Hi there,

I'm a little bit confused - haha :D

Preliminary information

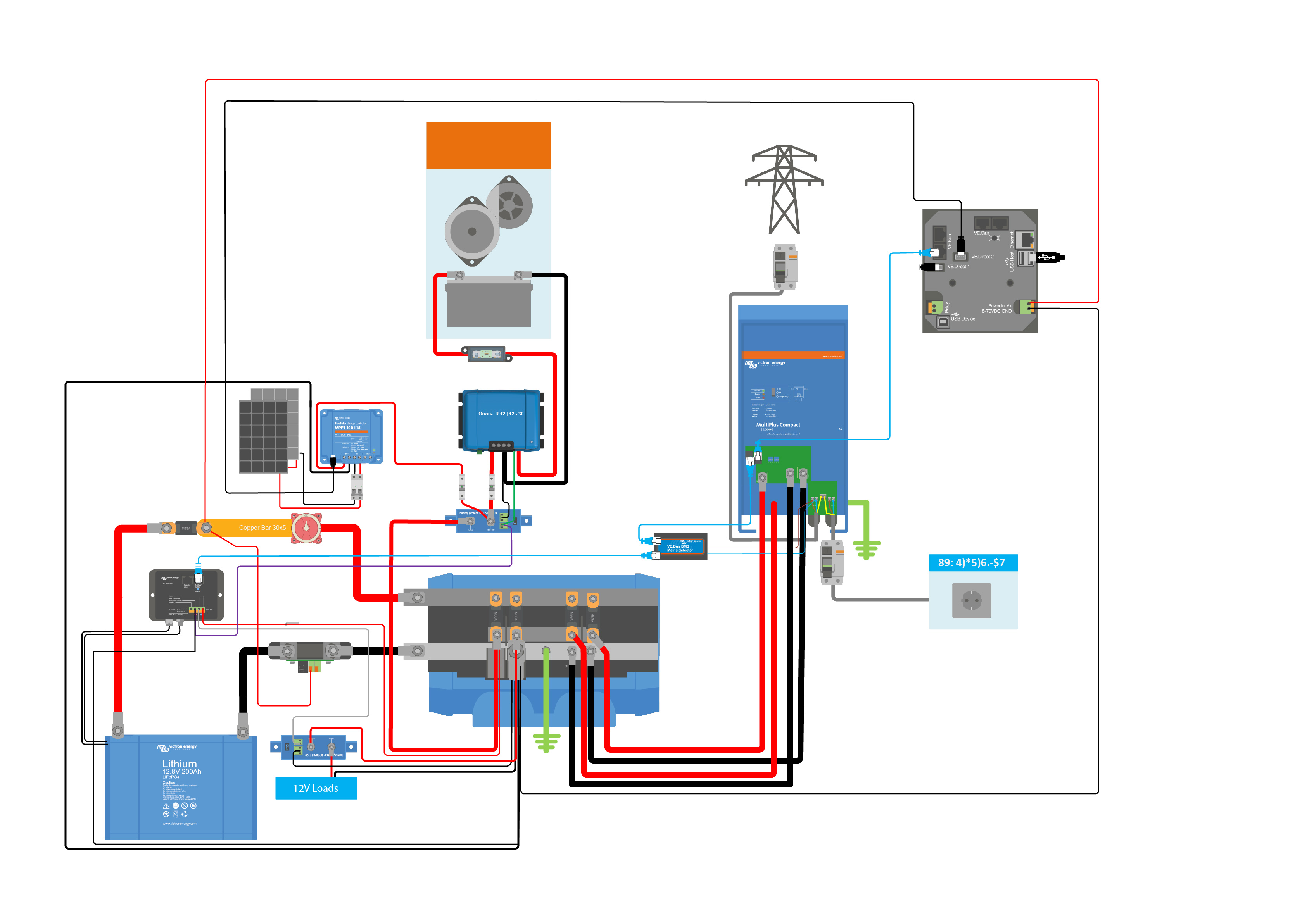

My electronic setup basically looks like the automotive showcase from Victron with some slight differences. Key features:

- 400Ah Victron Smart Batteries

- 3000VA Multiplus

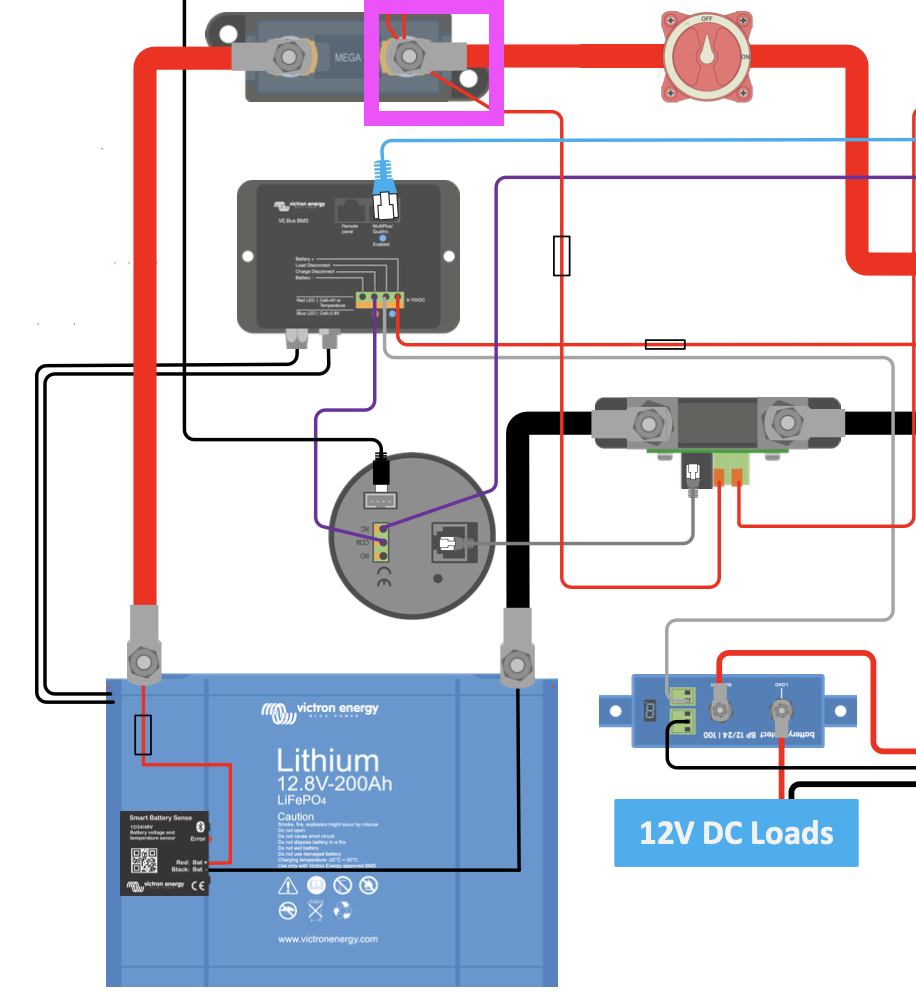

- Lynx Distributor to connect the Multiplus (and 12V loads) to the batteries

- 2x 95mm2 cables to connect the Multiplus to the Lynx Distributor

- Copper bar to connect the main switch with the fuse

Example Use Case & Problem Description

My 3000VA Multiplus is mainly used for cooking. In the following scenario, I used a 2kW electric heater in the early morning because my heating system was not ready at this time. (Not a use case anymore, and just for a better understanding of what was going on).

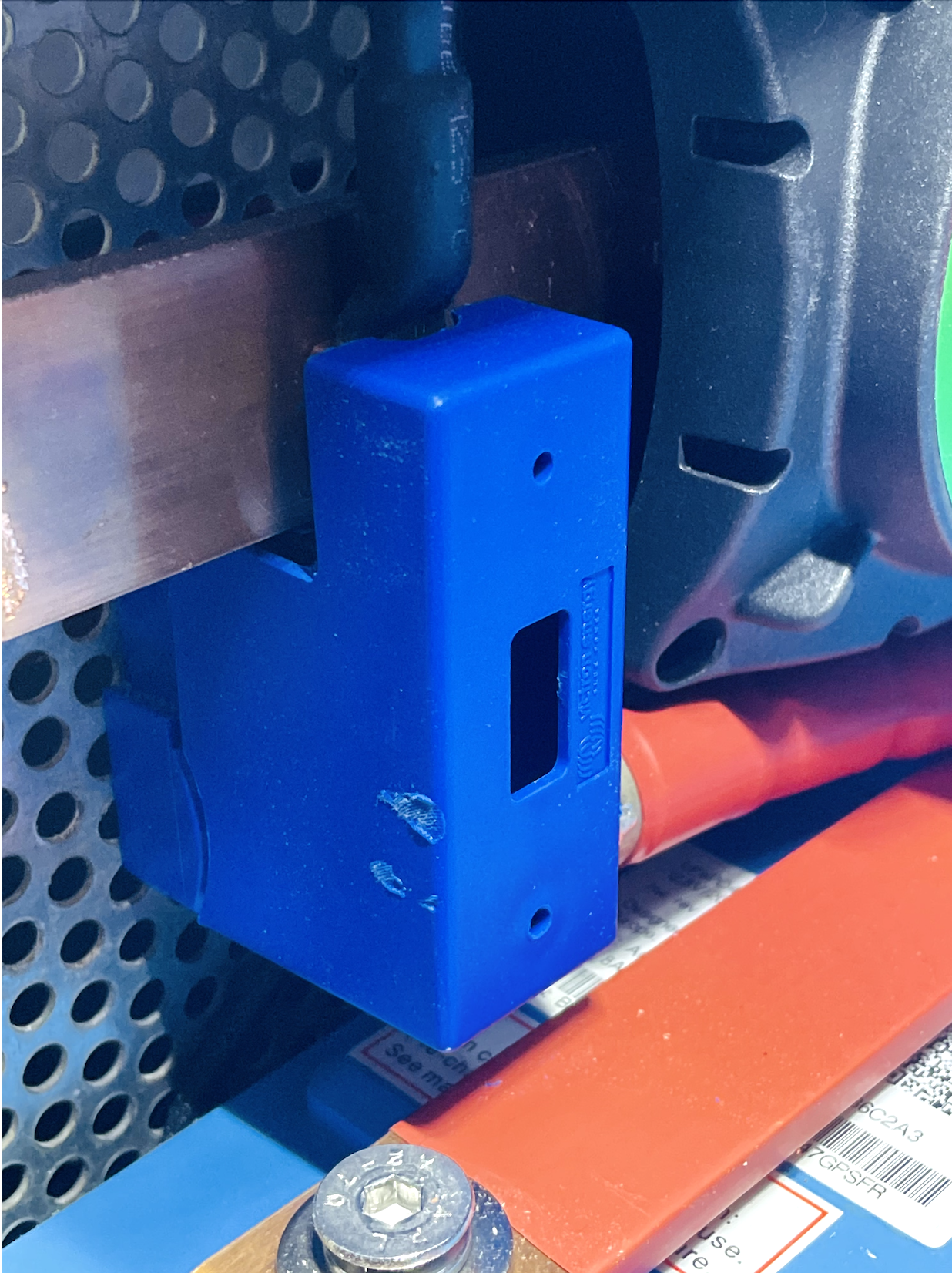

As the electric heater was warming up the inside of our Sprinter van at half power (1kW) for 90mins, suddenly the Cerbo GX showed an over-temperature warning. I got up and took a look at the system. And right at the mounting point of the main system fuse (see the mark in the image below) the copper bar I used to connect the main switch with the fuse was extraordinarily hot (60°C).

I indeed did a test of the whole system months before and did know that this point was going somewhat of an issue as it will heat up first if the system is under high load. So I placed the Multiplus temperature sensor there, just in case. And, well, the alarm struck.

Thoughts & Question

Now I was thinking about how to solve this. (I also asked a friend how is an electrician, but for households and not for 12V/24V systems.)

I'm not quite sure if the problem exists because of the huge load that needs to "get through" this single fuse? Or can it be the different materials the fuse and the copper bar are made of that are causing friction and therefore this point heats up? Because all other parts of the system aren't even hot - sure - they are warm, but not hot :)

So, how about replacing the one 500A MEGA fuse with two 250A fuses to split the load like it is done with the Multiplus connection to the Lynx Distributor? I can't find any answers on this via Google or here.

So, what do you think? Any suggestions? Alternatives?

Thanks in advance

Fabian :)

P.S. Here's a picture of my setup :)