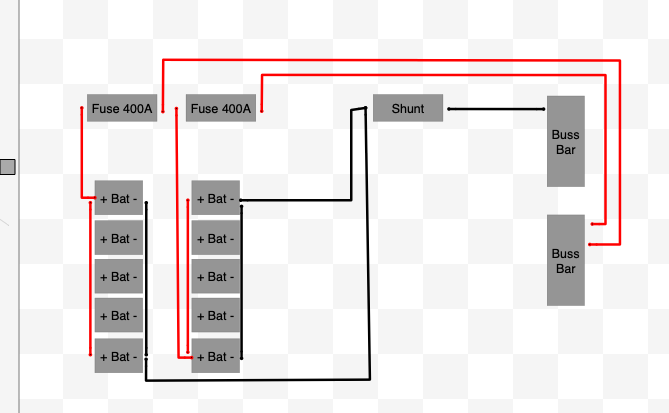

I have 10 battleborn lithium batteries divided into two banks interconnected with 4/0 cables.

Each banks positive goes through a 400 amp class t fuse then through a battery disconnect and over to a 1000 amp buss bar.

Each negative goes through a smart shunt and then to a 1000 amp buss bar.

Cables are within inches of being the same length slight variance due to placement of switches

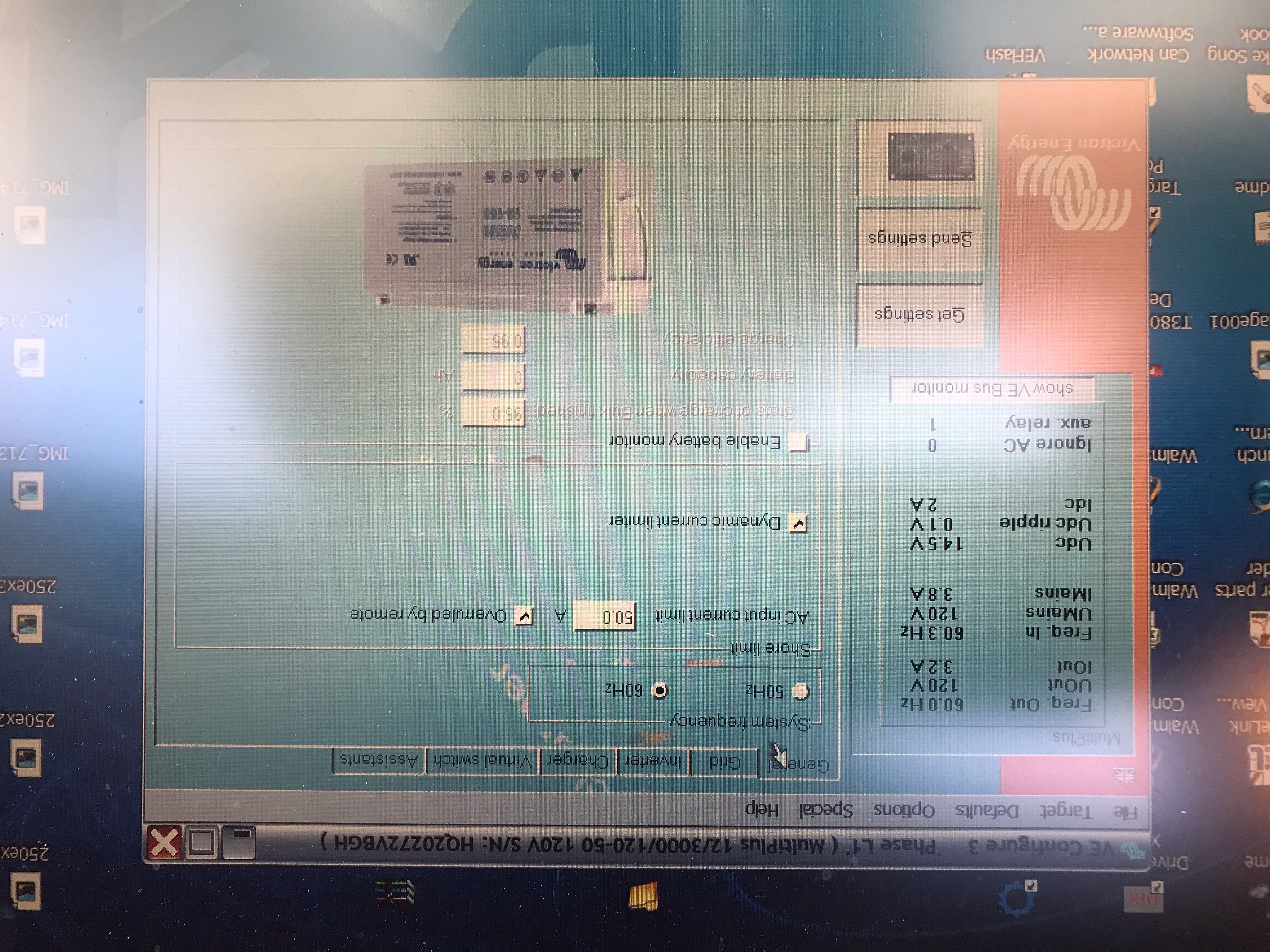

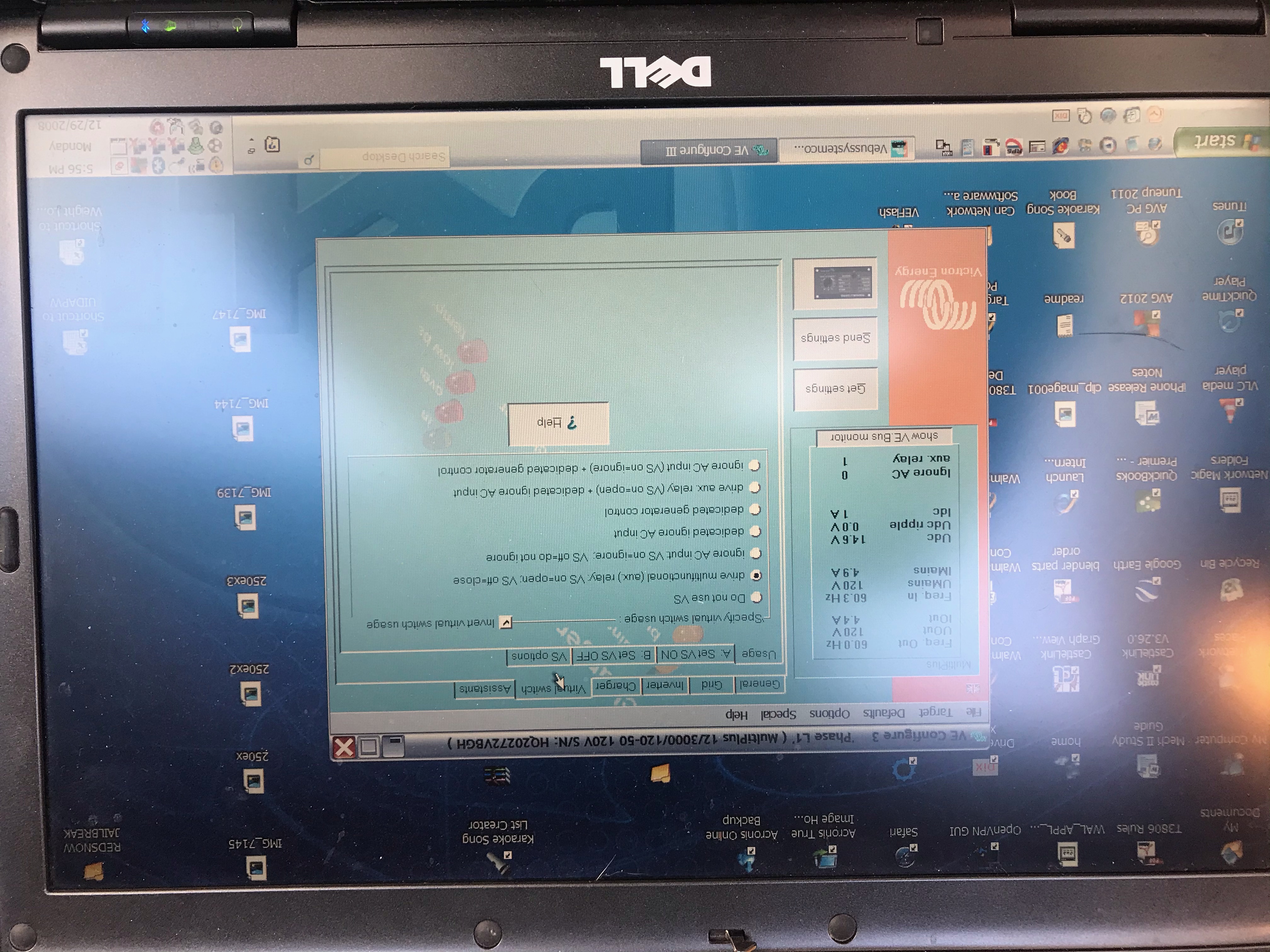

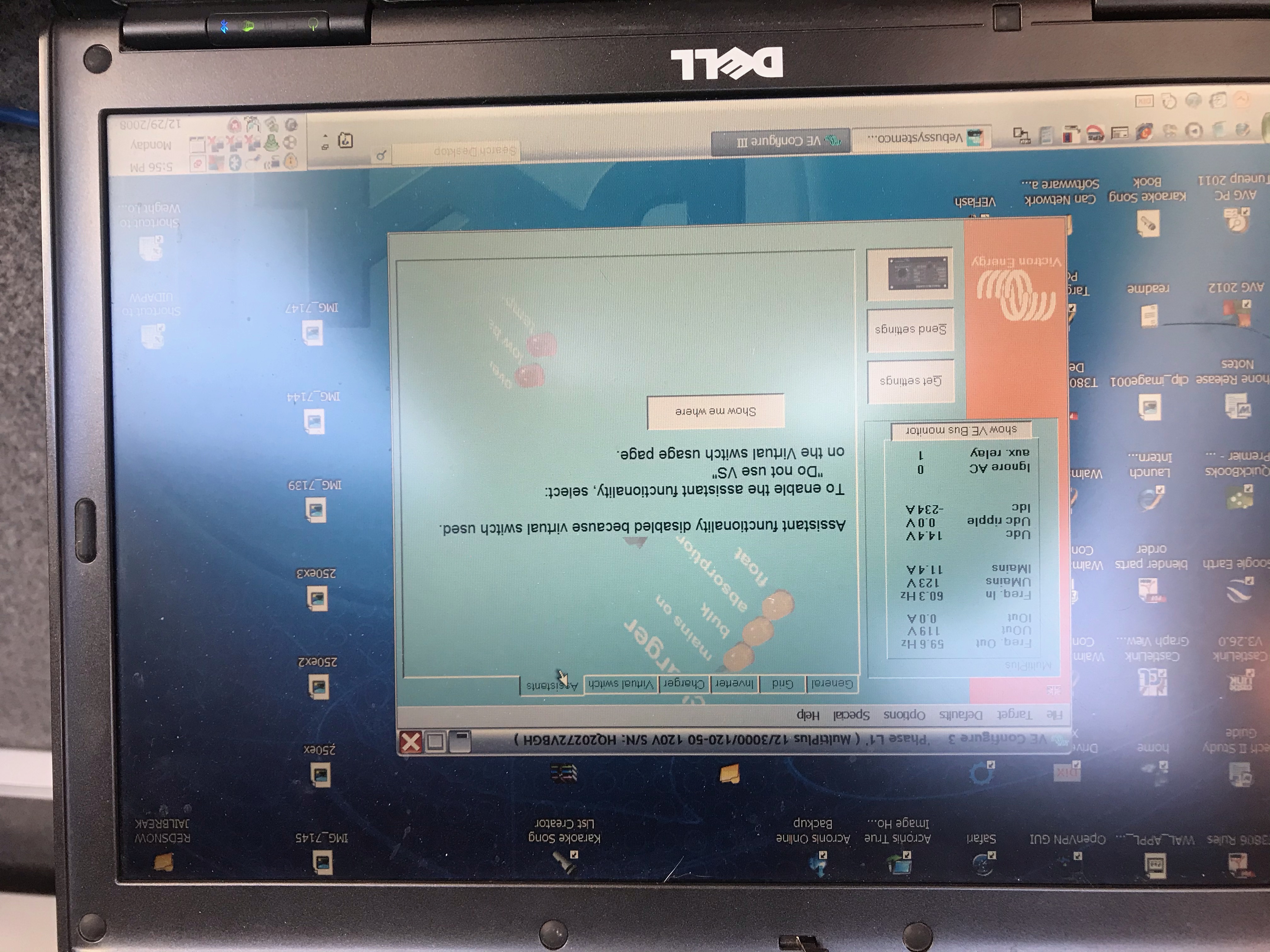

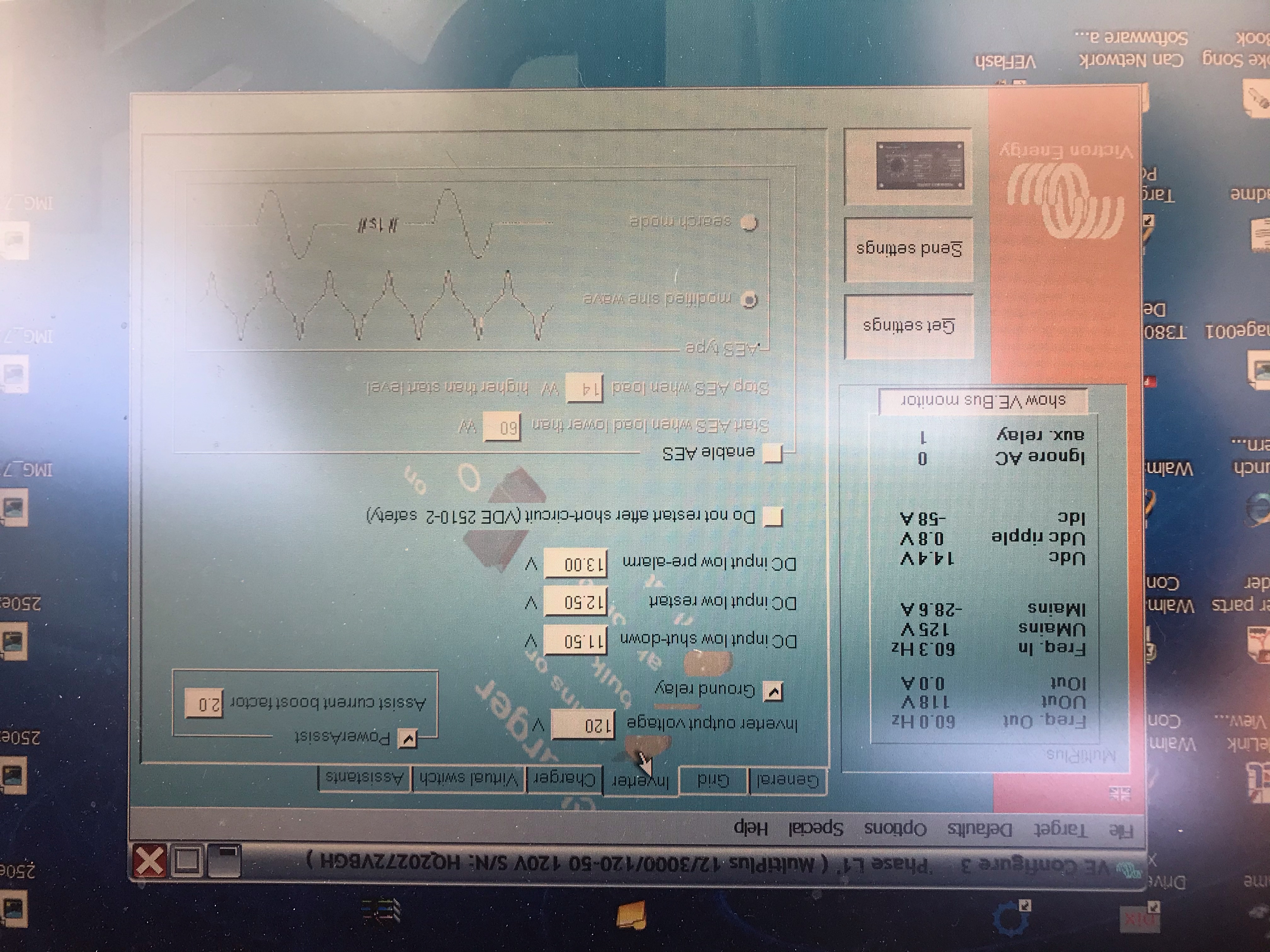

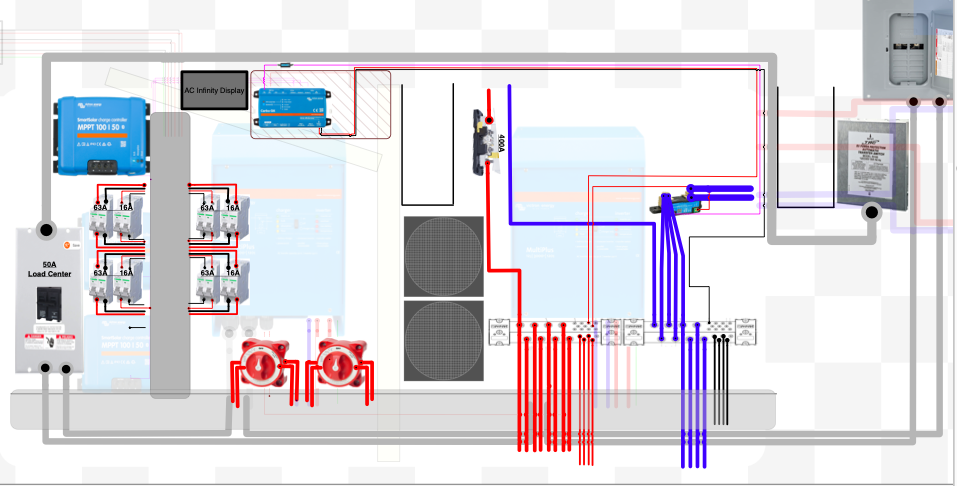

Inverters 2 Multiplus 120v 3000

Each inverter positive and negative go directly to the the buss bars using two 2/0 for both pos and neg

Each inverter casing is grounded to the motorhome chassis local to the inverters

Cables are the same length

Charge controllers 100/50 x 4

Each pair of solar panels go through din rail pos & neg breakers to the PV input on the controllers over 10awg wire. The wire calculator I used was border line 10 or 12 so I went 10

Each output of the controllers battery side goes through a din rail pos & neg breakers then on to the buss bars over 6 awg wire

Charge controller chassis grounds are daisy chained and terminate on the motorhome chassis at the same point as the inverters

Cables are the same length.

Motorhome DC distribution

I am using the existing motorhome 3/0 inverter cables to supply voltage back to the original battery compartment where the original chassis ground is, dc distribution and alternator cables go to.

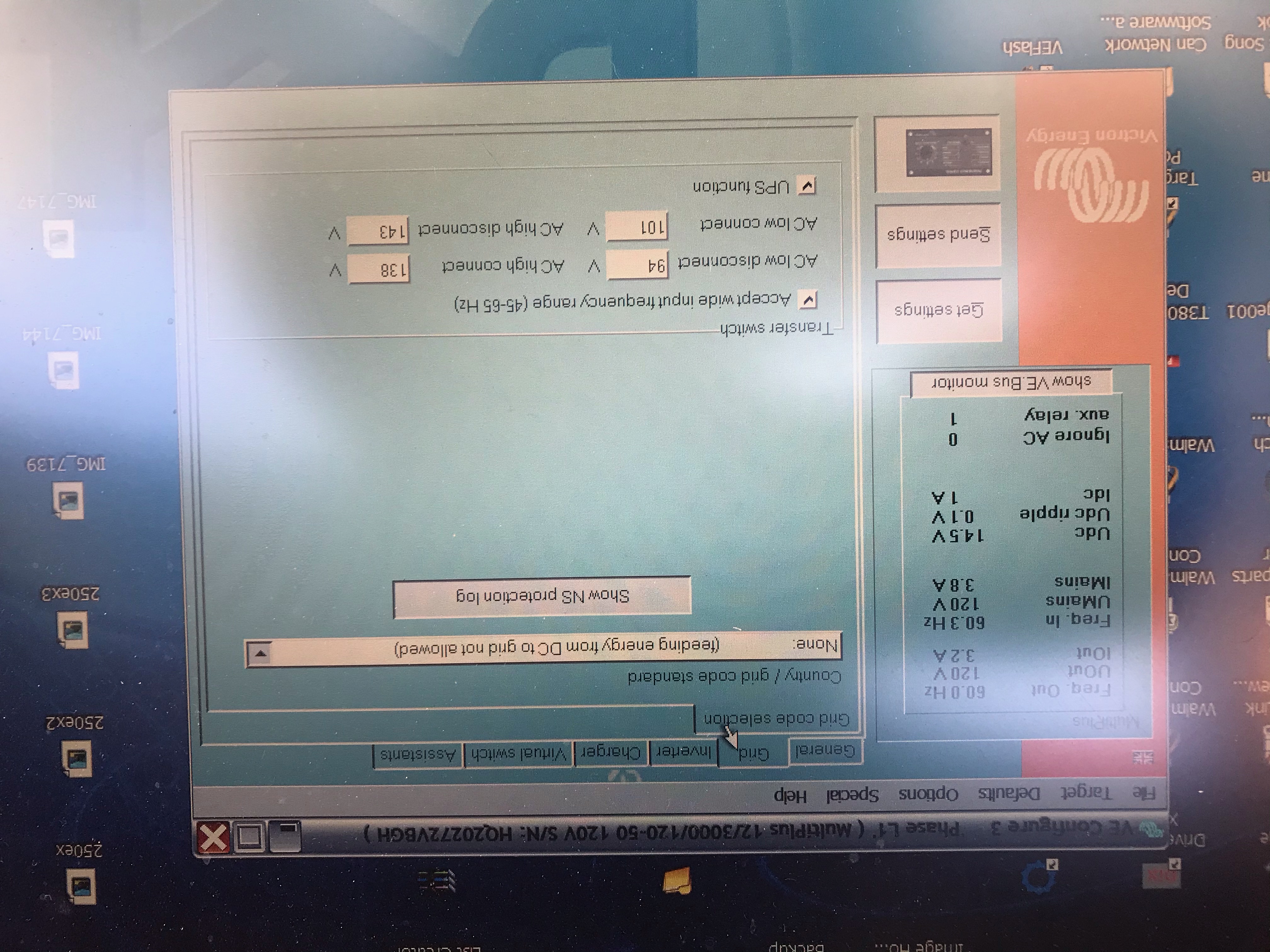

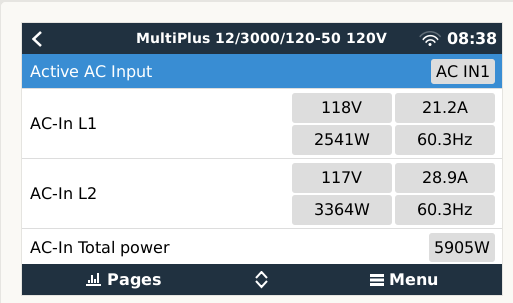

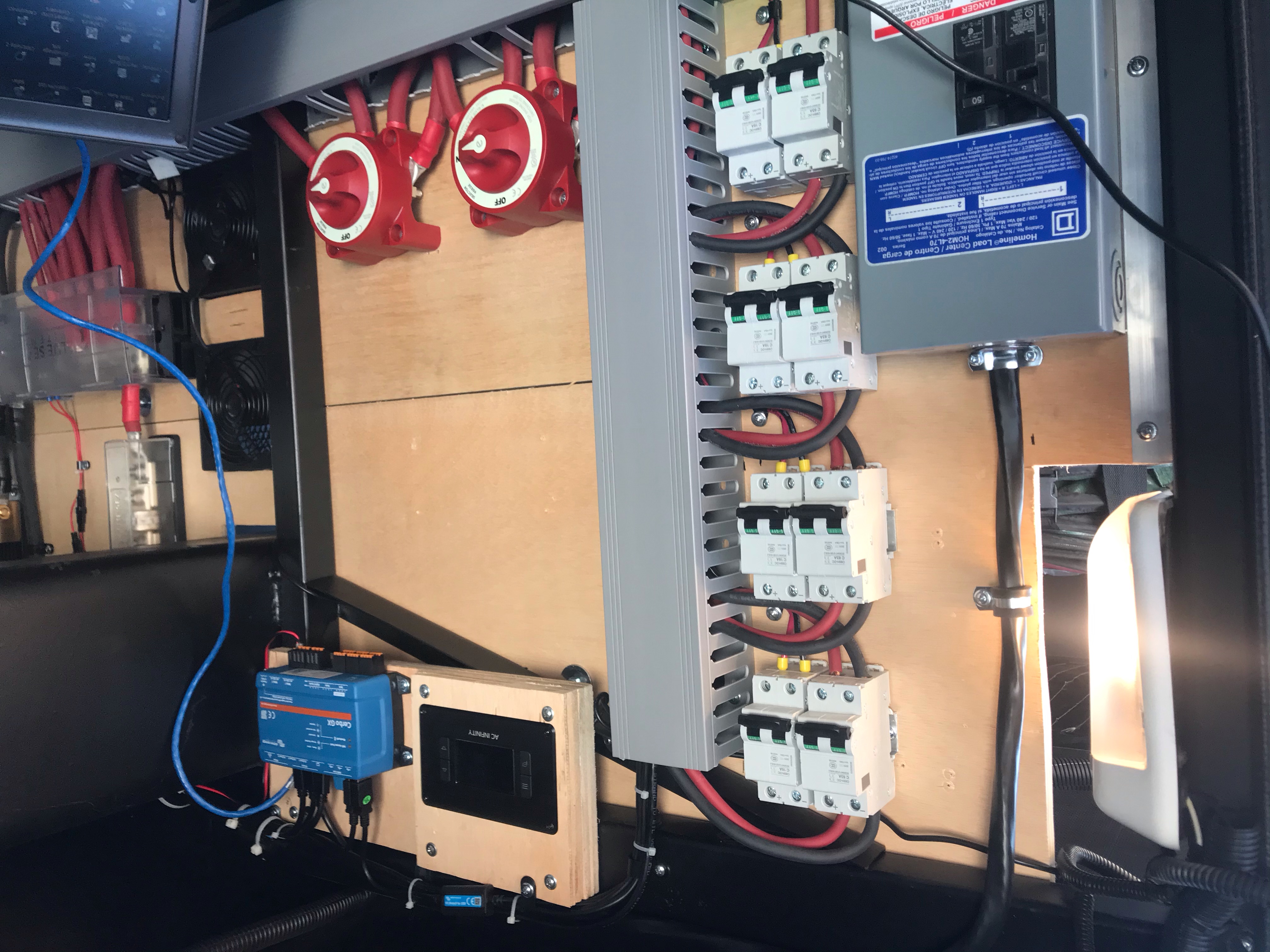

AC 120v 50amp

AC comes in from either shore power or the generator through the transfer switch over to a double pole 50 amp breaker then the ac is split into two circuits 1 going to each inverter.

AC1 out on each inverter is fed to another 50 amp double pole breaker and then continues to the main AC distribution panel for the motorhome each inverter feeding one leg of that distribution panel

AC cabling is within a couple feet of being the same length. Not sure how critical the symmetry is when running separate legs of the ac panel since the inverters will not share each other’s load.

Is there anything I am missing here?

Thanks Richard

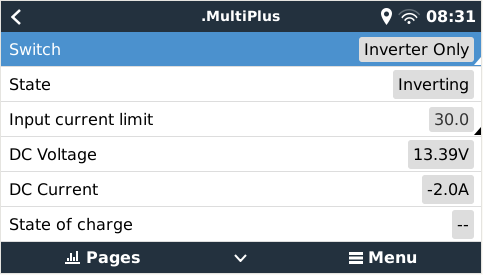

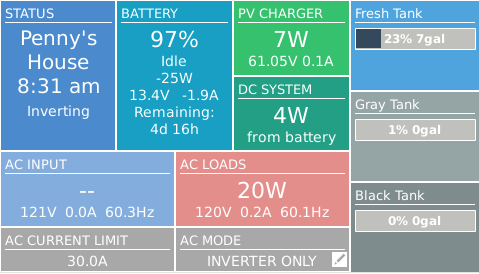

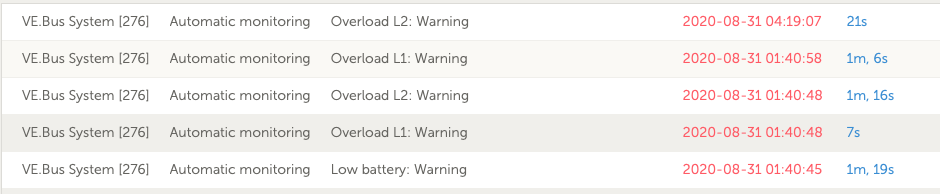

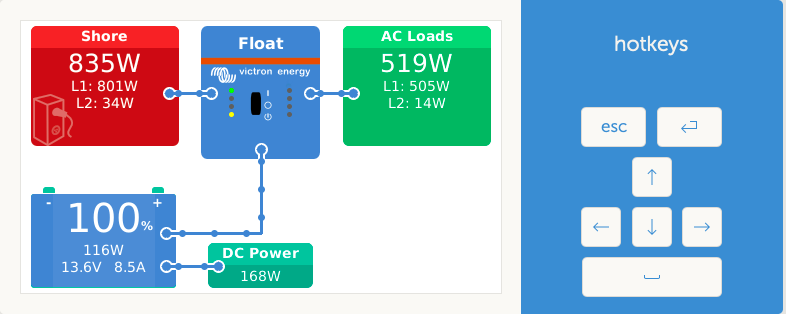

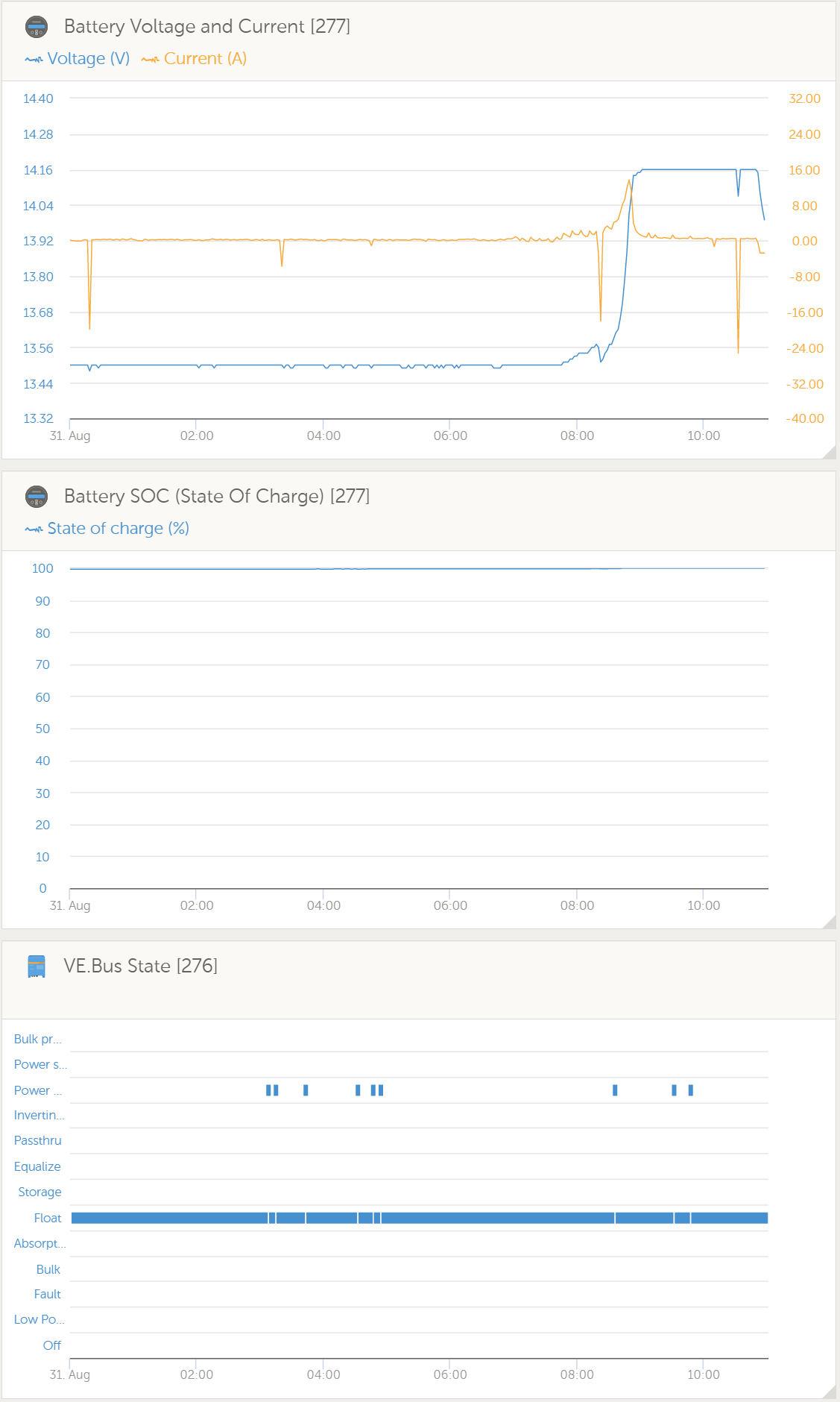

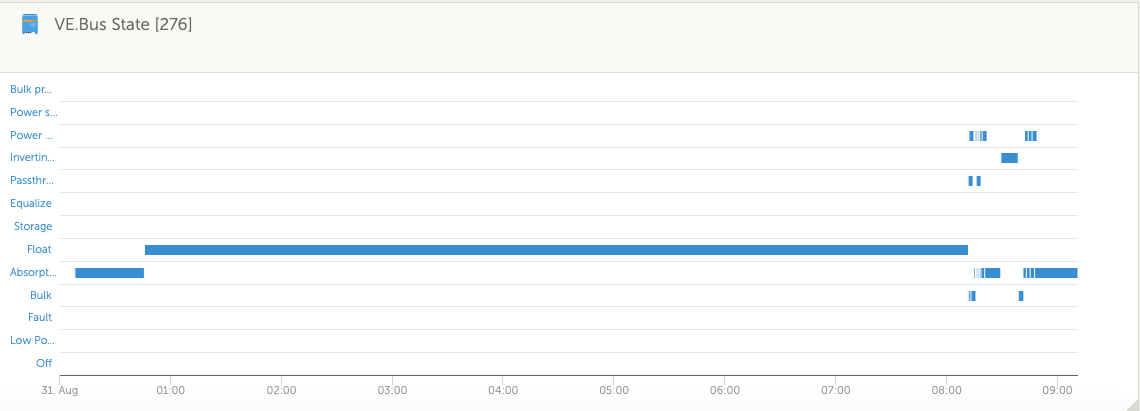

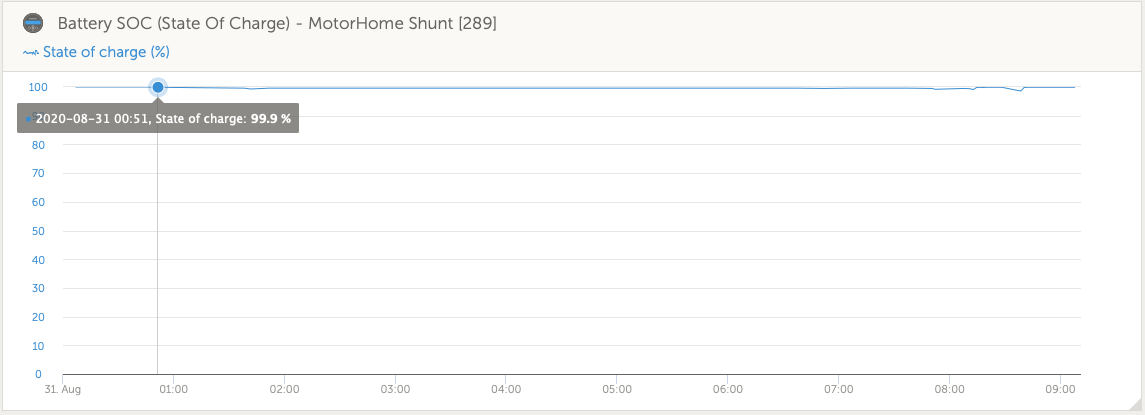

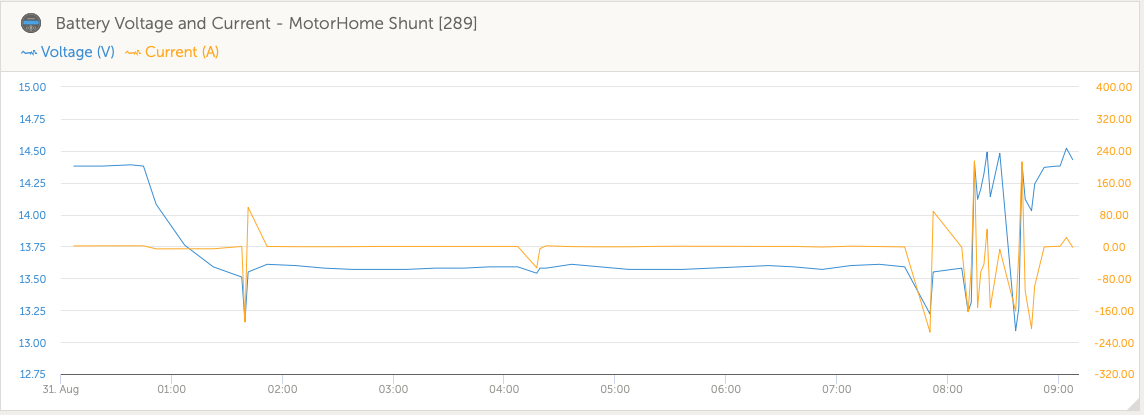

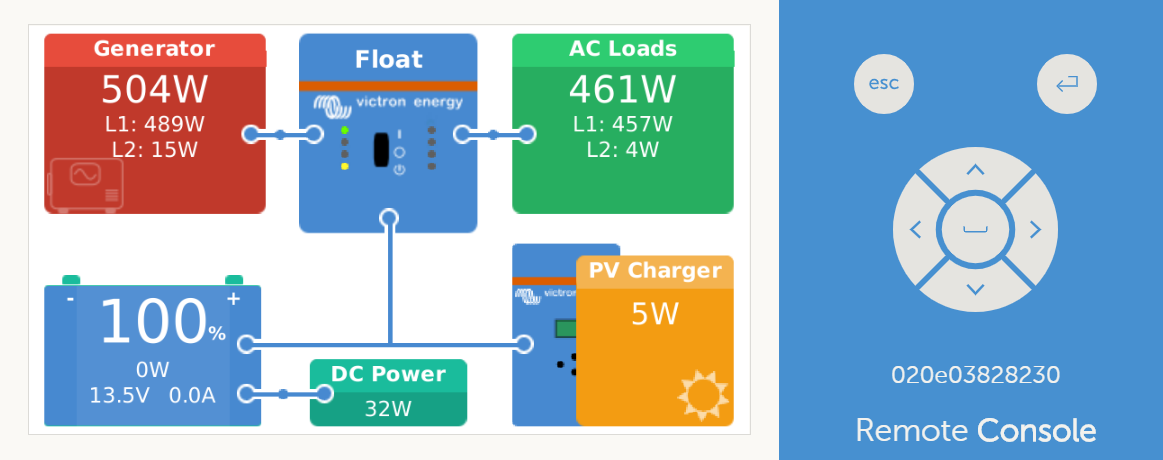

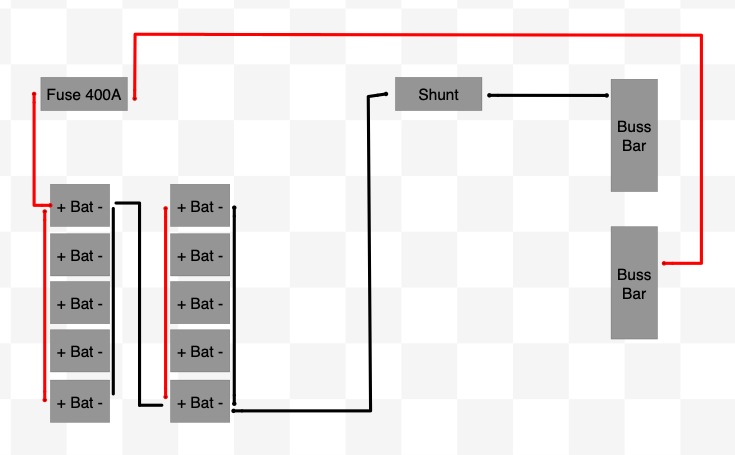

Second Image is when I transferred back to Shore Power. My Oasis Hydronic Heater may be using some of this 12v load for its pumps and such but why does it increase as I am inverting. Puzzled I am. Any Wisdom would be appreciated

Second Image is when I transferred back to Shore Power. My Oasis Hydronic Heater may be using some of this 12v load for its pumps and such but why does it increase as I am inverting. Puzzled I am. Any Wisdom would be appreciated

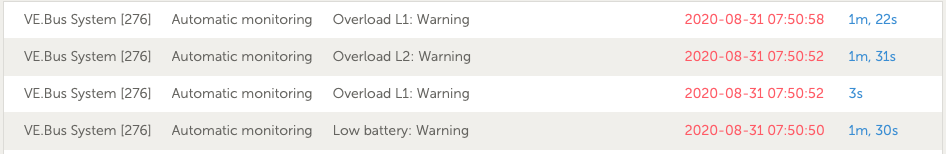

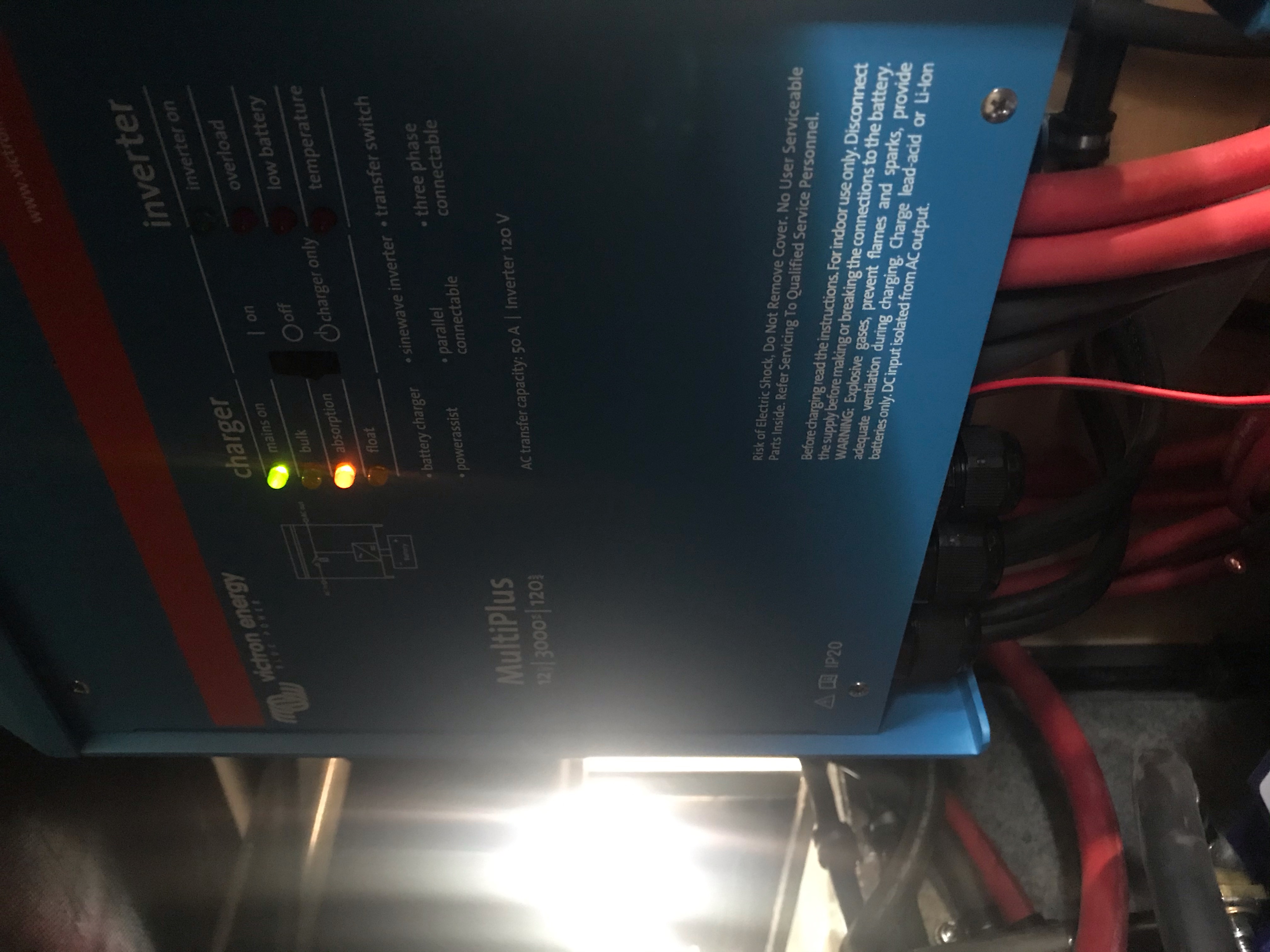

And another low bat and overloads to follow

And another low bat and overloads to follow

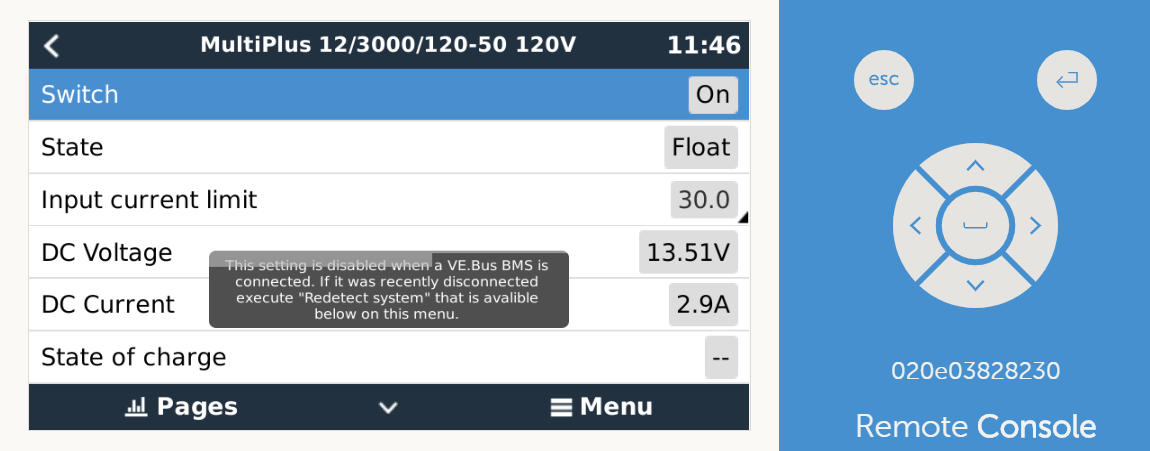

Inverter 2

Inverter 2 Inverter 1

Inverter 1

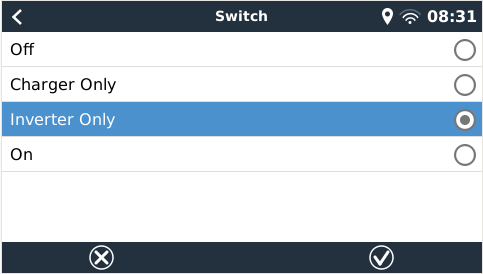

Yes exactly only mine has 2 multis I will be switching. Thanks for the diagram from the Mortons.

Yes exactly only mine has 2 multis I will be switching. Thanks for the diagram from the Mortons.